Why Start a Concrete Block Business in 2025-2026?

The demand for concrete blocks is growing due to rapid construction, housing shortages, and population growth. This is happening even faster especially in developing countries in Africa, the Middle East, and South America. the products that concrete block machines produce are very popular for construction projects because they are durable and economic.

Governments and private sectors are investing huge amounts in long-term housing and urbanization projects. Especially in 2025 and 2026, the main focus is on:

- Affordable housing projects

- road construction and their sidewalks

- commercial and industrial buildings

There is a great opportunity for investors to enter the concrete block production industry with low startup risks and high return potential. With the right concrete block machine and raw materials, you can start producing high-demand products like hollow blocks, solid blocks, paving blocks, and curbstones.

These concrete products are essential for any construction project.

First Step: Create a Business Plan

Starting a concrete block production business without a business plan is like building a house without any foundation. The business plan shows you the right way and prevents wrong decisions.

Based on the budget, the details below should be clear:

- The machine and number of molds to be bought.

- Pallets to be provided based on the size and type.

- land purchase.

- foundation preparation.

- factory setup.

- operational costs.

- target customers and their preferred block shapes.

- estimated cost per block and finally defining the final price of each block.

A well-thought-out business plan will save you time and energy and prevent bad surprises along the way.

Choose The Right Location For Your Factory

The location of your concrete block factory directly affects the plant efficiency, transportation costs, and profits. The location should be chosen wisely to reduce costs and be more competitive.

There are several factors that need to be considered when choosing the land:

- The land should be close to raw materials:

You need constant access to raw materials like aggregate, cement, gravel, and water. Being close to suppliers will reduce transportation costs and delays. - availability of utilities:

The land should have access to a stable electric network with suitable power. Otherwise, a generator will be needed. - land size:

The land should be suitable for a block making machine. There should be space for production area, raw material storage area, curing area, stocking area, and offices as well. - potential for future expansions:

A land that has the potential to add machinery in the future is preferred.

