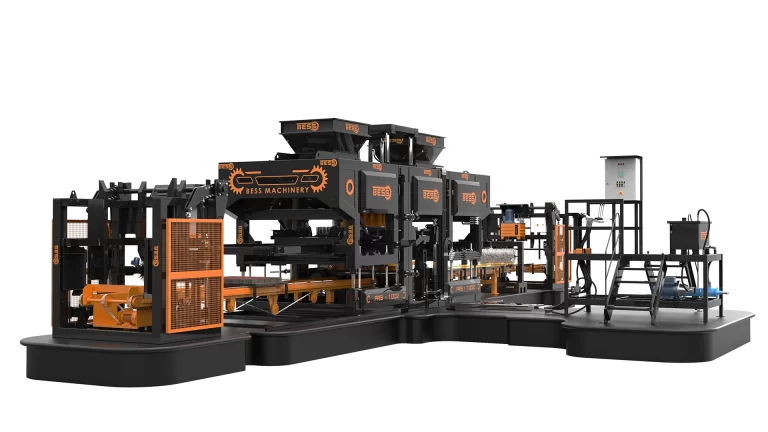

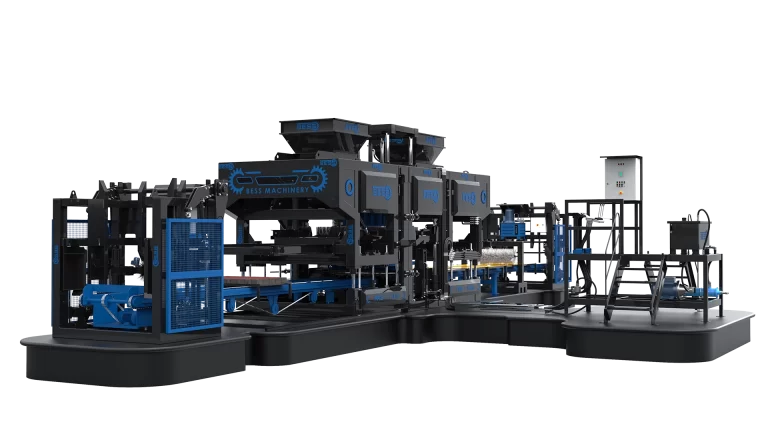

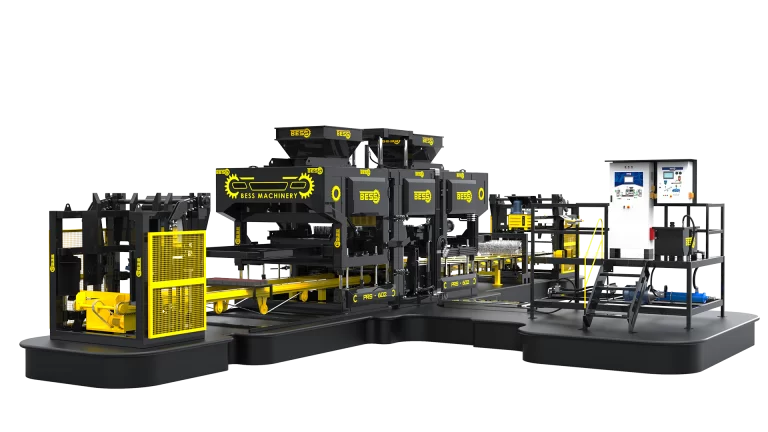

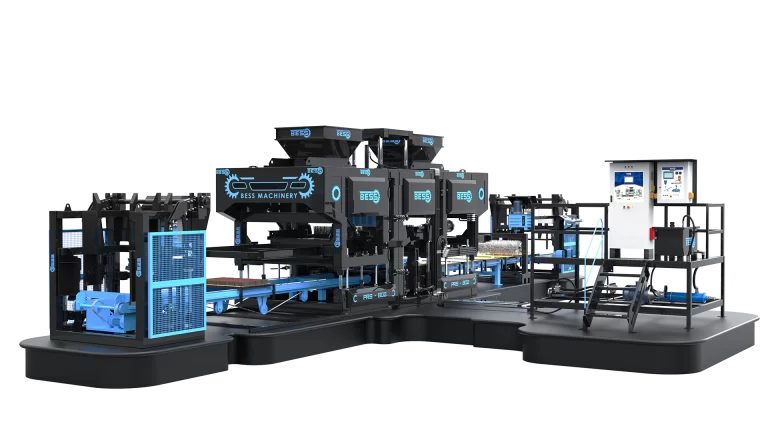

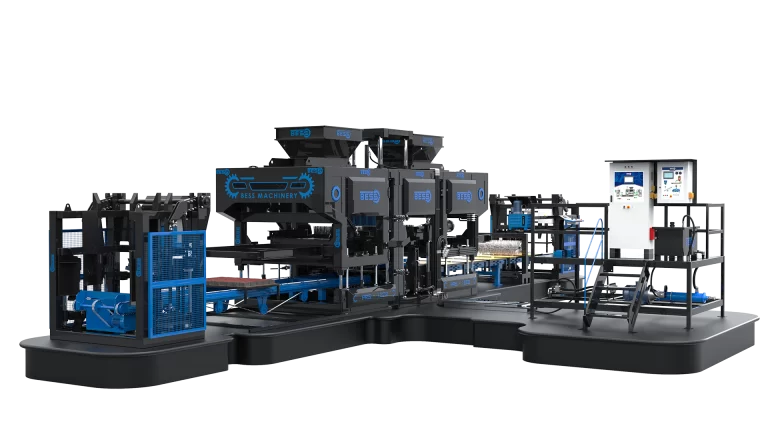

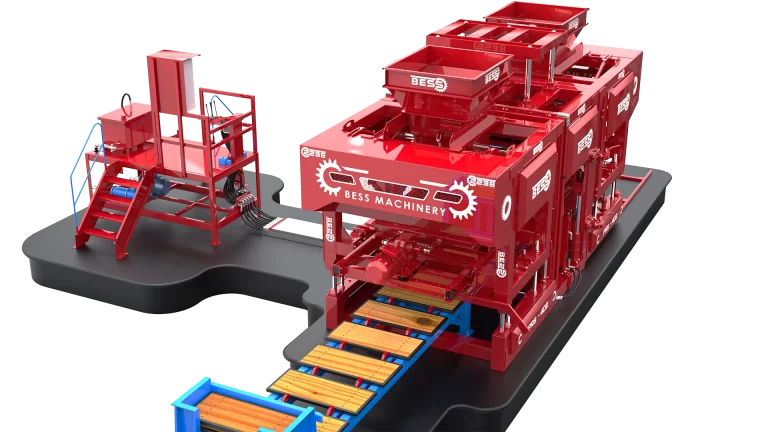

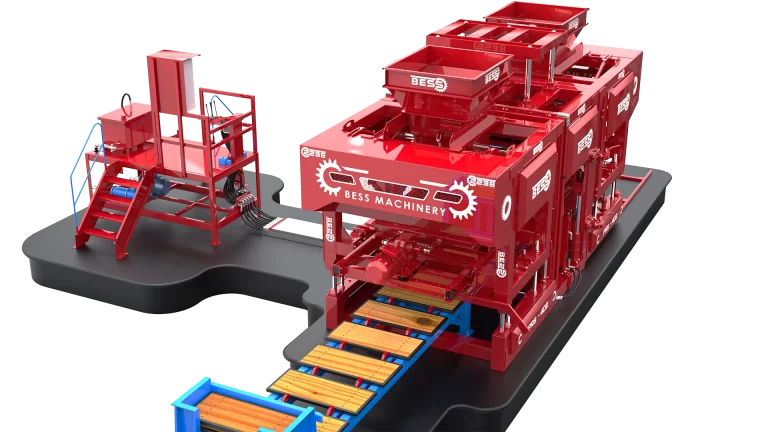

PRS 402 Semi-Automatic

Paving Block Machine

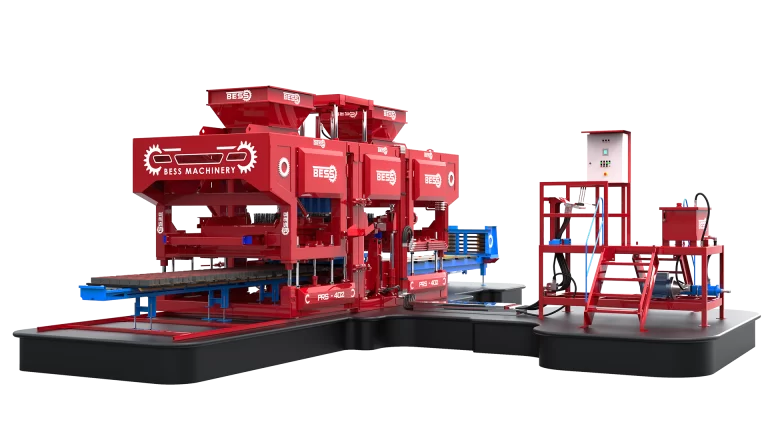

The PRS 402 semi-automatic paving block machine is the smallest capacity machine in the PRS family.

With its manual pallet carrying system and operator-controlled features, you can easily produce 300 m² of face mix paving blocks (double-layer paving blocks), 4,000 to 8,000 concrete blocks, hollow floor blocks (Asmolen), curbstones, and many other types of products in 8 hours. This machine is ideal for small projects and will be your most valuable assistant in areas with low labor costs.

The hidden engine of your projects! Small, powerful, and always efficient.

