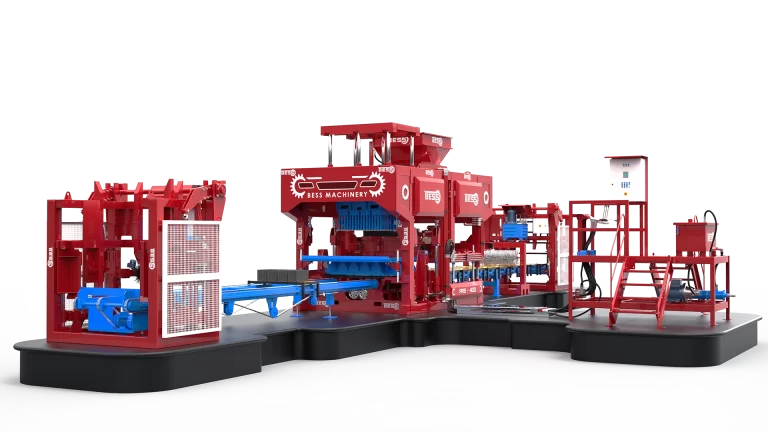

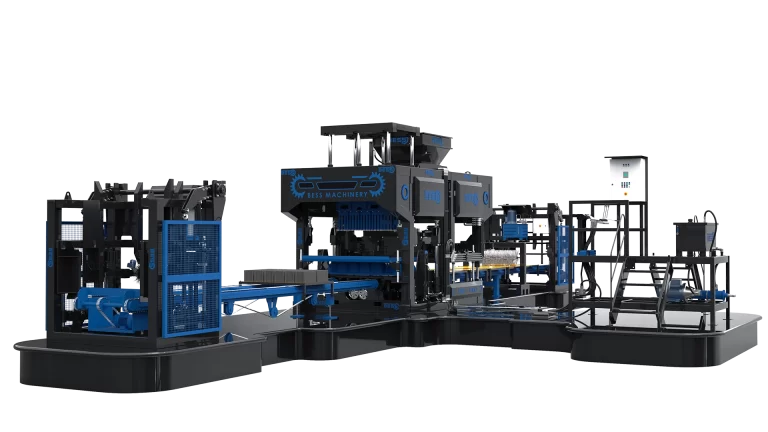

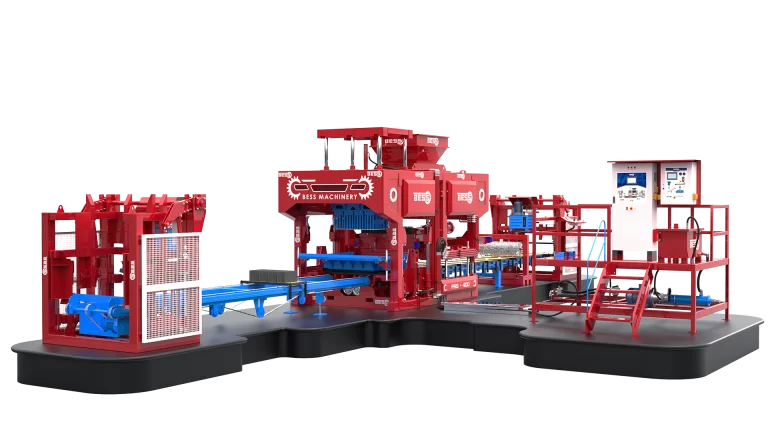

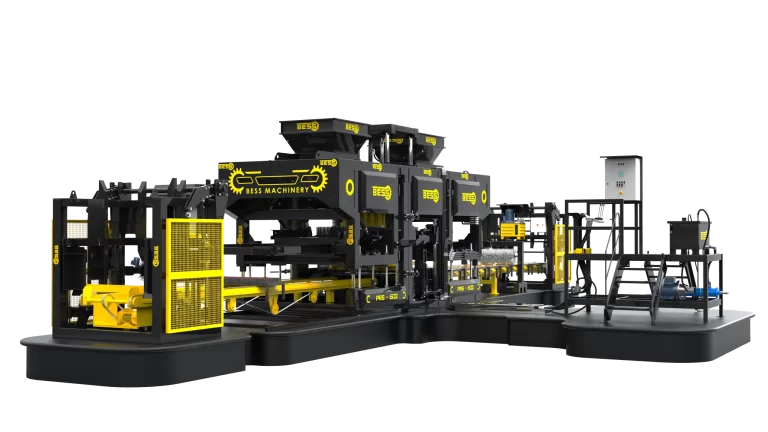

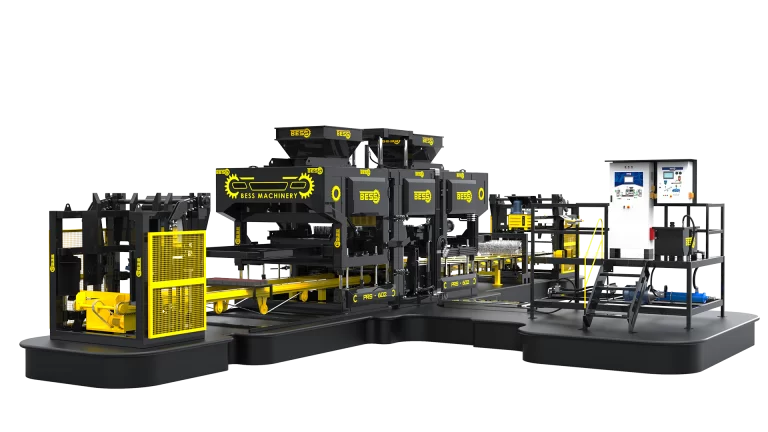

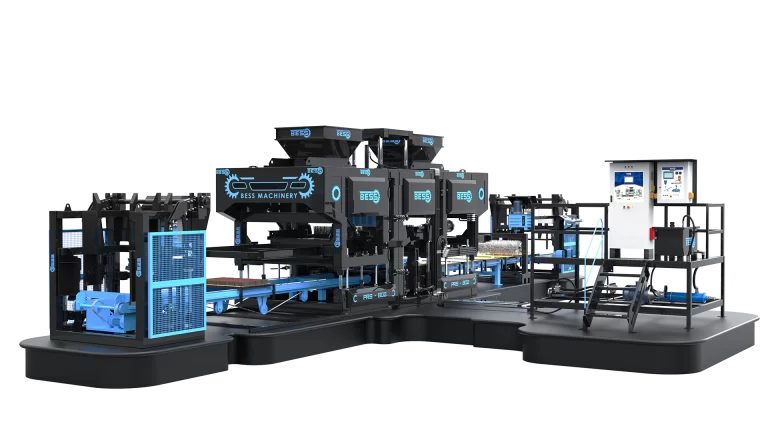

With over 680 machines installed across 62 countries, our concrete block making machines are known for reliability, durability, and performance in the markets. From big construction projects in Africa to fully automatic systems in Europe, businesses around the world continue to choose our machines for their flexibility, high production capacity, and long-term value.

Let’s take a closer look at how our machines are being used across different regions and why they continue to be the trusted choice for concrete block production globally.

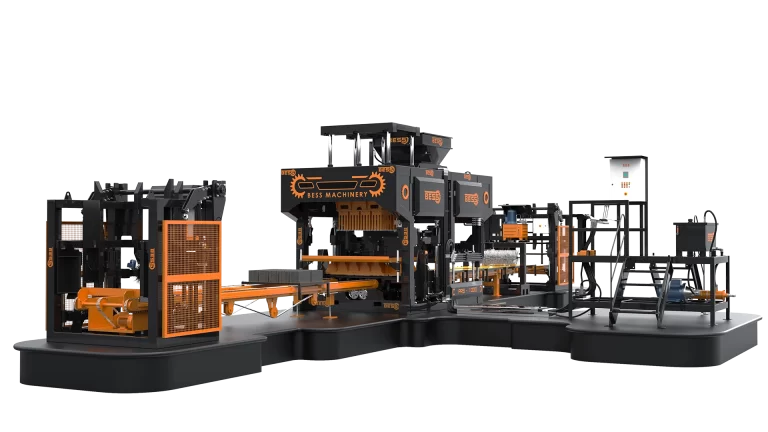

We have installed our concrete block machines in more than 20 African countries. Our machines are used to produce concrete blocks, paving blocks, and curbstones for housing projects, roads, and government works. African companies trust our machines because they are easy to use and work well in extreme conditions.

In North Africa, our machines are working in countries like Morocco, Algeria, Libya, and Egypt. These machines help our customers produce high-quality concrete products every day. Thanks to their strong and simple design, they require very little maintenance and can run for many years.

In West Africa, we have machines operating in Ghana, Nigeria, Senegal, Ivory Coast, Gambia, Benin, and Burkina Faso. Customers in these countries use our machines to meet the growing demand for construction materials. With high capacity and low labor needs, they help reduce costs and increase profits.

In East and Central Africa, countries like Ethiopia, Kenya, Mozambique, Congo, and Zimbabwe rely on our machines in both cities and remote areas. Whether it’s a hot climate or a heavy workload, our machines continue to perform with no problems, making them a smart investment for any business.

Most of the project done in africa are semi-automatic machines. there are a few reasons for this:

- Finding skilled labor is difficult in Africa

- Finding spare parts is challenging in Africa

- Providing technical service is a problem in Africa

- The electrical grid is not very reliable and accurate in Africa

- Operators are careless most of the times

- Troubleshooting should be easy and understandable.

