Ignoring Your Real Production Needs

To choose the right capacity block making machine, consider several factors, including the city’s population, ongoing and upcoming construction projects, and the current demand for blocks. Let’s explain it with an example. If you choose PRS1000, this machine will produce 10.000 to 20.000 blocks per shift. Let’s say your demand is only 6000 blocks daily. In such a case, you need to reduce the number of operation hours to be compatible with demand. Also, you need to pay the workers one full day to keep them. This will result in lower performance of your plant.

On the other hand, if the block making machine is too small compared to demand, you will have to increase the number of working hours to keep up with the demand. In this case, you need to pay extra money for the workers.

Choosing the right capacity machine will prevent many unwanted situations in future.

Choosing Cheap Over Reliable

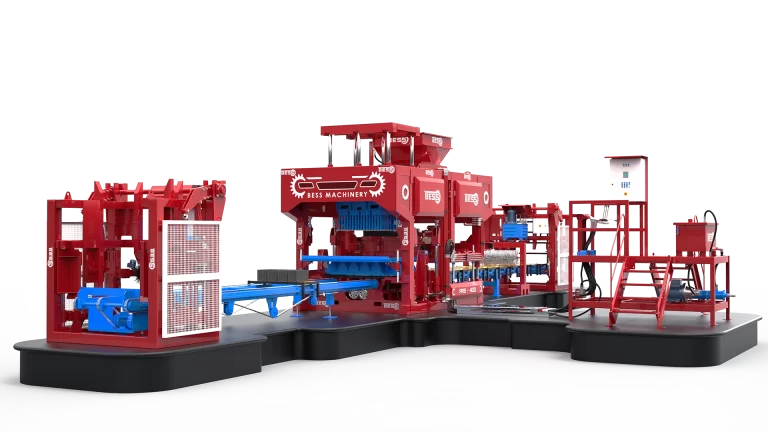

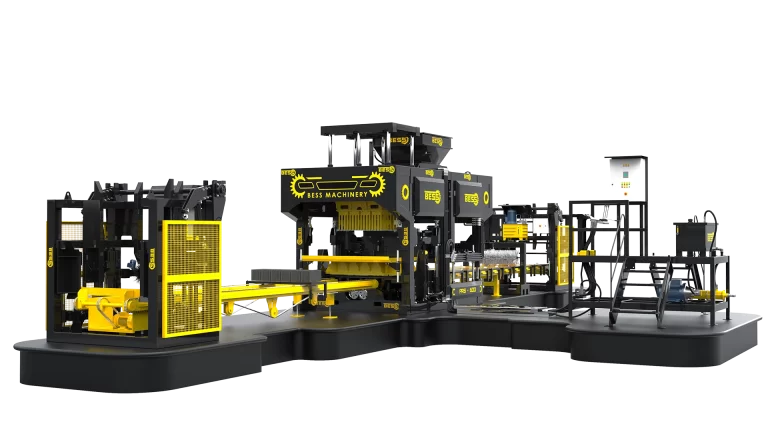

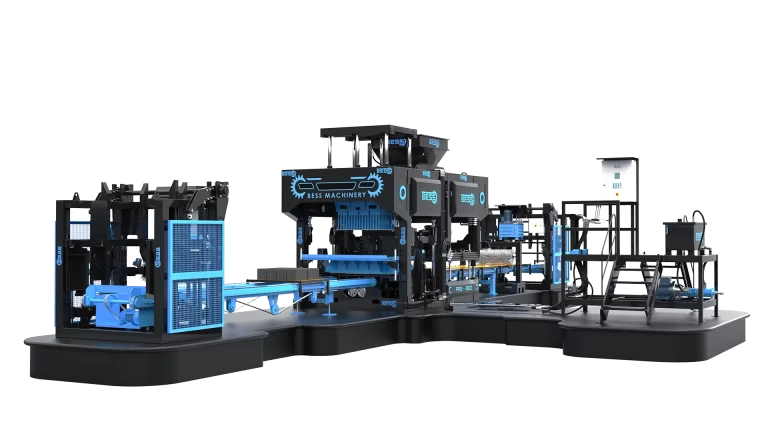

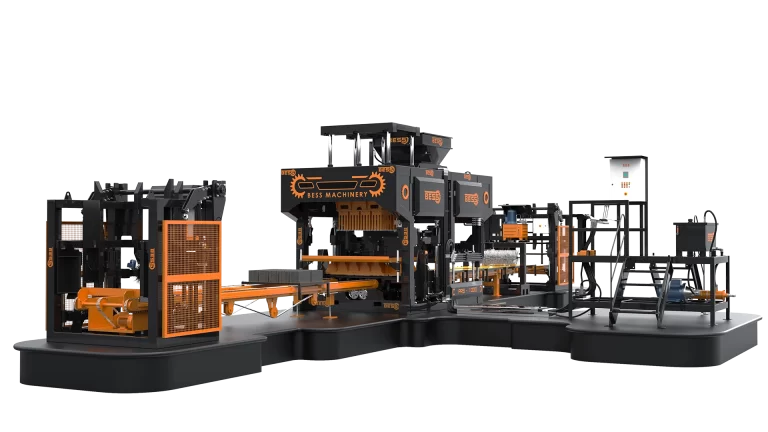

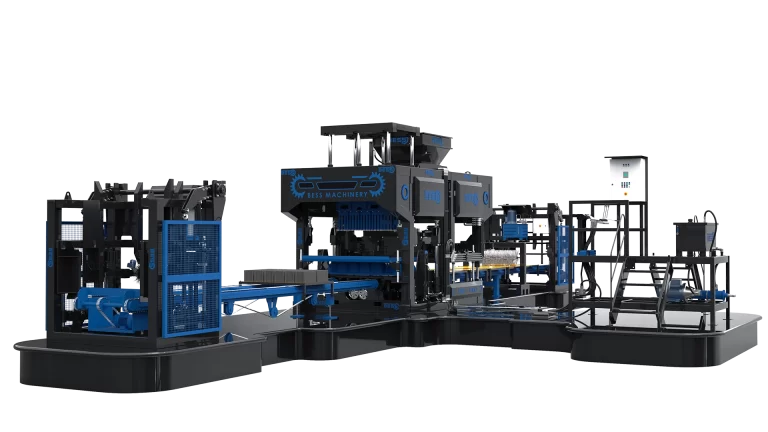

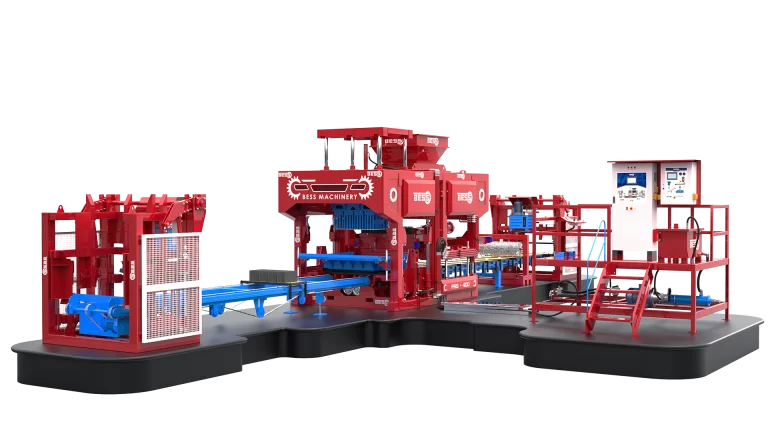

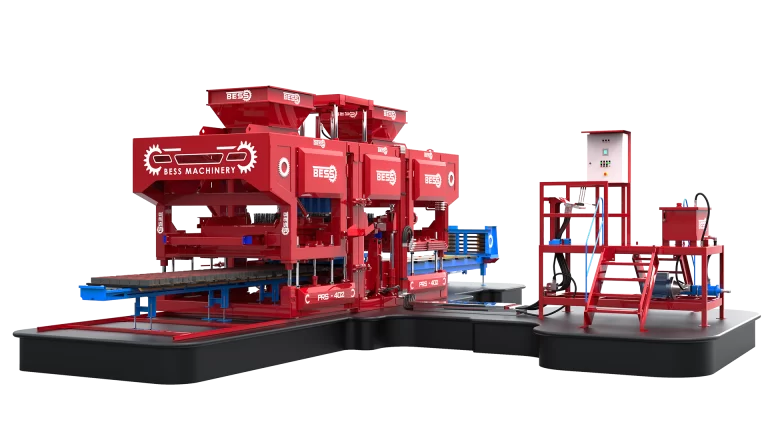

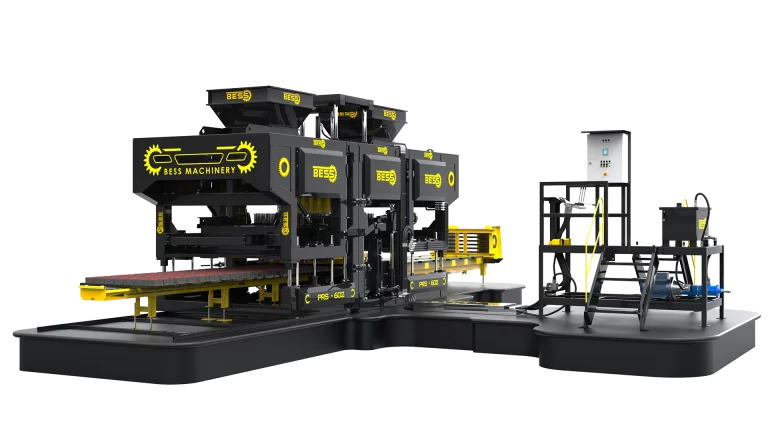

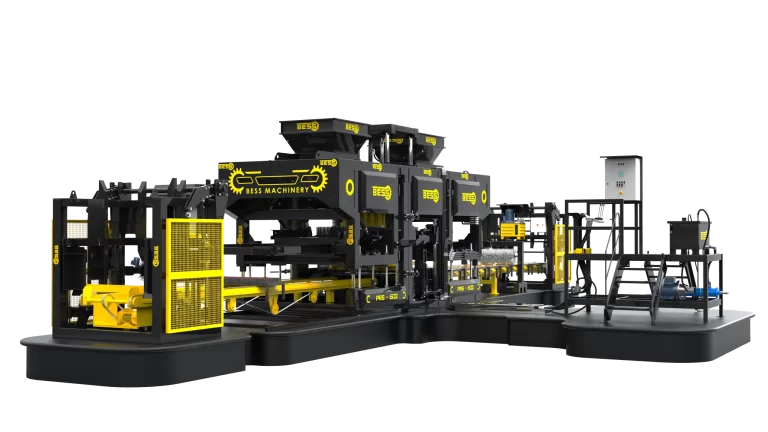

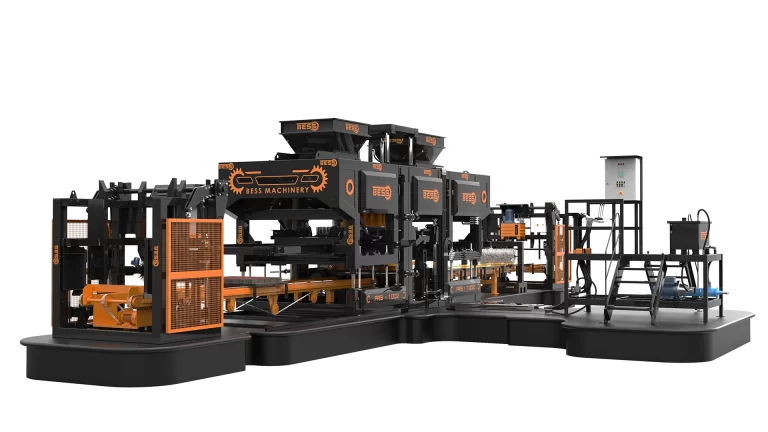

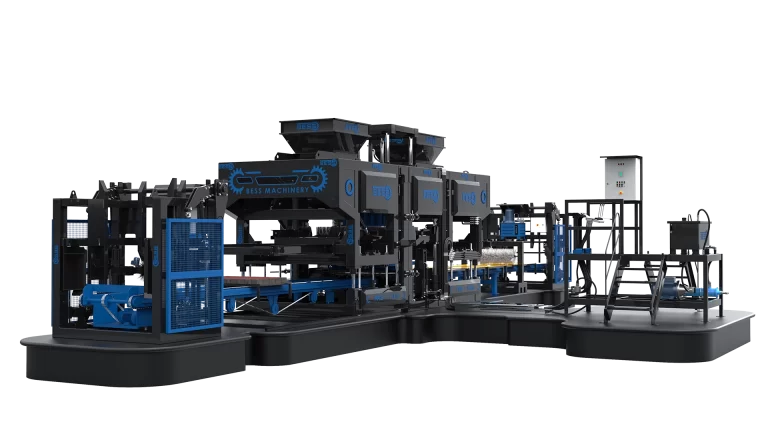

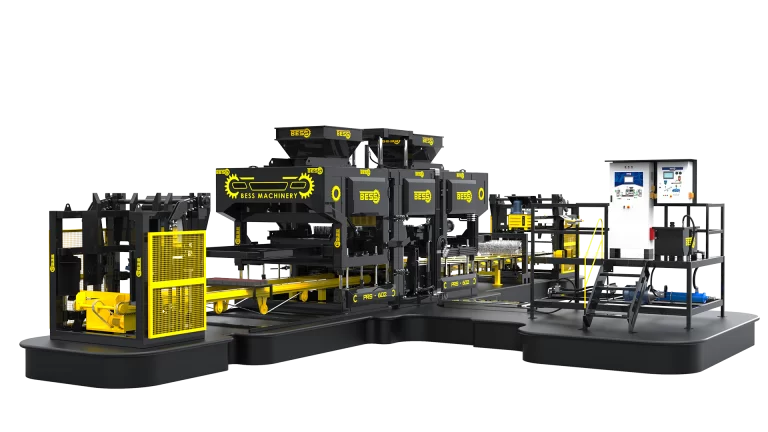

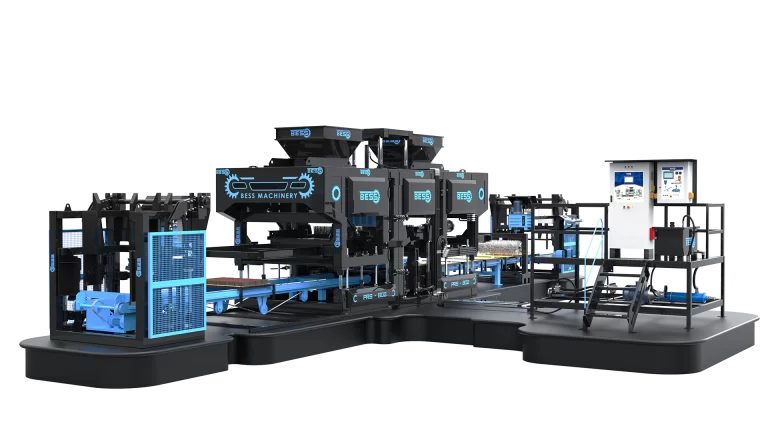

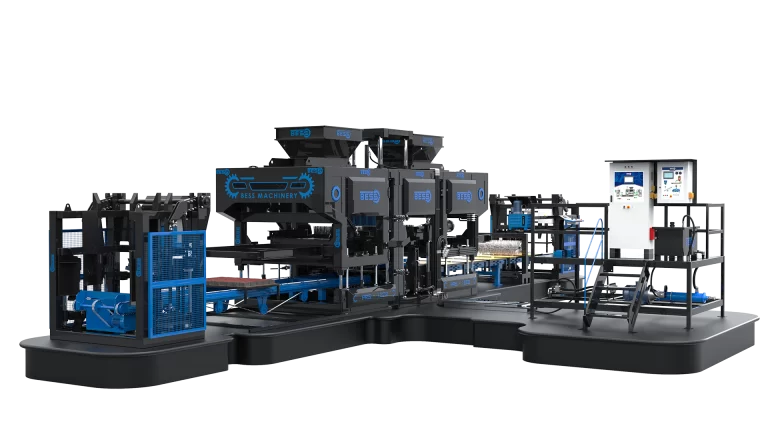