PRS 402

Installation and Operational Details

- Semi-automatic, operator-controlled system

- Manual pallet transport

- Total personnel needed: 7 people

- Suitable for 24-hour operation

- Recommended area: 2.000 m²

- Concrete foundation required for the machine: 300 m²

- Roof covering not necessary

- Total energy requirement: 50 kW

- Recommended generator power of the plant: 175 kVA

- Number of containers required for transportation: 1 x 40′ HC and 1 x 20′ DC containers

Strength, Reliability, and Efficiency All in One

The PRS 402 semi-automatic paving block machine is built with the power of technology to prioritize performance and reliability. It is designed to offer customized solutions to meet your needs and optimize your workflow. discover the full potential of this advanced technology machine by reviewing detailed technical specifications…

01

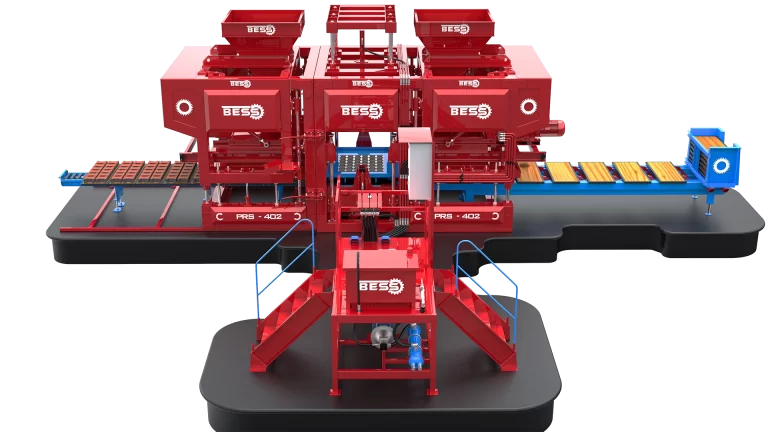

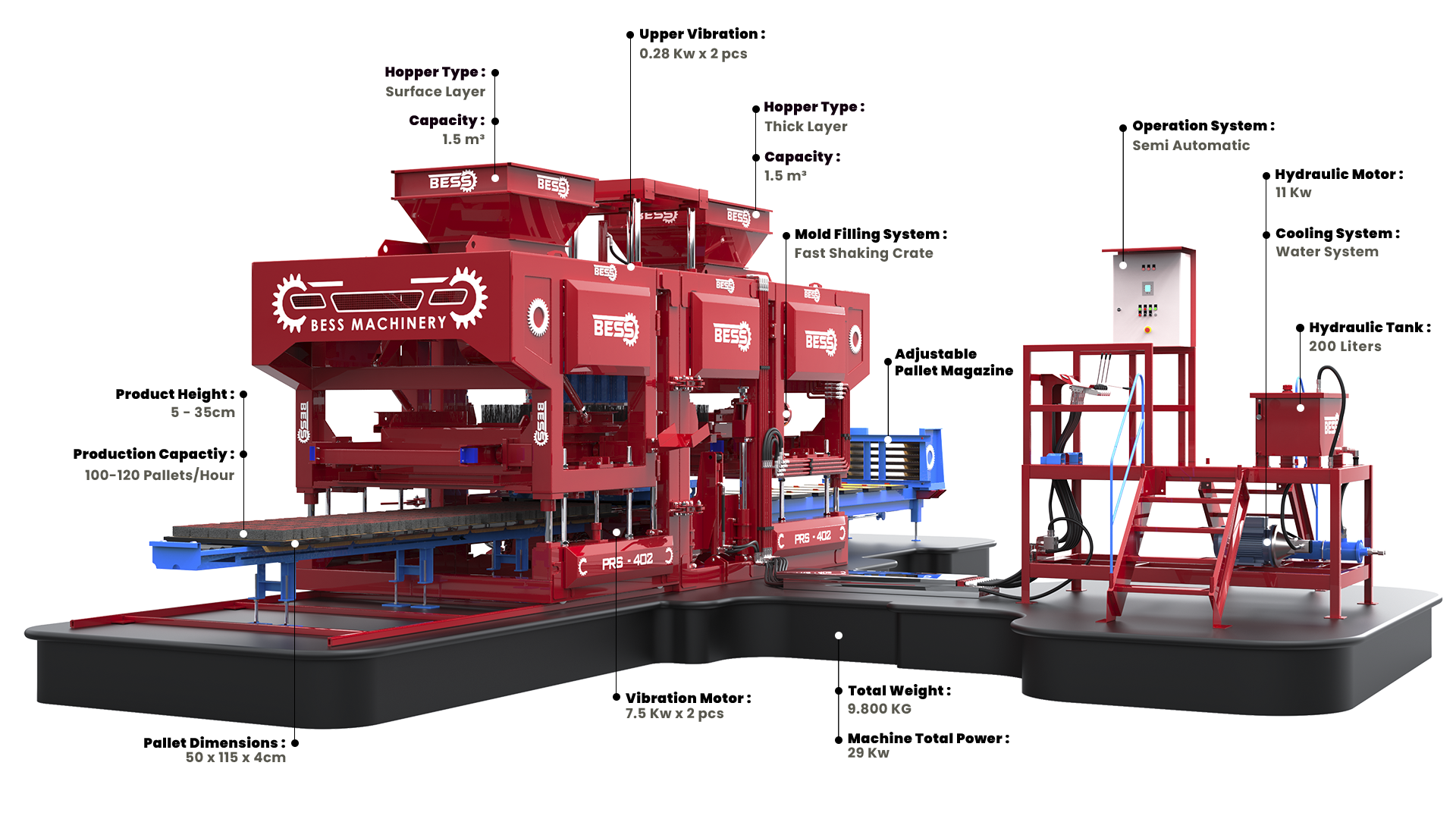

Double Hopper Design Double Layer Premium Production

- Production of double-layer paving blocks and curbstones in various colors and features