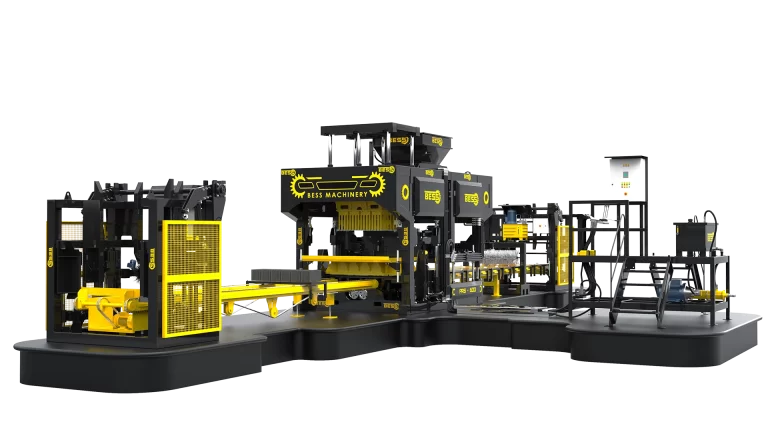

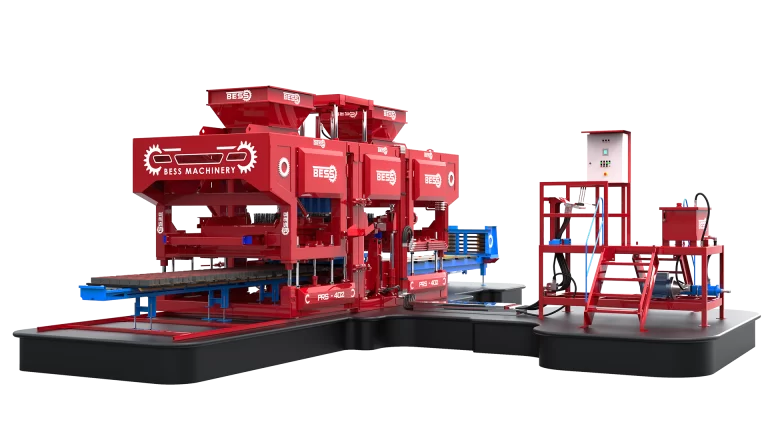

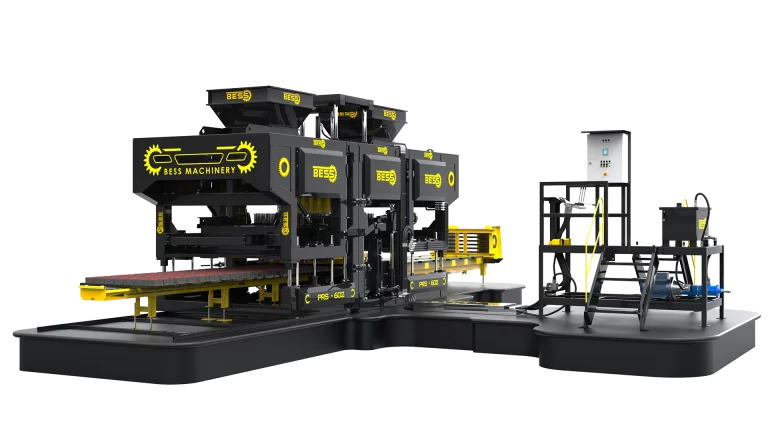

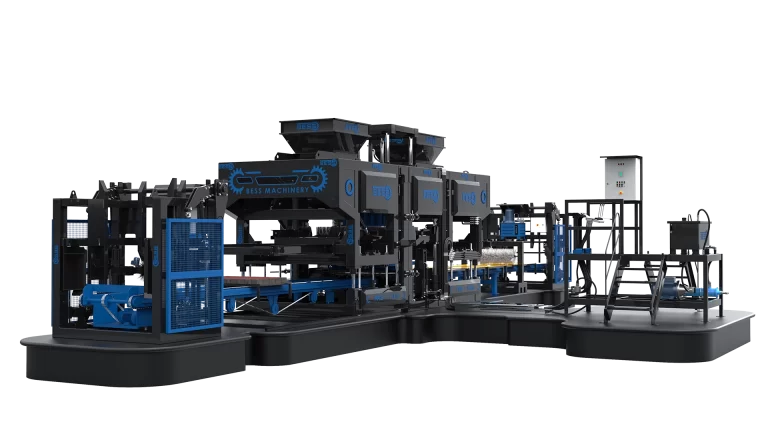

In Europe, many companies focus on strong machines that last for many years. Our block making machines are designed to meet this demand. They are easy to use, durable, and meet European quality standards.

