Paving Block Machines Explained

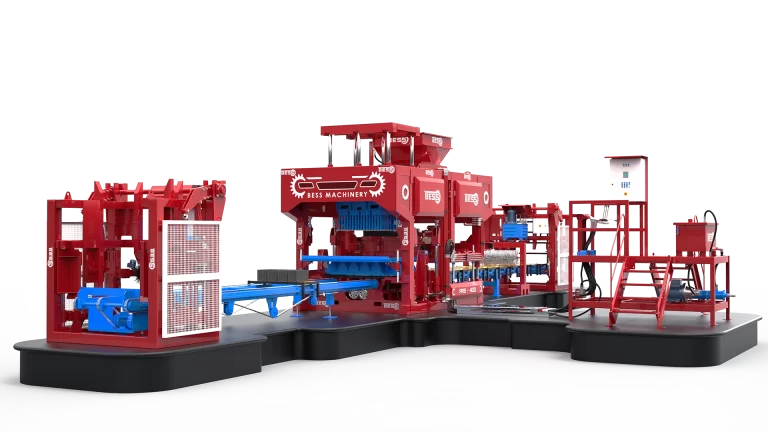

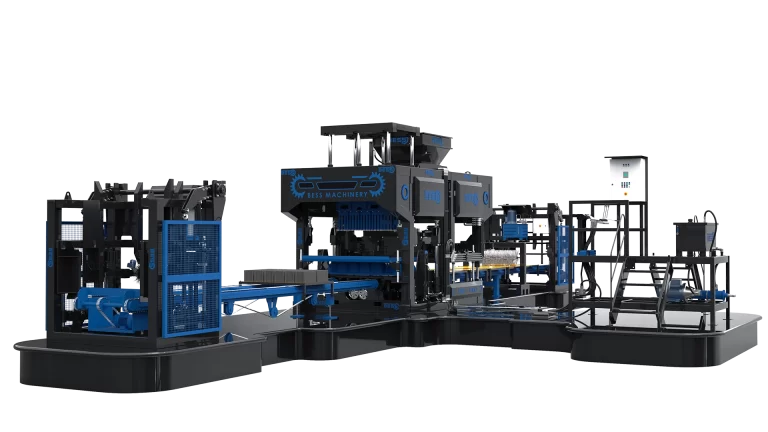

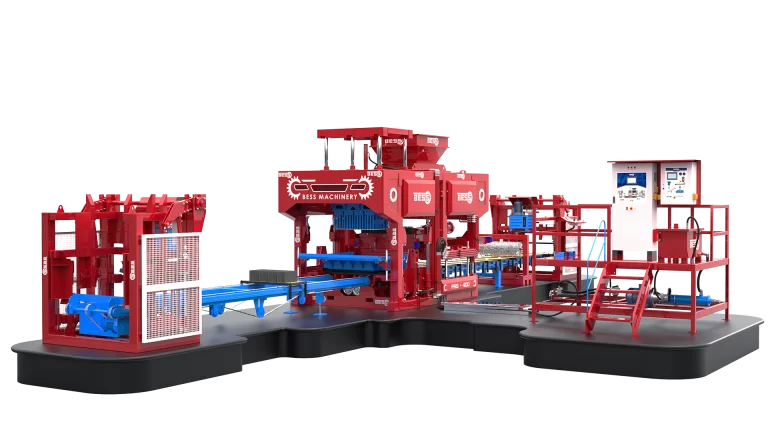

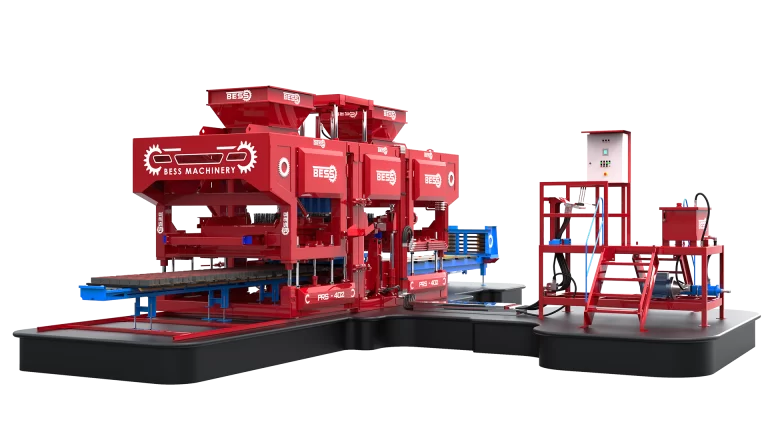

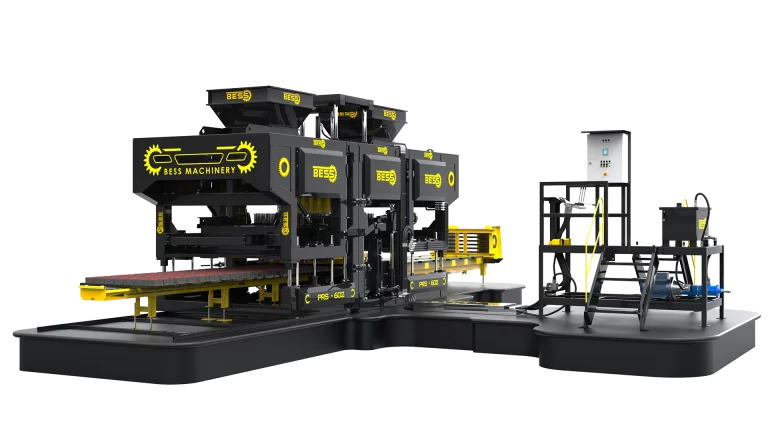

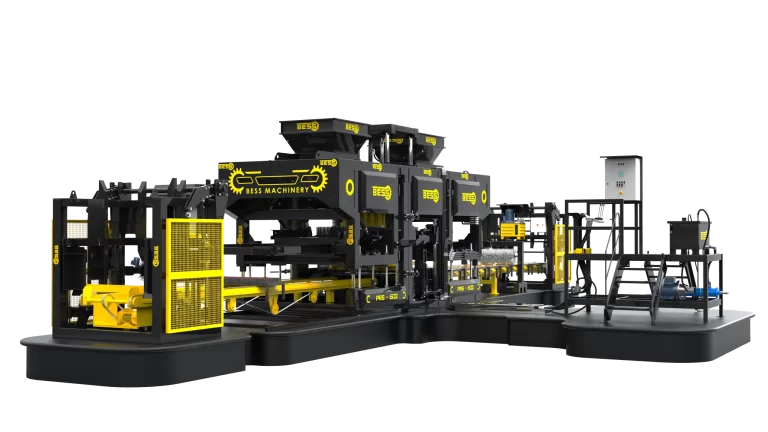

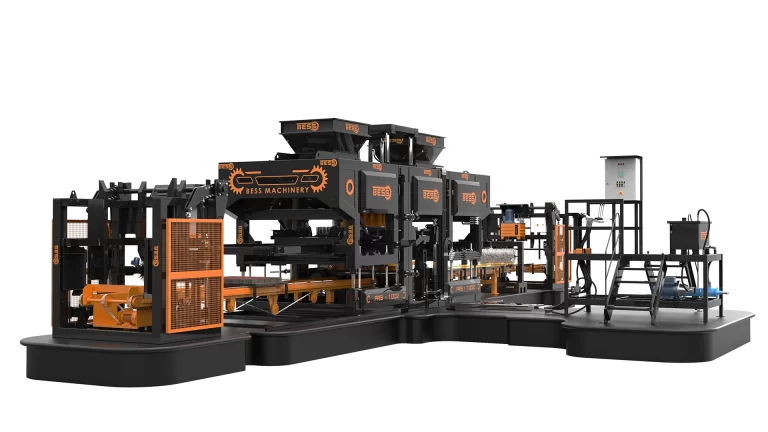

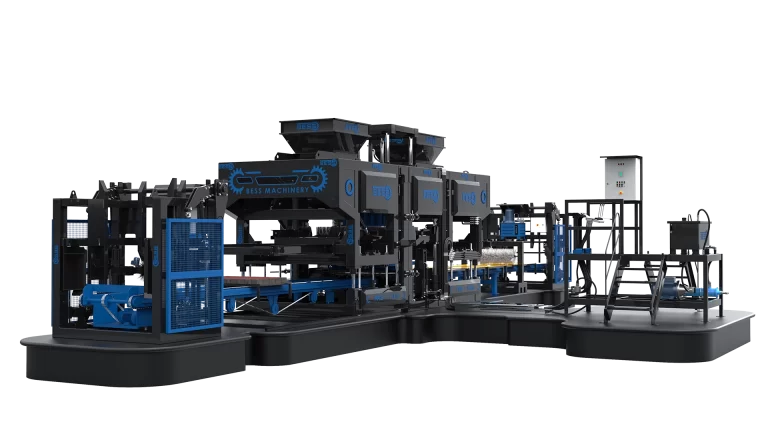

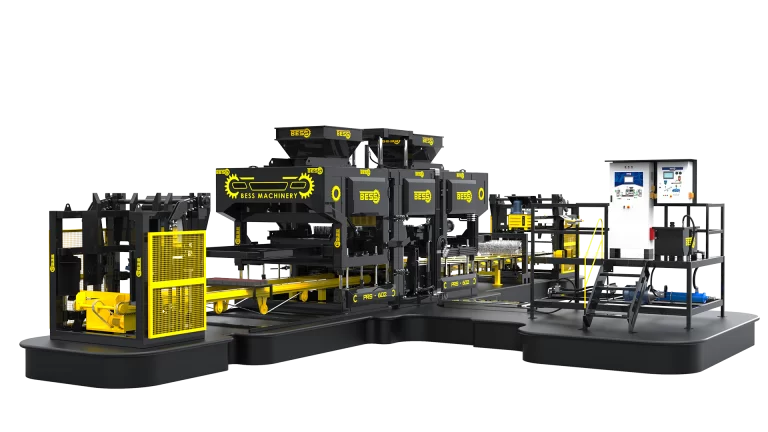

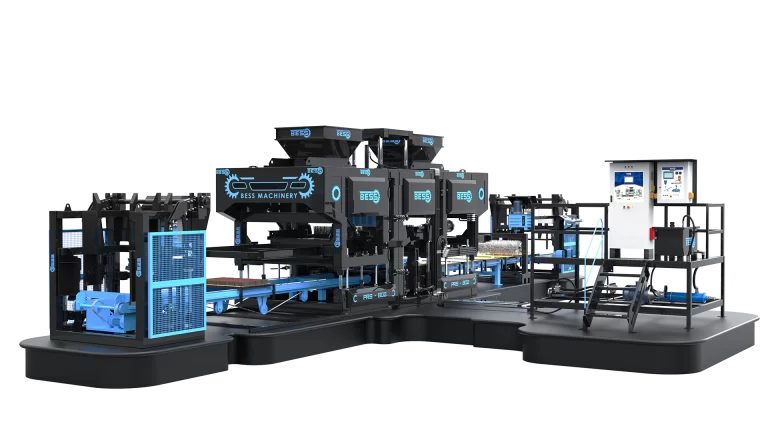

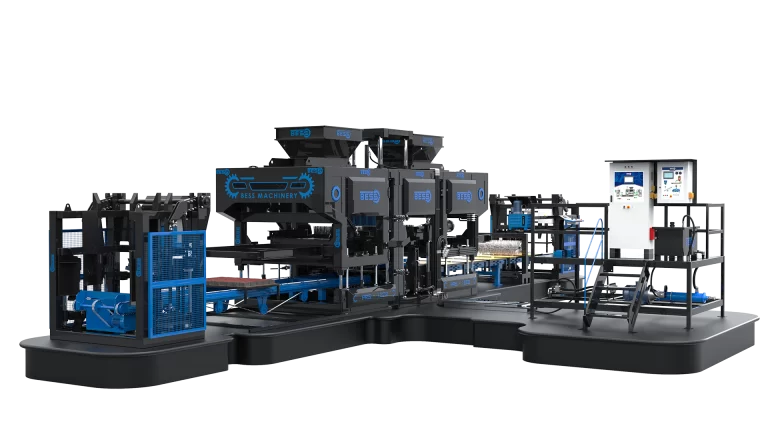

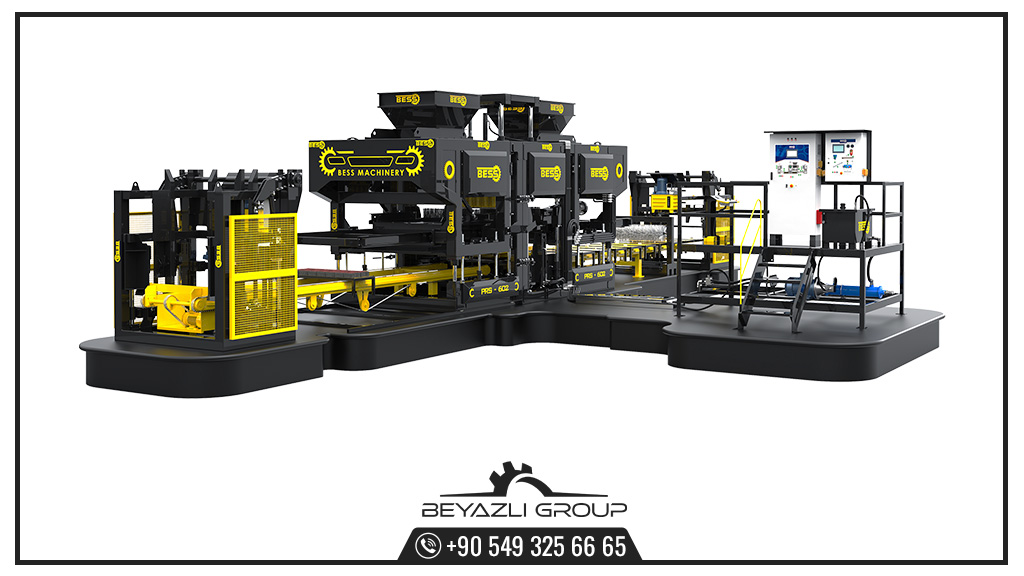

A paving block machine is machine designed to produce concrete paving blocks in different shapes, sizes, and colors. These machines use vibration and hydraulic pressure at the same time to form durable blocks.