- Smooth surface with top vibration

- Ability to produce polystyrene concrete blocks (Styrofoam concrete blocks)

- Multi Color system block production option

- Fast production thanks to special design

- Easy maintenance and mold change due to moving hopper design

02

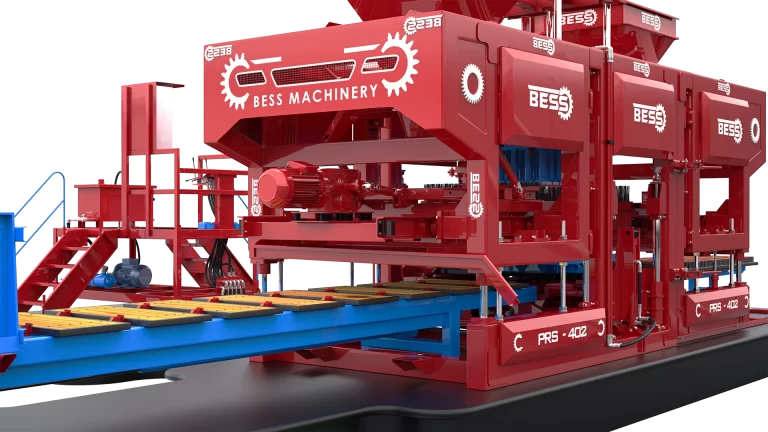

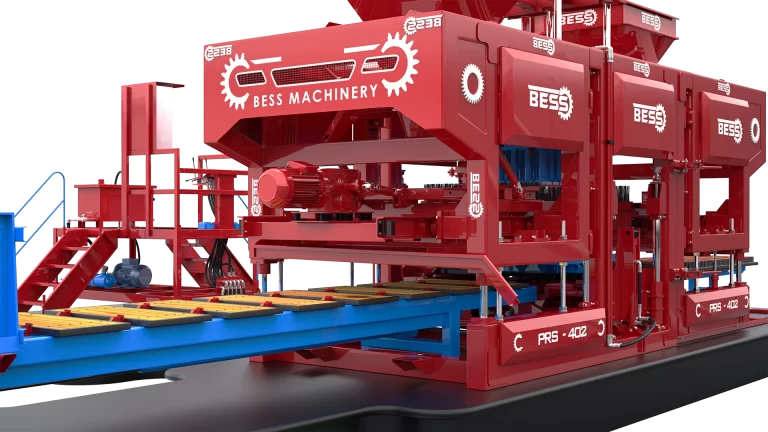

Special Design Reinforced by Modern Technology

- Designed in international shipping dimensions: 225x520x320 cm

- Capable of producing concrete products from 5 cm up to 35 cm in height.

- Reinforced chassis supports: 150x150x5 mm

- Large-capacity mortar hopper with support: 1.5 m³ x 2

- Additional vibration damping wedges

- Special rubber wedges to reduce impact

- Replaceable steel design for wearing surfaces

03

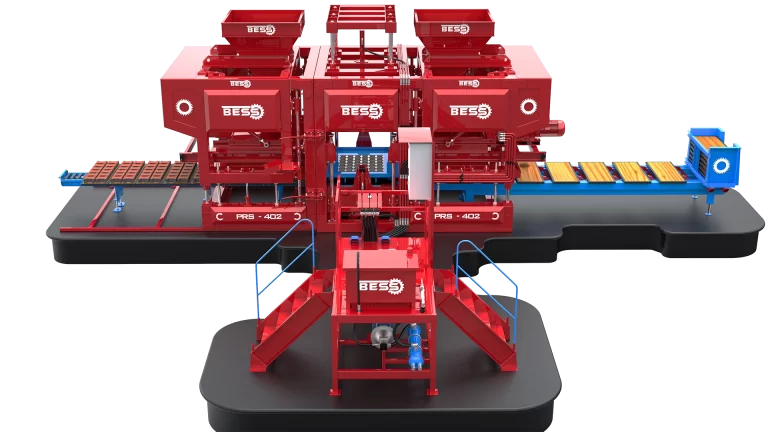

Modular Vibration System

- Vibration motors equipped with special cooling fans

- Synchronized vibration system: 7.5 kW x 2 (80 kN)

- Replaceable vibration table top layers

- Compatible with various pallet types and sizes

- Automatic belt tensioning system

- Adjustable vibration for different production types

- Easy maintenance and servicing

04

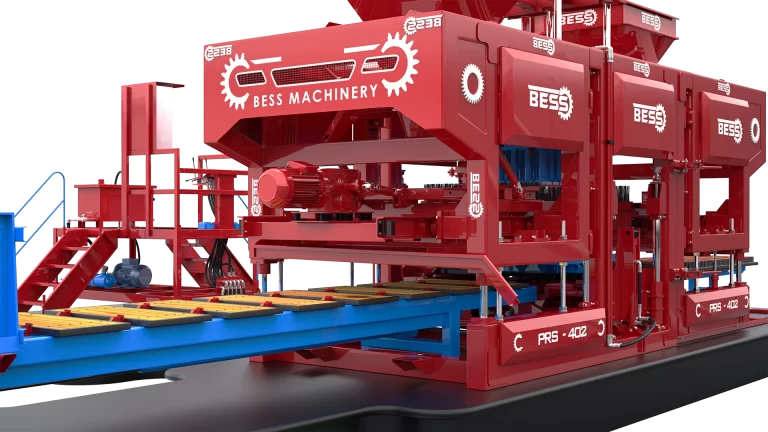

Consistent High Standards with Every Press

- Automatic and adjustable vibration time

- Automatic mold filling and shaking grid – 2.2 kW motor

- Adjustable pressure for hydraulic press – 11 kW hydraulic motor

- Smooth surface ensured with top vibration (0.28 kW x 2 units)