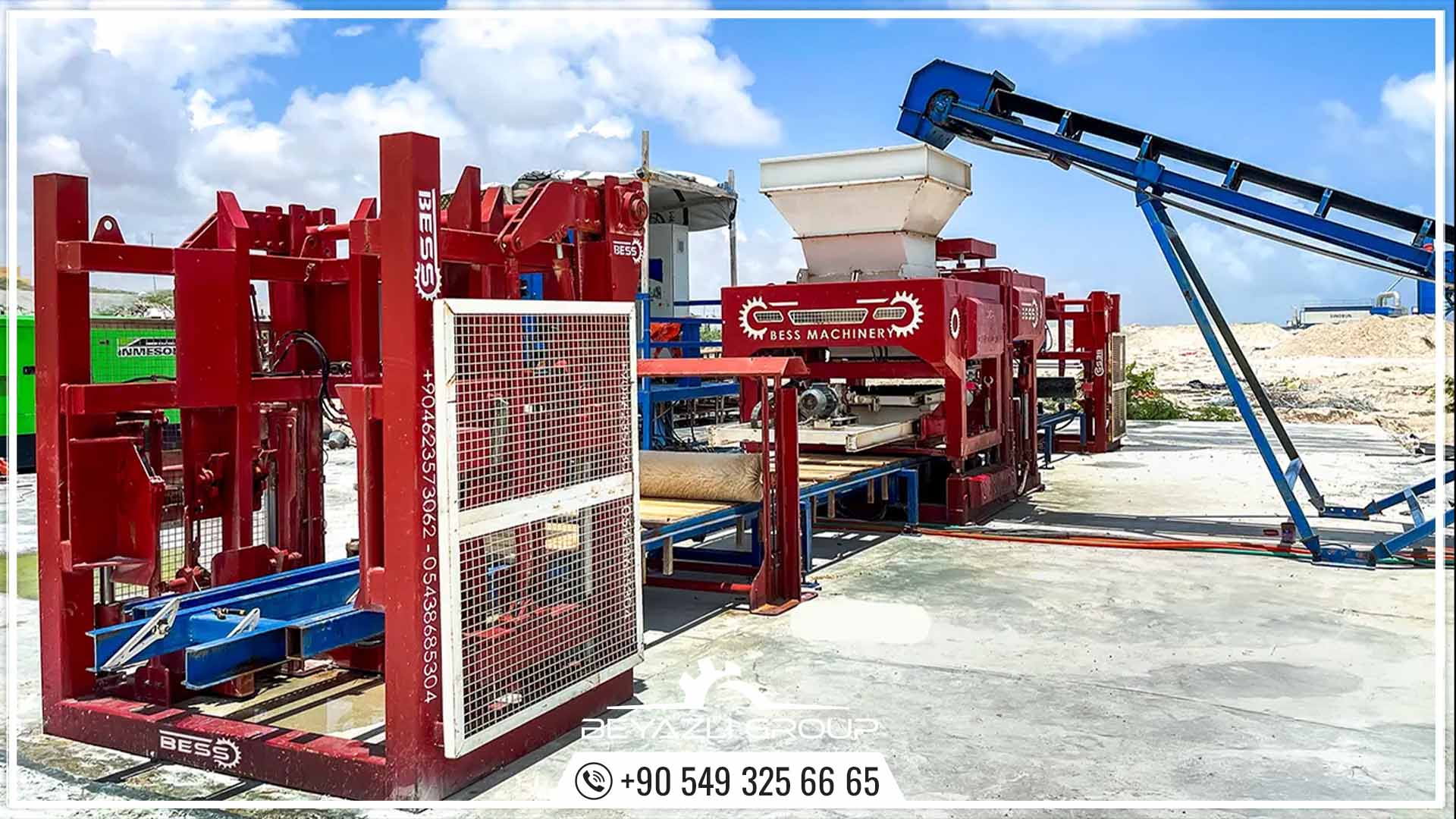

There are many different brands of block making machines with different prices in the market at the moment. Some of these machines only produce hollow and solid blocks while some of the produce all the shapes possible.

Most of the startups fall into the trap of choosing the cheapest machine. They think it will save them money, but it leads to higher costs over time.

Low-cost block making machines are often manufactured with low-quality and non-standard equipment. In the beginning, everything looks perfect, but after a while, the problems start. The problems are frequent breakdowns, difficult troubleshooting, lack of spare parts, and production time that is lost for the downtimes. The final result is missed deliveries, upset customers, and a lot of money spent on repairing the machine and getting it back to work.

To make sure a machine is reliable, you need to visit the production line of the machine and see how machines are made. You can check quality and thickness of the raw materials used on the machine. Also, you need to check the brands of the components installed on the machine. The European brands are the most trusted ones.

Not Checking After-Sales Support

One of the most critical aspects of buying a block making machine that is often neglected is after-sales support. What is going to happen after you buy the machine and pay the whole amount? The points that must be discussed before the sale are as below

- Installation and commissioning of the machine.

- Finding the best recipe and giving it to the client, since most of them don’t have enough experience with the raw material.

- Training the staff for proper use of the machine.

- Training the staff to do simple troubleshooting on the machine when something is wrong.

Not Considering Local Conditions

(Climate, Power Specs, Raw Material Availability)

Local conditions vary significantly from country to country, and even from city to city. Based on your local conditions, you need to choose the right type of machine. some of the factors are discussed below:

Climate:

Extreme weather conditions can affect the block making machine if no precautions are taken before purchasing. For example, humidity and heat cause failures in electrical networks without proper protection.