Paving blocks are widely used in urban development, landscaping, and infrastructure projects because paving blocks are strong, long-lasting, and visually appealing. Depending on the machine’s design, it can produce various products, including single-layer and double-layer paving blocks.

For businesses, the main advantage of a paving block machine is its ability to produce high volumes with consistent quality. By choosing the right model, companies can match production capacity to market demand, control costs, and maximize profitability.

Paving Block Machine Types

There are two main types of paving block machines:

- Single Layer Paving Block Machines:

These machines produce paving blocks in a single layer, meaning the surface and the base are made of the same concrete mix. Single-layer machines are often called hollow block machines, because most of the single layer machine owners use them to produce mostly hollow blocks and solid blocks. Most businesses focused mainly on paving block production prefer double-layer machines for better surface quality.

- Double Layer Paving Block Machines:

These machines produce paving blocks with two separate layers — a strong base layer and a top layer made with finer materials for improved appearance and durability. Double-layer machines are ideal for decorative paving blocks used in high-traffic or visually important areas.

Important note: that both machines can produce all shapes, including hollow blocks, solid blocks, paving blocks, and curbstones. The only difference is the double-layer system.

Please read 10 Different Products Produced by Concrete Block Machine for further details.

Paving block machines come in three automation levels:

- Semi-Automatic:

Requires more operator involvement (8 personnel), especially for pallet transport and material handling. Popular in countries like Ghana, Nigeria, and Libya, where labor costs are lower and operators are readily available. Suitable for small to medium-scale production. - Automatic:

Some processes, such as material feeding and pallet movement, are automated. Common in places like Iraq, Morocco, and some European countries, where businesses want to balance automation with moderate investment. - Fully Automatic:

Handles the entire process from material feeding to product stacking with minimal labor. Preferred in countries with higher labor costs, such as France, the United Kingdom, and the United Arab Emirates, and ideal for large-scale, continuous production.