We have installed machines in Romania, Hungary, Portugal, Ireland, and France. These machines help businesses produce different types of blocks, paving stones, and curbstones. They are used in both small workshops and fully automatic factories.

One of our biggest markets in Europe is Georgia. We have installed more than 200 machines there.

Because labor is expensive in many European countries, customers prefer fully automatic systems. Our machines help reduce labor costs while increasing daily production, making them a smart choice for long-term investment.

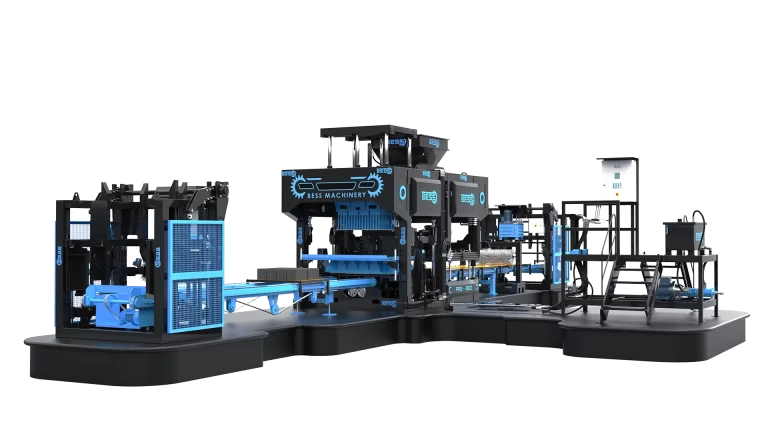

Asia includes many different climates, markets, and project sizes. Our concrete block machines are designed to work efficiently in all kinds of conditions, from hot deserts to cold regions.

We have installed machines in Iraq, Syria, Kuwait, the UAE, Jordan, Lebanon, Oman, Turkiye and Yemen. These countries often face high temperatures and dusty environments. Our machines work smoothly in these areas thanks to their smart cooling system design.

In Central Asia and the Caucasus region, countries like Kazakhstan, Azerbaijan, and Armenia use our machines for both small and large-scale production. Our machines are easy to set up and can be customized to fit different production needs.

Whether it’s hollow blocks, paving stones, or curbstones, our machines help companies in Asia produce high-quality products with low labor and energy costs. This makes them a smart investment for growing businesses.

In the Americas, customers look for user-friendly machines supported by strong after-sales service. Our machines meet these needs by offering high production capacity with simple controls, easy troubleshooting, and fast technical support.

We have installed machines in several South American and Caribbean countries, including Belize, Guyana, Colombia, the Dominican Republic, and Uruguay. These machines are used for producing various block types needed in local construction projects.

Our customers in these regions often face challenges like high humidity, limited staff, or changing product demands. That’s why they appreciate our machines’ flexibility and low maintenance needs.

We also provide training, spare parts, and technical support in the local language when needed. This ensures that our machines continue to work efficiently for many years after installation.

With more than 680 machines installed in 62 countries, our brand is known for trust, quality, and strong performance. That is the reason that businesses around the world choose our machines for their production.

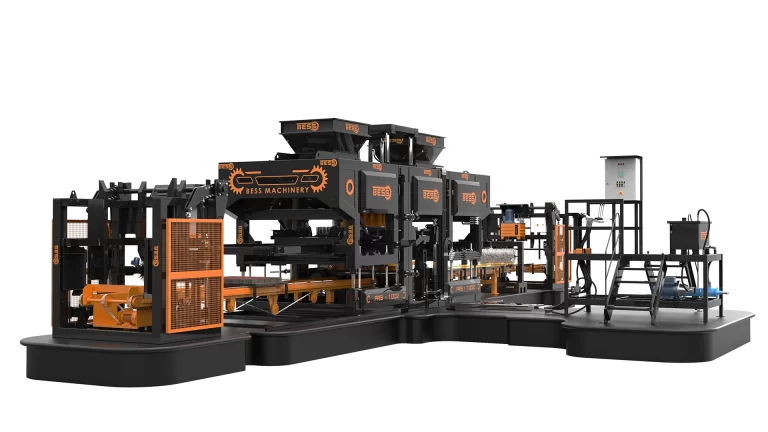

Our block making machines are designed to work in all types of environments—hot, cold, dry, or humid. Whether it’s a small project or a large factory, they help companies produce high volumes of concrete blocks every day.

Customers also prefer our machines because they can produce many types of blocks with just one machine. By changing molds, they can make hollow blocks, paving stones, curbstones, and more.

We also provide strong after-sales support, including installation, training, spare parts, and fast technical service. This complete support system makes our machines a smart investment for any business.