For extremely cold areas, you need proper heating for the hydraulic system.

For extra dusty areas like near stone quarries, the proper filtration should be included in the system as well.

power specifications :

Power specifications are different in some countries. some of them use 380V 50Hz 3 phase while some countries use 220V 60Hz 3 phase. Based on your power requirements, the suitable machine should be chosen.

The other factor is that the plant is powered by an electric grid or by a generator.

if there is an electrical grid available, you need to check the total power on your transformer and choose the machine based on that. If you are planning to use a generator, you need to choose the machine first and then choose the right generator based on the machine. Generators are mostly powered by diesel, and we call them diesel generators.

Raw material availability:

Raw materials have different specifications from city to city. The amount of water that will be added to the raw material and the amount of cement that is required will be different based on raw materials. The block making machine should be compatible with the raw material that is being used. To get more information about raw materials, please check suitable aggregate types for hollow block production.

Labor scales and availability:

Some machines require skilled labor, especially fully automatic machines.

If the machine is installed in areas with limited skilled labor and technical service, it’s best to choose a user-friendly semi-automatic machine.

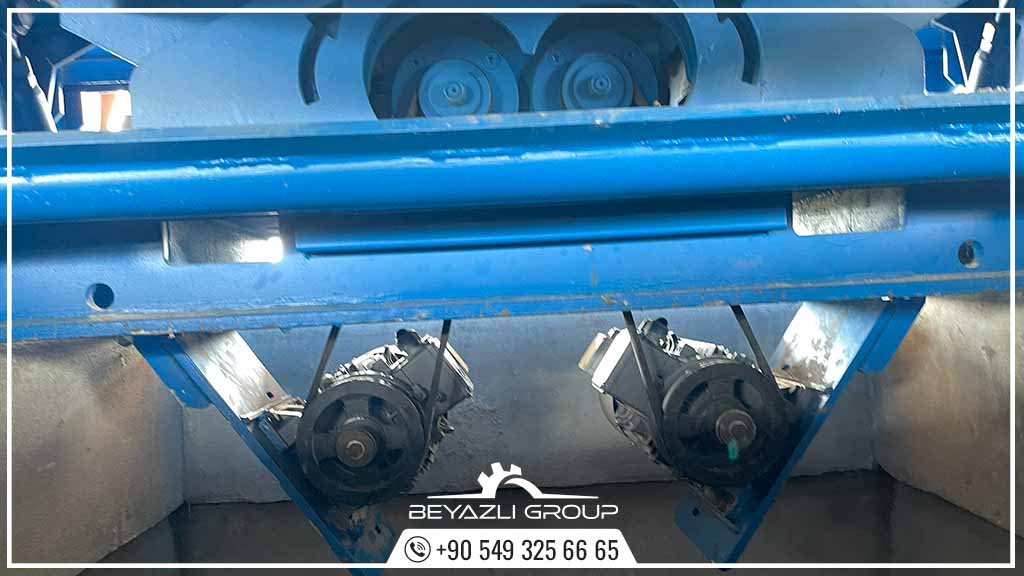

Neglecting Vibration System Technology

The vibration system is the heart of block making machines. It is very important to have a proper vibration table. Otherwise, it will impact the density, surface smoothness, and final strength of the block.

There are different systems for vibration tables. It should be inspected carefully to make sure what type of vibration system is used on the machine.

Weak vibration table impacts the final blocks directly. If your blocks are low quality without enough compaction, the edges are cracked and surfaces are uneven, and cycle time is increased. you need to look into your vibration table.

Vibration time and power should also be adjustable based on the production shape. The amount of vibration applied to a hollow block is different from a paving block.

There should also be an upper vibration system aside from the bottom vibration to result in better finishes in paving blocks.

Having a strong vibration table enables you to produce not only hollow blocks, but also solid blocks, paving blocks, curbstones, and many other different shapes. To learn more about the types of blocks that you can produce by our block making machines please read 10 different blocks produced by concrete block machines.

Failing to Plan for Installation Area and Layout

Buying the block making machine is only the first step to start the block production business.

you need a proper land to install your machine. The land should be big enough to have a production area, curing area, sales office, stock area for cured blocks, and room for staff.

the smallest land for small machines needs to be 1500m2.

The foundation beneath the machine should be prepared based on the machine. This design is given by the manufacturer.

The machine should be positioned correctly to have the best workflow with limited wasted area.