BESS™ FREQUENTLY ASKED QUESTIONS

To produce one hollow block with the dimensions of 20x40x20cm, you will require approximately 1 kg to 1.2 kg of cement. The specific amount may vary depending on various factors, but this range is considered standard.

With a 50kg cement bag, you can produce approximately 42 hollow blocks, each measuring 20x40x20cm. The cement requirement per block ranges from 1kg to 1.2kg, and the actual quantity may vary depending on factors such as raw material quality and block size. Nevertheless, this is considered a standard estimation.

To produce one 20x40x20cm hollow block, approximately 0.8 liters (800ml) of water is added to the mixture. This estimate is based on using standard quality raw materials and cement.

To produce one standard hollow block measuring 20x40x20cm, approximately 18.8 kg of raw materials (such as stone dust and sand) and 1.2 kg of cement are needed. After drying, the block weighs around 20 kg. It’s essential to note that the percentage of raw materials may vary significantly if different materials like pumice or fly ash are used.

To produce one hollow block or other types of concrete blocks, three basic materials are required: cement, water, and sand. Optional additives can be incorporated to impart special characteristics such as improved insulation or soundproofing. These optional materials may include fly ash, pumice, silica fume, ground granulated blast furnace slag (GGBS), concrete accelerators, concrete retarders, and more.

To produce hollow blocks from pumice, a different recipe is required compared to the standard raw material recipe. The amount of cement used is increased to 12%, and the mortar requires additional water (approximately 1 liter per block). Additionally, to enhance the adhesive power, fine sand is sometimes used.

The standard weight of a 20x40x20cm hollow block is approximately 20kg when using normal raw materials. However, if fly ash or pumice is used, the weight of the block can be reduced by up to 8kg, resulting in a block weighing around 12kg to 15kg.

The raw material size suitable for producing hollow blocks and solid blocks is 0-7mm mixed with stone dust. The important consideration is that the maximum size of the raw material should not exceed 7mm.

Pumice is a lightweight, porous volcanic rock that is formed when lava with a high content of gas and water is ejected from a volcano during an explosive eruption. The rapid cooling of the lava traps the gas bubbles inside, creating a highly vesicular and porous structure.

Pumice is usually light-colored, ranging from white, cream, and gray to light brown. It has a low density, which makes it float on water. The unique porous nature of pumice gives it excellent insulating properties and makes it an ideal material for various applications.

Due to its lightweight and abrasive properties, pumice is commonly used in:

- Construction: It is used as an aggregate in lightweight concrete blocks, lightweight concrete, and insulating concrete.

- Horticulture: Pumice is used as a soil amendment to improve drainage and aeration in gardening and horticulture.

- Cosmetics: It is used in beauty and skincare products as an exfoliating agent.

- Cleaning and Polishing: Pumice stones are used to clean and polish surfaces like metal, glass, and ceramics.

- Filtration: Pumice is used in water and air filtration due to its porous nature.

Pumice can be found in regions with active or dormant volcanic activity. It is typically associated with volcanic eruptions that produce frothy, gas-filled lava. Some common places to find pumice include:

- Volcanic regions: Pumice is often found near or around volcanoes. Countries with active or recent volcanic activity are likely to have pumice deposits. Examples include regions in Iceland, Italy (e.g., Mount Vesuvius), Japan, New Zealand, the United States (e.g., in the Pacific Northwest), and many other volcanic island chains.

- Ancient volcanic areas: Pumice deposits can also be found in areas that have experienced volcanic activity in the past. Over time, pumice deposits may be buried under other sediments and become part of the geological formations.

- Coastal regions: Pumice rocks, especially smaller pieces, can be transported by ocean currents and washed up on coastal shores after being ejected from volcanic eruptions and carried by water.

- Quarrying sites: Some countries or regions have established quarries to mine and extract pumice for commercial use. These quarries can be found in volcanic areas with significant pumice deposits.

Several countries around the world have significant pumice resources due to their volcanic activity. Some of the countries with the most substantial pumice deposits include:

Italy, Greece, Turkey, Iceland, Japan, United States, New Zealand, Indonesia, Chile, Mexico, Philippines, Russia, Ethiopia, Kenya, Tanzania, Rwanda, Democratic Republic of Congo, Cameroon, Papua New Guinea, Vanuatu, Solomon Islands, Tonga, Fiji, Ecuador, and Peru

Fly ash is a fine, powdery byproduct produced from burning pulverized coal in power plants. It contains mineral particles and chemical compounds from the coal combustion. Due to its pozzolanic properties, fly ash is widely used as a supplementary cementitious material in concrete. It improves concrete’s workability, durability, and long-term strength while reducing the need for Portland cement, making construction more sustainable. Additionally, fly ash finds applications in soil stabilization, road construction, and waste stabilization, contributing to environmentally-friendly practices.