If you need help choosing the best machine for your business please read ”Semi-Automatic Or Fully Automatic Block Machines, Which One Is The Best for You?”.

Paving Block Machine Capacities and Output

The capacity of a paving block machine is measured in two ways — by the number of blocks produced per shift and by the total paving area in square meters. The most common and practical measurement in the industry is square meters (m²) per 8-hour shift, as it reflects the actual coverage for paving projects.

Small and medium-capacity machines can produce around 300–700 m² of paving blocks per shift. The PRS600 Semi-Automatic Paving Block Machine is an example of a medium-capacity model.

Larger fully automatic models can produce around 800–1,000 m² of paving blocks per shift. The PRS1200 Fully Automatic Paving Block Machine is an example of a high-capacity model.

Smaller machines are often preferred by startups or projects with a limited budget, as they require lower initial investment and have lower operating costs. Larger machines, on the other hand, are chosen primarily for their high production capacity, making them ideal for established companies aiming to meet large-scale demand.

What to Check Before Purchasing a Paving Block Machine

Before making an investment, it’s important to review the machine’s quality and the materials used in its construction. A solid chassis, high-quality welding, and reliable hydraulic and vibration systems will ensure long-term performance.

Verify the mold compatibility to ensure the machine can produce various shapes and sizes of paving blocks, as well as other products such as curbstones or hollow blocks. Having the flexibility to switch molds can increase profitability.

Evaluate the after-sales service and spare parts availability offered by the manufacturer. Quick support and easy access to parts can prevent long downtimes and keep production running smoothly.

Finally, confirm the power and installation requirements of the machine. Ensuring your site has the right electrical capacity, space, and handling equipment will make the installation process much easier.

If you need mode details please read our article Top 6 Mistakes to Avoid When Buying a Block Making Machine.

Paving Block Machine Installation & Setup Requirements

Before installing a paving block machine, the production site must be properly prepared. The area should have a solid, level concrete foundation capable of supporting the machine’s weight and absorbing vibration during operation. We provide the foundation layout free of charge based on the customer’s land details, ensuring the setup meets all technical requirements.

All paving block machines require a three-phase power supply. Smaller machines need around 50 kW, while larger models can require up to 140 kW depending on the selected equipment. For higher-capacity machines, you may need a larger transformer or a properly sized generator.

Ensure there is enough space for material storage, product curing, and vehicle movement. Proper layout planning allows for efficient workflow, from raw material delivery to finished product stacking.

Finally, have the necessary installation equipment ready, such as cranes or forklifts, to position the machine and molds safely. Preparing these details in advance will reduce delays and allow for faster commissioning.

Maintenance and Longevity Tips for Paving Block Machines

Regular maintenance is essential to keep a paving block machine running efficiently for many years. Following the manufacturer’s service schedule for lubrication, hydraulic oil changes, and inspection of vibration motors will prevent unexpected breakdowns.

Keep the machine clean and free of excess concrete buildup, especially around the mold and vibration table. Residue can affect product quality and cause unnecessary wear on moving parts.

Check all electrical and hydraulic connections periodically to ensure they are secure and functioning properly. Replace worn parts promptly to avoid damaging other components.

Proper operator training is also key. Skilled operators can spot early signs of mechanical issues and handle the machine in a way that extends its service life, reducing downtime and repair costs.

Choosing the right paving block machine is a decision that directly affects production capacity, product quality, and long-term profitability. By understanding the different machine types, capacity ranges, installation requirements, and maintenance practices, businesses can invest with confidence.

Whether selecting a medium-capacity model like the PRS600 or a high-capacity option like the PRS1200, matching the machine to your production goals ensures maximum efficiency. With proper installation, regular maintenance, and reliable after-sales support, a paving block machine can produce premium-quality blocks for many years.

For tailored recommendations based on your project needs, Beyazli Group offers expert guidance, technical support, and high-quality paving block machines manufactured to international standards. With over 62 countries served worldwide, we combine advanced engineering with reliable after-sales service to ensure long-term success for our customers.