Similarities Between Semi-Automatic and Fully Automatic Block Making Machines

Before discussing the advantages of each system, let’s see what common features are between semi-automatic and fully automatic block making machines.

- First of all, both systems can produce hollow blocks, solid blocks, paving blocks, and curbstones by changing the mold. The product height for both models is 5cm to 35cm.

- Another common thing between two machines is that both machines have fully automatic mold filling system and a vibration system.

The advantage of this system is that the quality of the block is not related to the operator in both systems. You will have the same quality blocks all the time, and it doesn’t depend on the operator. - Vibration power is also the same on both the Bess semi-automatic and fully automatic block making machines.

- The main vibration core and chassis of the machine are the same in both models.

Semi-Automatic Block Making Machine Working System

As the name shows, an operator is required to operate the semi-automatic block making machines. The operator controls the main movements of the machine.

For the production of the blocks, you need to first load aggregate into the aggregate hopper. You can use either wheelbarrows or wheel loaders to load the aggregate hopper.

In semi-automatic machines, normally there is no weighing system for the aggregate, but one full hopper means one full mixer. The number of wheelbarrows unloaded into the hopper can be counted to get a roughly precise recipe for the concrete.

Water and cement are added to the mixer by the mixer operator. There is an option to add the cement to the mixer by cement silo too.

Using a cement silo depends on the facilities in the installation area too. Before purchasing cement silo the client should make sure that bulk cement is available in the area.

Coming to the machine, the operator uses the prepared mortar to produce concrete blocks. To do this he uses the hydraulic joysticks and follow 3 main stages.

- Loading the mortar cart with mortar.

- Fill the mold with mortar.

- Using vibration and press power to compact the mortar.

- Take out the shaped blocks from the molds.

- Pushing the blocks that are on the pallet out and getting an empty pallet in the pressing table again for the new cycle

The products that are pushed out of the machine are delivered to the curing area using pallet wheelbarrows.

Semi-Automatic Block Making Machine Advantages

Depending on the installation country and project budget, Semi-automatic machines have different advantages that are listed below:

- The semi-automatic machines are more economical, so for projects with a limited budget, they play a critical role.

- There is no need for a forklift for the production process. So there won’t be extra expenses with the machine.

- There is no need for wheel loaders. The aggregate can be loaded into the hopper with wheelbarrows and reduce the initial investment. Note that if needed the batching system can be fully automatic as well.

- The simpler system is very easy to troubleshoot, so if anything happens to the machine. There won’t be any need for engineers to do troubleshooting for you in case of breakdowns.

- The total energy consumption is lower than fully automatic machines.

- The mold filling system and vibration are fully automatic to ensure the same quality blocks on each press.

Semi Automatic Block Making Machine Disadvantages

while discussing the advantages we need to also discuss the downsides of the semi-automatic machines.

- Semi-automatic machines require more workers compared to fully automatic machines. So for countries with high labor costs, it won’t be very cost-effective.

- Semi-automatic machines require more land for installation compared to fully automatic options. If land is expensive in your area, you might reconsider the semi-automatic options.

FAQs About Semi-Automatic Concrete Block Making Machines

- Why do I need 7 people to fully operate a semi-automatic concrete block machine?

The details for the number of workers are as below:

1 or 2 personnel to fill the aggregate hopper. This depends on the machine size.

1 mixer operator.

1 machine operator.

3 wheelbarrow operators.

1 pallet loader to the pallet magazine. - In which countries have we installed semi-automatic block making machines?

we have started our internation business in 2003 and up to now we have installed semi-automatic block making machines in Ghana, Gabon, Zimbabwe, Mozambique, Malawi, DRC, Gabon, Kenya, Somalia, Syria, Djibouti, Ethiopia, Nigeria, Benin, Ivory Coast, Gambia, Sierra Leone, Senegal, Gambia, Romania, Hungary, Guyana. - Which Semi-automatic block making machine is the most popular and best-selling model?