The use of fly ash in producing construction blocks not only makes the blocks more environmentally friendly by reducing the need for cement, but it also improves their strength, durability, and insulation properties. It is an excellent example of sustainable and eco-friendly construction practices, as it utilizes a waste product to create valuable building materials.

several countries are significant producers of fly ash due to their high reliance on coal-fired power plants and industrial processes. The countries with the most fly ash generation include:

China, India, United States, Russia, Japan, Germany, South Africa, Indonesia, Poland, Australia, Brazil, South Korea, Ukraine, Turkey, Mexico, Vietnam, Egypt, Czech Republic, Philippines, and Thailand

- will be fewer rows so total mortar usage will drop to minimum.

- Due to their lighter weight.

- Because of their larger size, facilitating easier installation.

- One side being closed prevents mortar from entering the cavities while placing upper layers.

- Their increased height results in fewer rows required, minimizing overall mortar usage.”

The thickness of cement or mortar between blocks, often referred to as “joint thickness” or “mortar joint,” can vary depending on the type of construction and the specific blocks being used. Here are some general guidelines for common block sizes:

- Standard Concrete Blocks (CMU – Concrete Masonry Units):

- For regular masonry walls: A common joint thickness is about 3/8 inch (9.5 mm) to 1/2 inch (12.7 mm).

- For load-bearing walls or walls requiring higher strength: A thicker joint of around 1/2 inch (12.7 mm) to 5/8 inch (15.9 mm) might be used.

- Clay Hollow Blocks:

- Clay blocks often have a similar joint thickness to concrete blocks, ranging from 3/8 inch (9.5 mm) to 1/2 inch (12.7 mm).