05

Upper Mold System with 5-Year Replacement Guarantee

- ø60mm shaft at 6 points to prevent upper mold flex

- Maintenance-free SFERO bearing system

- Special chrome-plated shafts

- Product height adjustment system

06

Adjustable Pallet System Compatible with Different Pallet Dimensions

- Claw-type pallet pulling system

- Standard production even with variable pallet sizes

- Adjustable pallet feeding system

- Production pallet size: 50×115 cm

07

Ergonomic Pallet Transport Trolley

- Compatible with 50×115 cm pallets

- Quick and easy pallet transport

- Designed to prevent product damage

- Effortless operation with sliding bearings

08

Hydraulic System that Prevents Operator Mistakes

- Special speed control valves

- Special brake system for pistons

- bottom mold equipped with pressure adjustment system

- pressure adjustment system for Upper mold press

- Hydraulic pressure: 40-200 bar

09

Maximum Performance in All Weather Conditions

- Hydraulic cooling system: 150 liters

- Hydraulic heating system: 200 liters

- Large capacity 200-liter hydraulic tank

- Easily replaceable external hydraulic filter

- Easy maintenance without opening the hydraulic unit

10

Easy-to-Use Electrical Panel

- Digital display with visual aids

- Compliant with European standards

- Siemens, Schneider, and ABB electrical components

- Total machine power: 29 kW

- Electrical system equipped with motor protection units

- Emergency stop system

11

Shaping Your Ideas with Steel Molds

- Monoblock CK45 body for paving molds

- St52-3 and Hardox 450 steel options for curbstone molds

- St52-3 and Hardox 450 steel options for hollow block and Asmolen molds

- Durable and long-lasting molds with special cutting and heat treatments

12

Quick and Reliable Mold Replacement

- Roller table designed to support mold loads

- Ability to change molds quickly

- Easy and fast mold replacement with compression method

Technical Specifications

Unlimited Creativity in Production!

With the PRS 402 semi-automatic paving block machine, you can produce over 600 concrete block models including all kinds of face mix paving blocks, curbstones, rain gutters, hollow blocks, solid blocks, hollow floor blocks (Asmolen), etc., ranging from 5 cm to 35 cm in height. Meet the needs of different sectors and highlight your products with creative designs. Explore the detailed production capacity of the PRS 402 machine.