Generally, 2 models are the most selling models due to their suitable capacity and reasonable price:

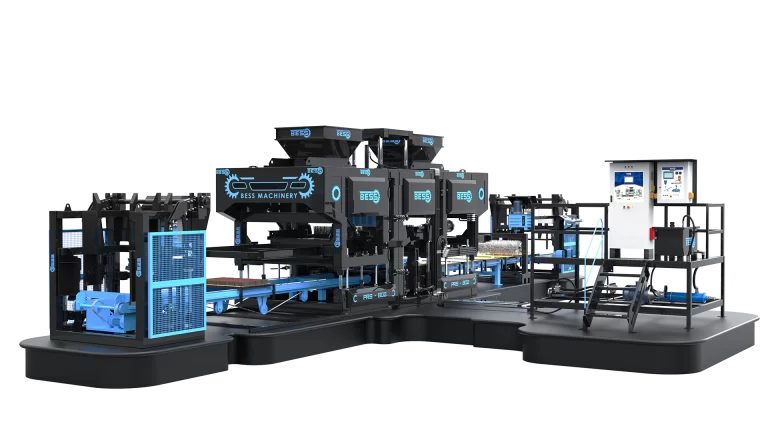

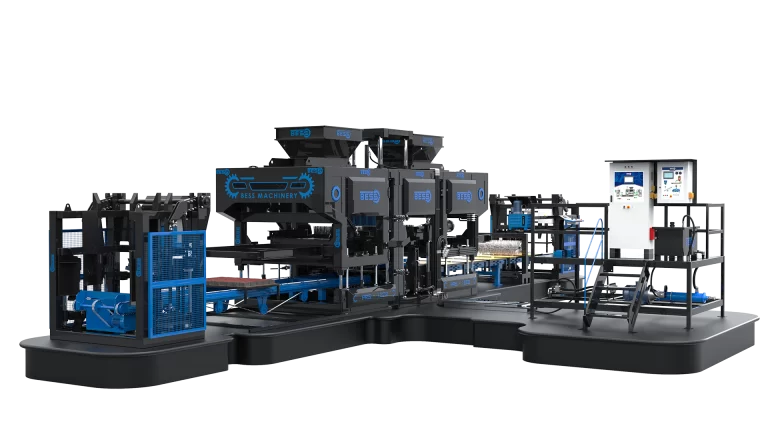

Fully Automatic Block Making Machine Working System

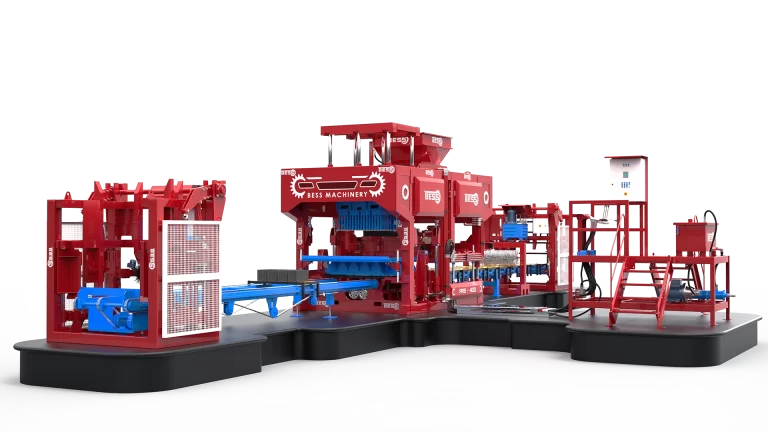

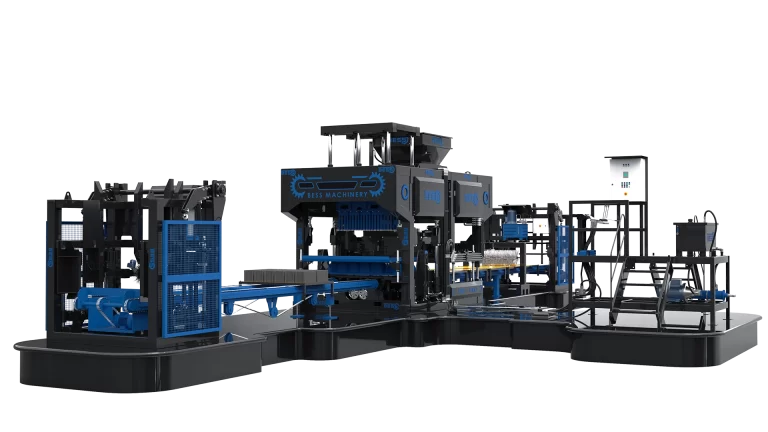

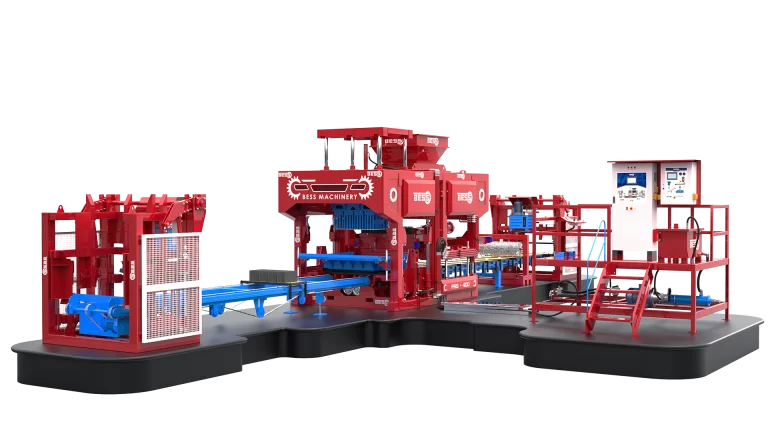

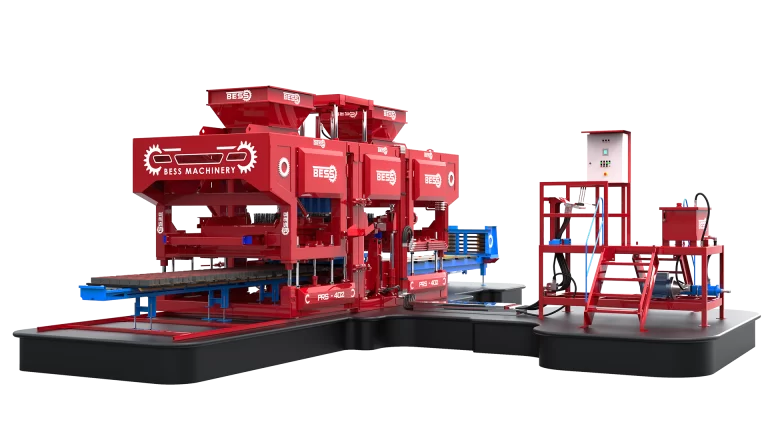

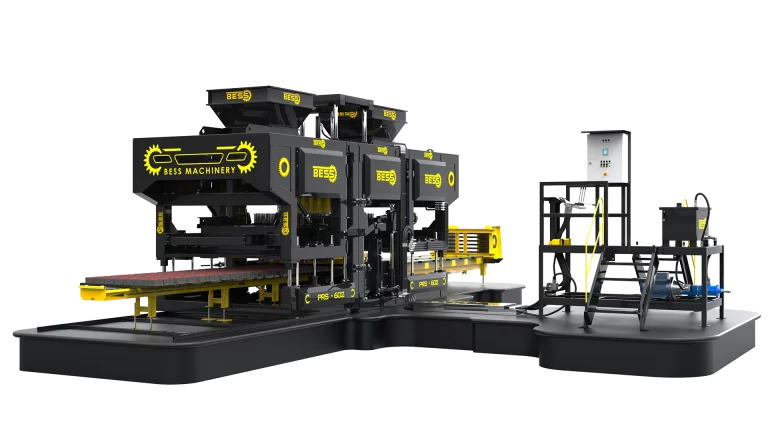

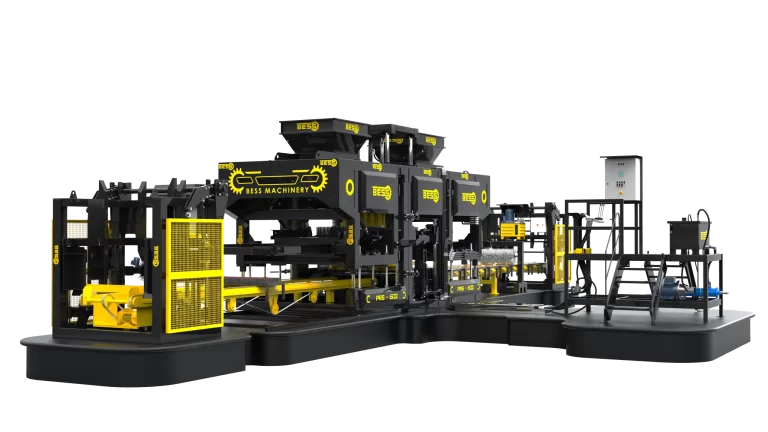

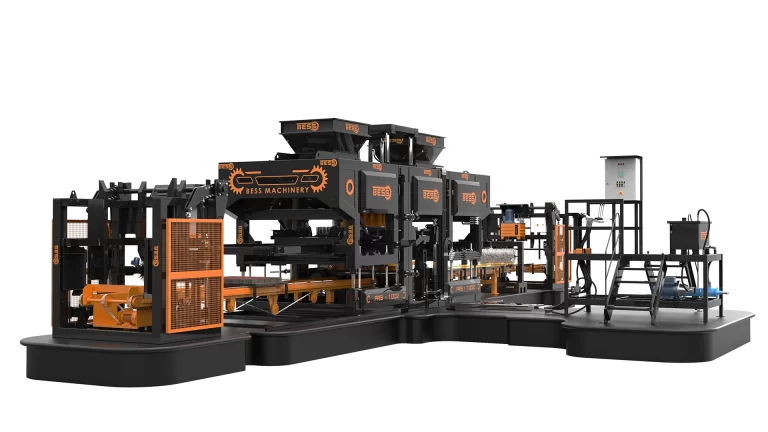

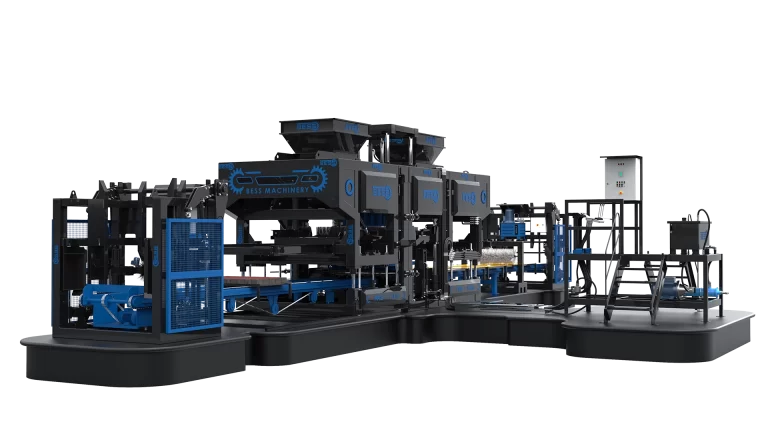

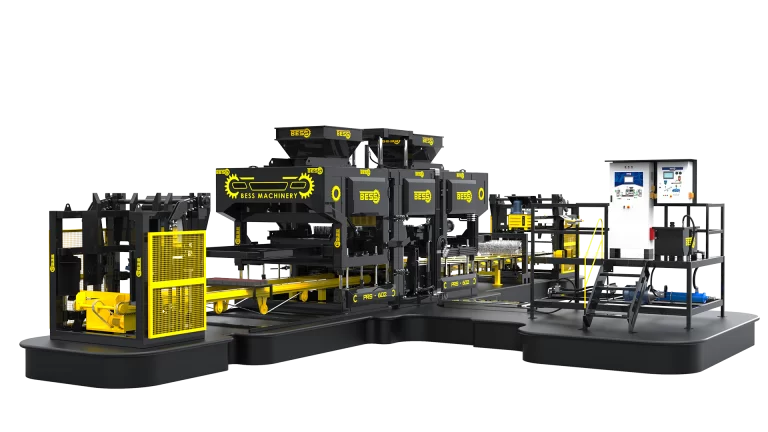

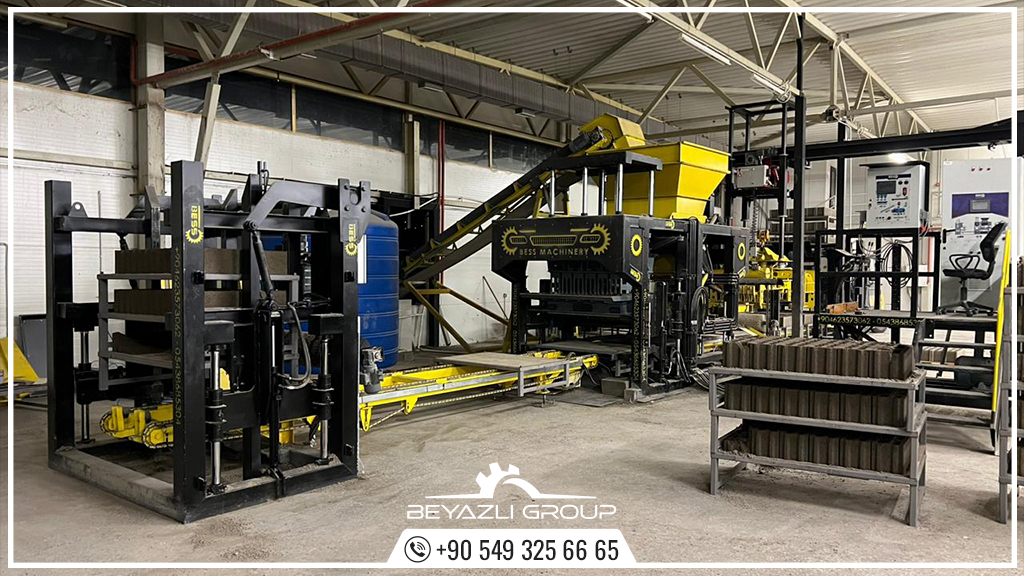

Below is a fully automatic block making machine plant layout.

As you can see, a forklift and wheel loader are necessary to operate the plant. The mixer operator is removed in the fully automatic system, and only one operator is on the machine. This operator watches the process and only interferes if needed.

The aggregate, cement, and water are all weighed before mixing to make sure you get an accurate mortar for each batch.