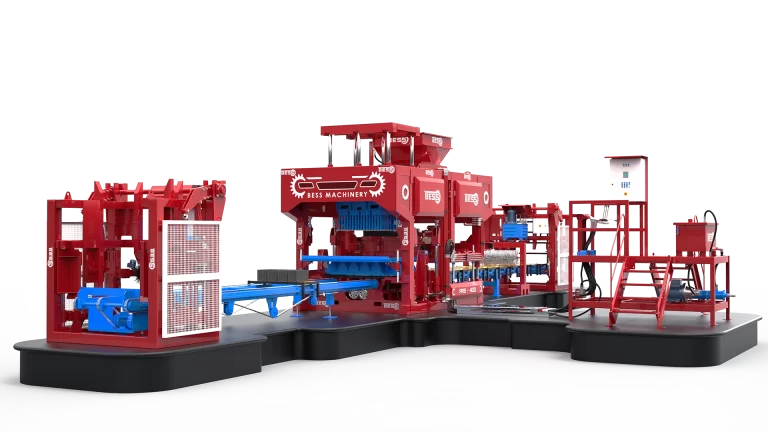

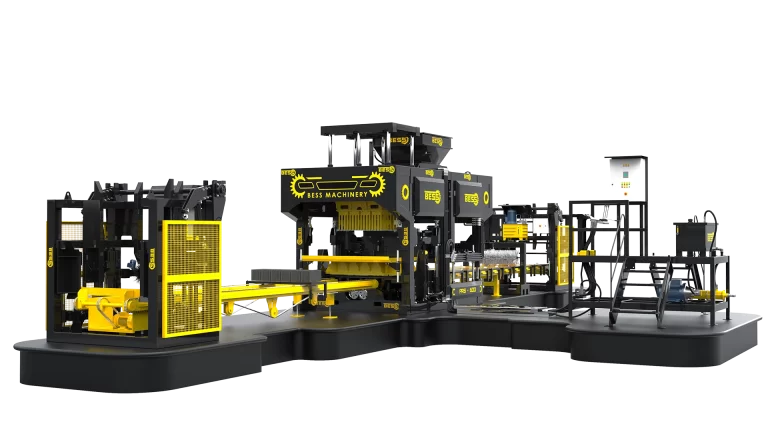

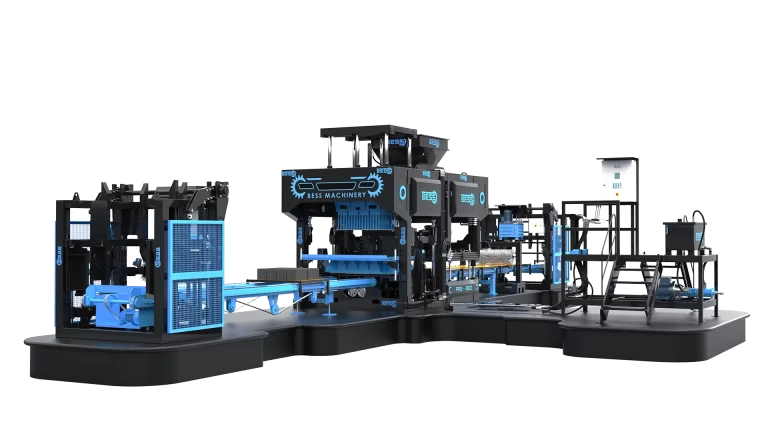

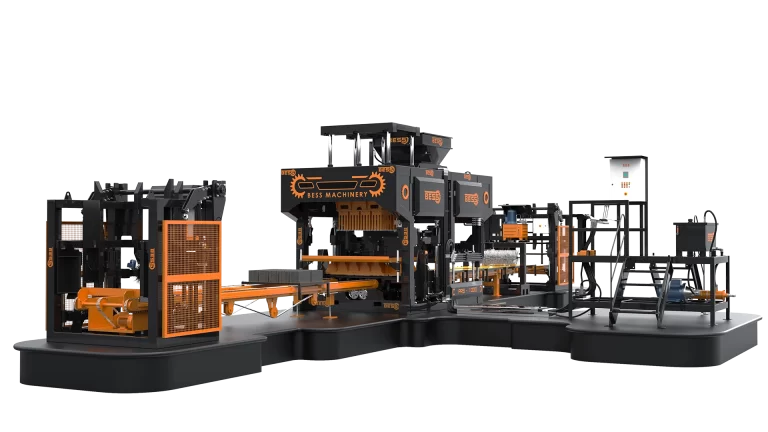

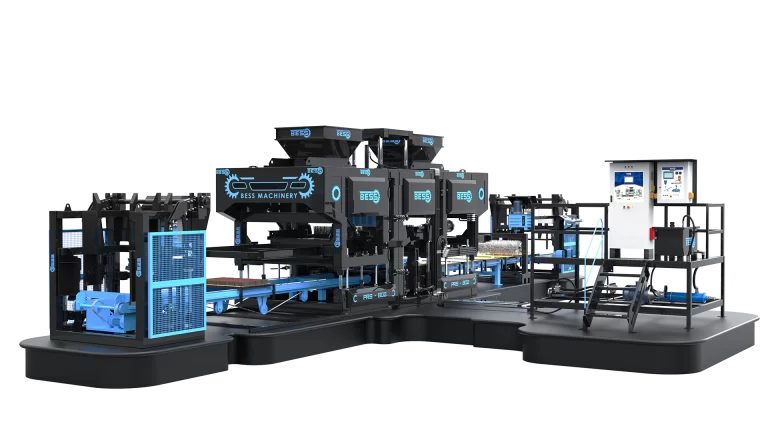

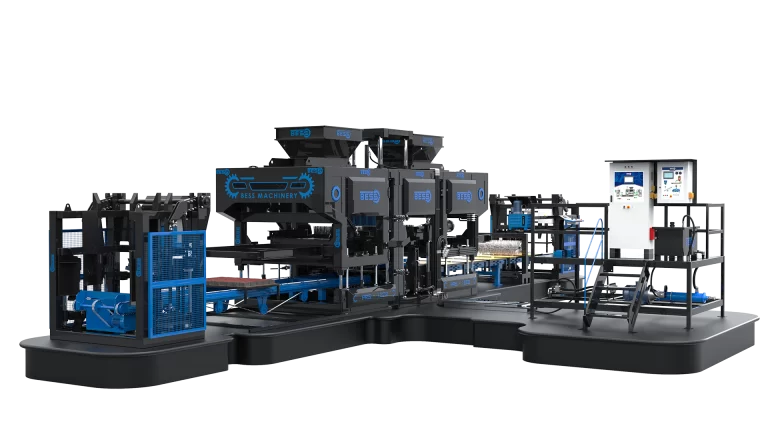

Starting a hollow block making business can be profitable if there’s demand for construction materials in your area, and you focus on quality, innovation, and cost-effective production. Ensure you understand regulations, have a solid marketing strategy, and are prepared for the initial investment and potential risks. Depending on these factors you need to choose the right machine as well.

The cost-effectiveness of producing your own concrete blocks varies based on the quantity required. Additionally, equipment is a requirement. As manual production lacks machinery, it can be labor-intensive and challenging. Moreover, creating your own blocks can be time-consuming. The final quality of the block is also different compared to automatic productions with machinery.

The time it takes for cement blocks to cure varies due to weather conditions and temperature. Post-production, a crucial step is splashing water on the blocks every 4 hours to facilitate the curing process. In sunny weather at around 20 degrees Celsius, the blocks can be fully cured and ready for collection from the pallets within approximately 24 hours.

Solid concrete blocks have various applications in construction due to their durability, strength, and versatility. Some common uses of solid concrete blocks include:

Load-Bearing Walls: Solid concrete blocks are often used to construct load-bearing walls in buildings. Their strength and stability make them suitable for supporting structural loads.

Foundations: Solid concrete blocks can be employed in foundation walls, providing a sturdy base for the entire structure.

Retaining Walls: These blocks are used to create retaining walls that hold back soil and prevent erosion in landscaping projects.

Exterior Walls: In some cases, solid concrete blocks are used for exterior walls, providing insulation and security.

Basement Walls: These blocks are commonly used to construct walls in basements due to their resistance to moisture and stability.

Firewalls: Their fire-resistant properties make solid concrete blocks suitable for constructing firewalls in commercial and industrial buildings.

Soundproofing Walls: Solid concrete blocks can help reduce noise transmission, making them valuable for soundproofing applications.

Cold Storage Rooms: Due to their insulation properties, solid concrete blocks are used in the construction of cold storage rooms.

Industrial Buildings: Solid concrete blocks are suitable for various industrial structures, including warehouses and factories.

Public Infrastructure: They are also used in the construction of public infrastructure like bridges, retaining walls along highways, and more.