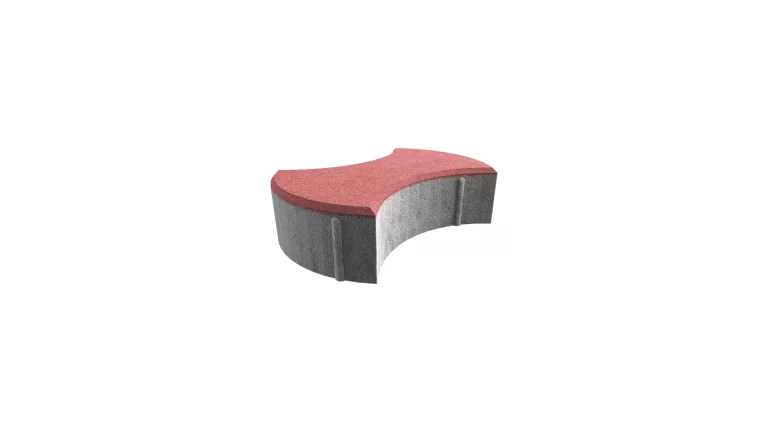

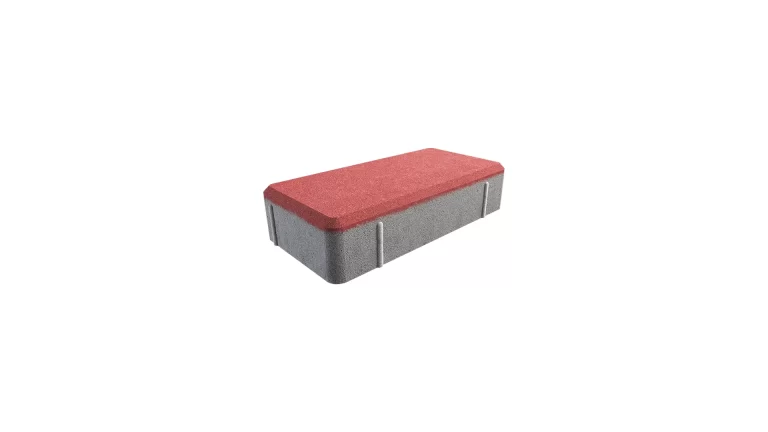

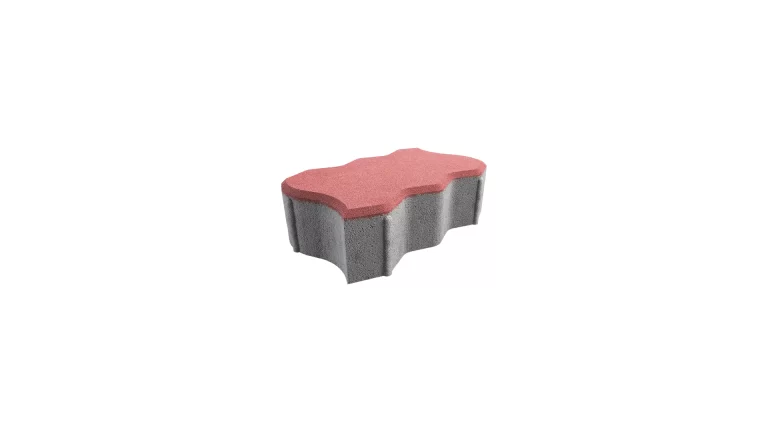

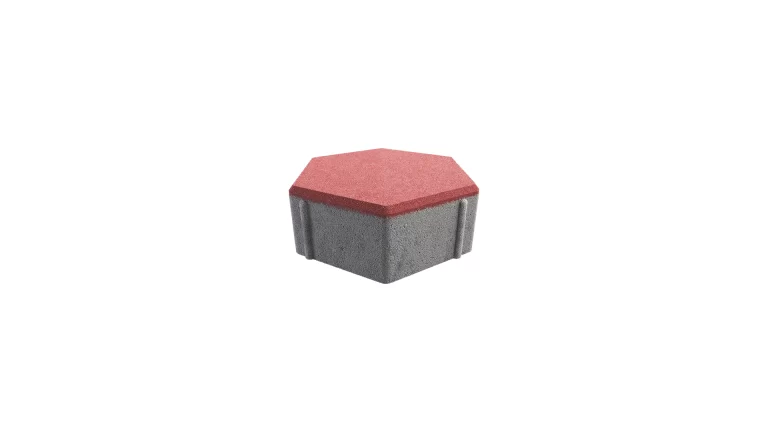

Popular Paving Blocks

163x197 mm

- Products On Pallet : 12 Pieces

- Capacity : 332 m² / 8 Hours

153x224 mm

- Products On Pallet : 8 Pieces

- Capacity : 275 m² / 8 Hours

98x198 mm

- Products On Pallet : 18 Pieces

- Capacity : 352 m² / 8 Hours

128x238 mm

- Products On Pallet : 12 Pieces

- Capacity : 364 m² / 8 Hours

200x228 mm

- Products On Pallet : 8 Pieces

- Capacity : 362 m² / 8 Hours

400x600 mm

- Products On Pallet : 1 Pieces

- Capacity : 240 m² / 8 Hours

Popular Concrete Blocks

100x400x200 mm

- Products On Pallet : 8 Pieces

- Capacity : 8.000 Pcs / 8 Hours

150x400x200 mm

- Products On Pallet : 6 Pieces

- Capacity : 6.000 Pcs / 8 Hours

200x400x200 mm

- Products On Pallet : 4 Pieces

- Capacity : 4.000 Pcs / 8 Hours

300x400x200 mm

- Products On Pallet : 3 Pieces

- Capacity : 3.000 Pcs / 8 Hours

Popular Hollow Floor Blocks (Asmolen)