Pallets on the fully automatic machines have legs and are stacked on each other. Then they are delivered to the curing area using a forklift.

The products are collected with a palletizer robot in fully automatic machines.

Fully Automatic Block Making Machine Advantages

Generally, for big projects fully automatic machines are preferred.

Fully automatic machines have a lot of advantages that might be very important for some projects.

- All the materials are weighed before adding to the mixer. So, the mortar quality is always the same.

- The number of staff needed for the whole plant is reduced only to 3. If labor cost is expensive in your area you might like to choose fully automatic machines.

- A smaller curing area is needed for fully automatic machines, so the total land needed for fully automatic machines is significantly smaller than semi-automatic version.

- The production line is not connected to the operator controlling the machine, so the production speed is the same all the time.

- After a certain capacity (more than 10.000 blocks) only fully automatic machines are available because the pallets will be too heavy to be delivered by pallet wheelbarrows.

Fully Automatic Block Making Machine Disadvantages

Among all the advantages of fully automatic block making machines there are a few points that you might need to consider before choosing them.

- Fully automatic concrete block machines are more expensive compared to semi-automatic versions.

- You need a stable power supply to ensure a smooth process.

- A forklift and wheel loader should be available to work with the machine.

- A cement silo is necessary to provide cement for the machine. bulk cement should be available in the city where the machine will be installed.

FAQs About Fully Automatic Concrete Block Making Machines

- How many people are needed to fully operate a fully automatic concrete block making machine?

totally you need 3 personnel to fully operate a fully automatic plant.

1 wheel loader operator to fill the aggregate hopper.

2 forklift operators. - In which countries have we installed fully automatic block making machines?

we have started our internation business in 2003 and up to now we have installed fully automatic block making machines in Ghana, Somalia, Georgia, Ireland, Libya, Iraq, Belize, Kazakistan, Morocco, Egypt, and United Arab emirates. - Which fully automatic block making machine is the most popular and best-selling model?

Generally, 2 models are the most selling models due to their suitable capacity and reasonable price:

Conclusion

Concrete blocks are available in different capacities and automation levels. The best machine for your project is directly related to the factors below:

- The country where you will install the machine.

- The total budget for the whole plant.

- The number of blocks that are planned to be produced per shift.

- The land for the project.

Based on the factors below, you can choose the right option for your project. If you need any further details, you can contact us anytime to get further details about the machines, their working system, and prices.