150x500x200 mm

- Products On Pallet : 4 Pieces

- Capacity : 4.000 Pcs / 8 Hours

120x520x200 mm

- Products On Pallet : 6 Pieces

- Capacity : 6.000 Pcs / 8 Hours

80x520x200 mm

- Products On Pallet : 8 Pieces

- Capacity : 8.000 Pcs / 8 Hours

160x520x200 mm

- Products On Pallet : 4 Pieces

- Capacity : 4.000 Pcs / 8 Hours

150x550x200 mm

- Products On Pallet : 2 Pieces

- Capacity : 2.000 Pcs / 8 Hours

Popular Curbstones & Rain Gutters

95x500x200 mm

- Products On Pallet : 4 Pieces

- Capacity : 4.000 Pcs / 8 Hours

150x500x300 mm

- Products On Pallet : 2 Pieces

- Capacity : 2.000 Pcs / 8 Hours

150x700x300 mm

- Products On Pallet : 1 Pieces

- Capacity : 1.000 Pcs / 8 Hours

355x300x220 mm

- Products On Pallet : 4 Pieces

- Capacity : 4.000 Pcs / 8 Hours

400x260x120 mm

- Products On Pallet : 6 Pieces

- Capacity : 6.000 Pcs / 8 Hours

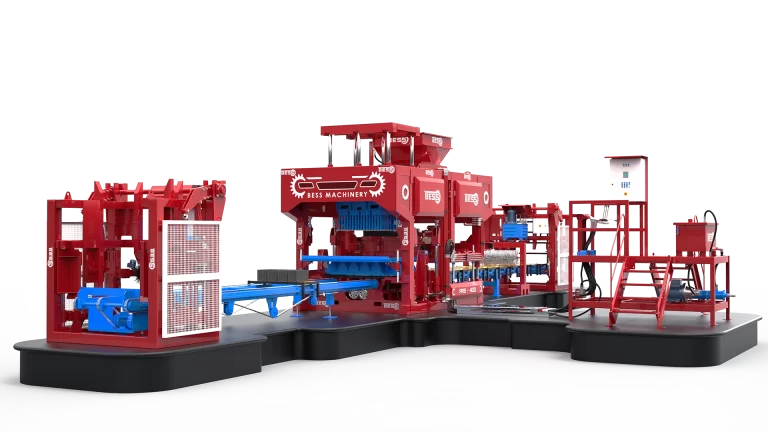

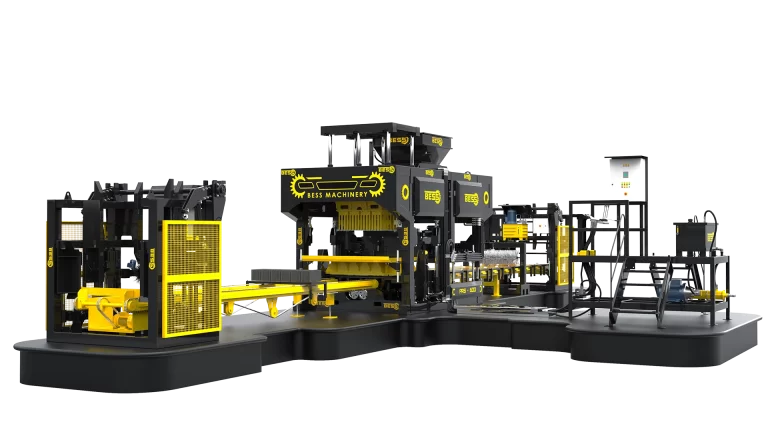

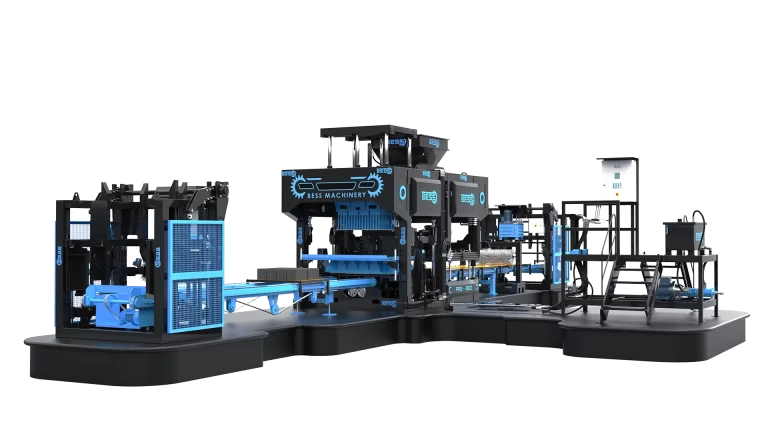

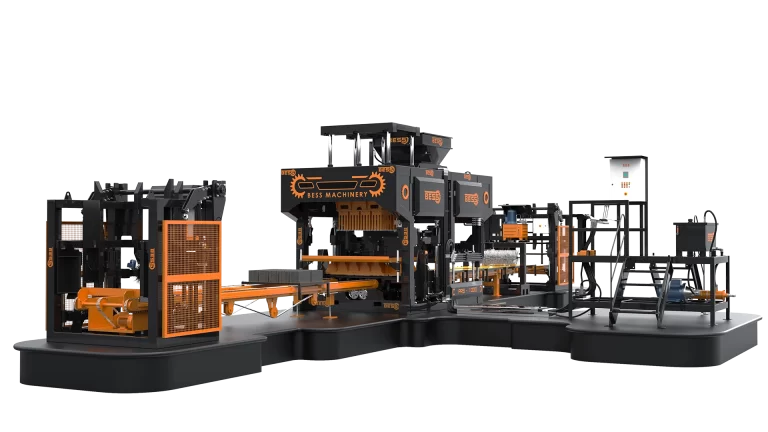

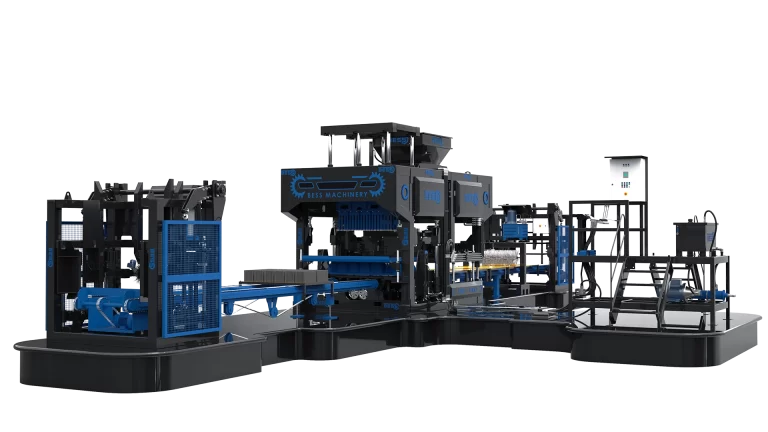

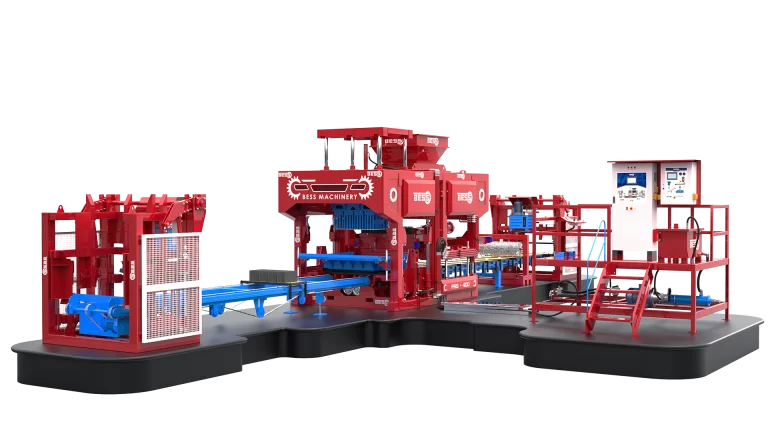

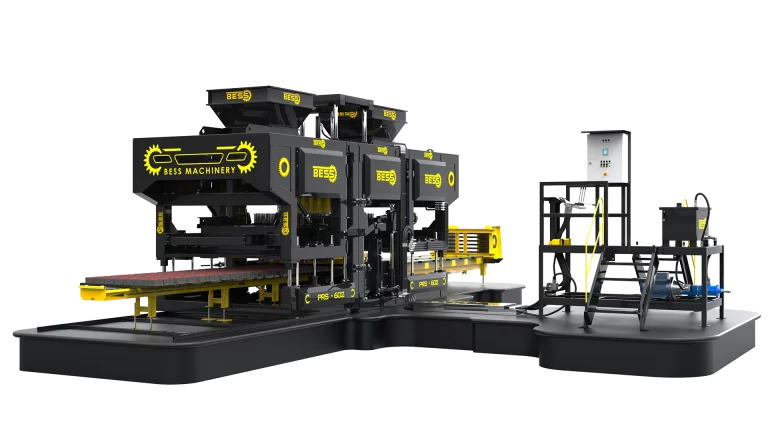

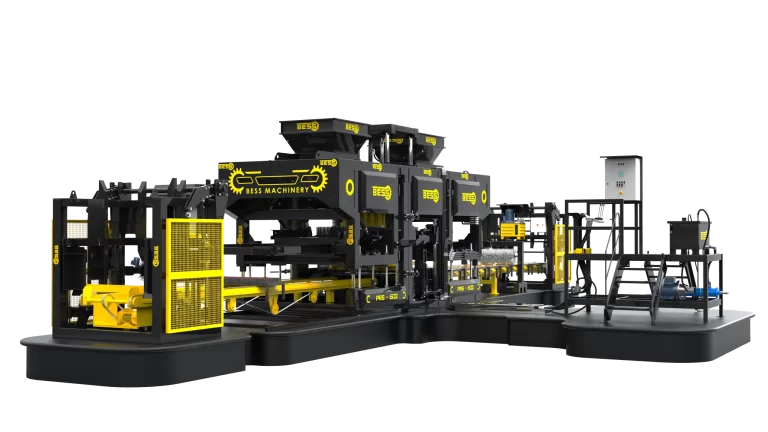

Installation Layout

You can click on the numbered items in the sample installation layout to review the specifications of the PRS 402 semi-automatic paving block machine equipment. You can customize your setup by adding or removing desired products. Please note that the provided installation layout example may vary based on your selected equipment and the land.

Other Capacities

BESS™ Frequently Asked Questions (FAQ)

The recommended installation and production area for the PRS 402 semi-automatic paving block machine is 2,000 m². Go to installation details.

A total of 7 personnel are required for the efficient operation of a semi-automatic plant: 1 machine operator, 1 mixer operator, 3 pallet transport staff, 1 pallet loading staff, and 1 raw material loading staff. Go to operational details.

Yes, vibrating machines, especially paving block machines, can experience fractures and cracks in their frames due to the vibration and pressing systems they operate with. These machines undergo high levels of stress on their chassis. However, we minimize the impact of vibration on the frame by using special reinforcements and damping wedges in our machines. This ensures robust and long-lasting solutions for our users. Go to reinforced Special Design chassis.

The vibration system is essential for paving block machines and is the most important factor affecting product quality. The most important features in vibration systems are easy installation and use, access to spare parts and service, and durability and reliability. For quality production and high performance, it is essential to consider these factors in the vibration system. Go to modular vibration system

The pallet dimensions for the PRS 402 are 50×115 cm, and they can be made from plastic, wood, or metal. In semi-automatic systems, the products are transported to the curing area using pallet carrying trolleys. Go to Pallet System

The most important factors affecting the performance of the machine’s hydraulic system are the quality and viscosity of the hydraulic oil, operating temperature, oil cleanliness and proper filtration, correct pressure and flow settings, high-quality components, proper installation, and regular maintenance. Each of these factors ensures the system operates efficiently and reliably. Go to Hydraulic System