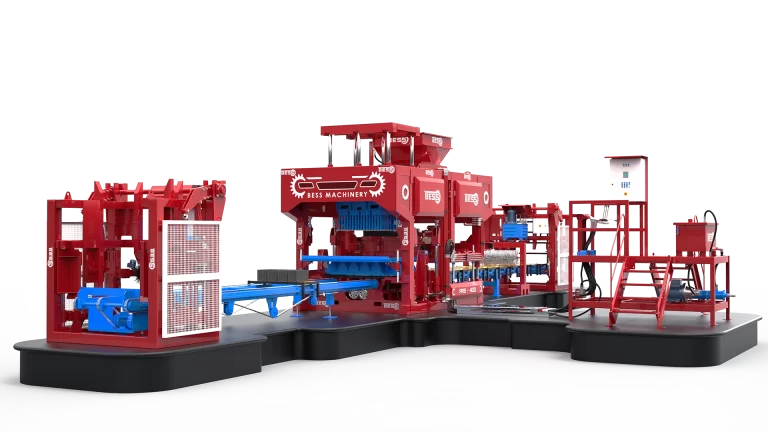

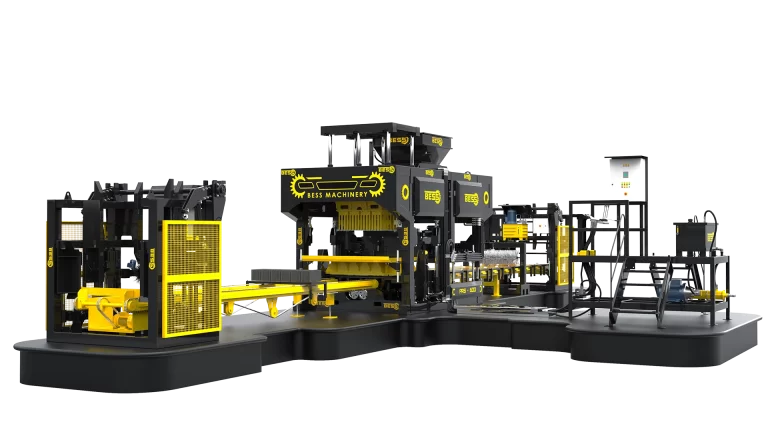

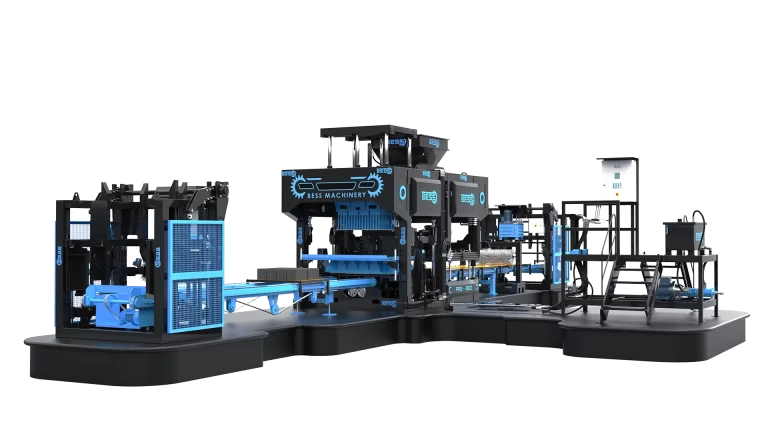

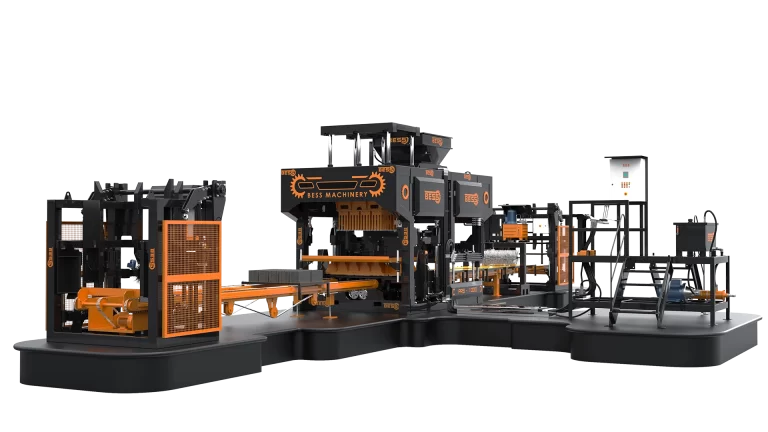

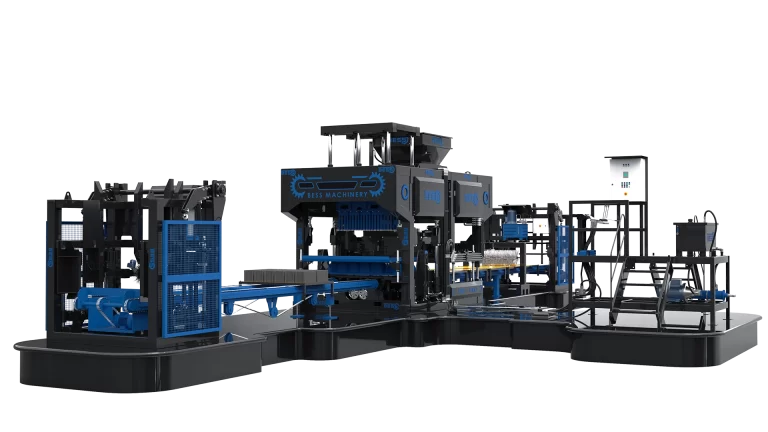

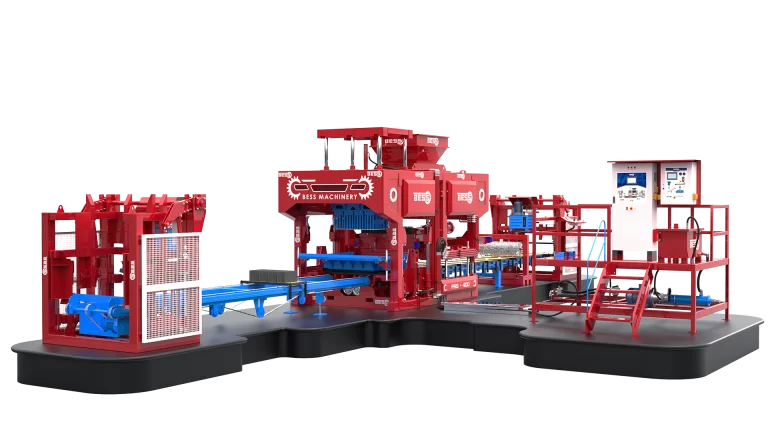

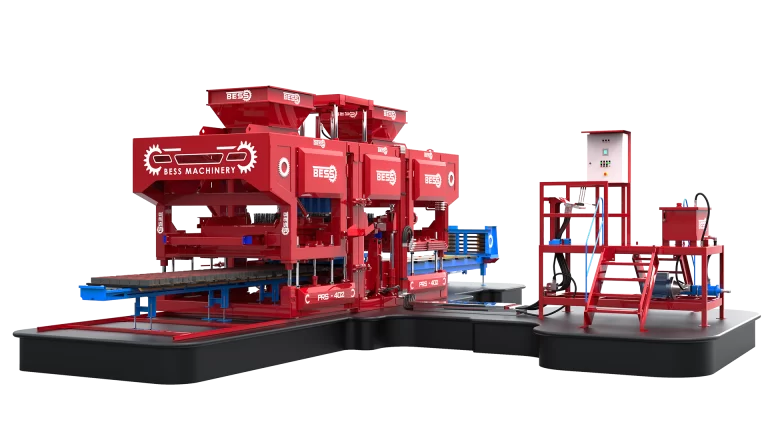

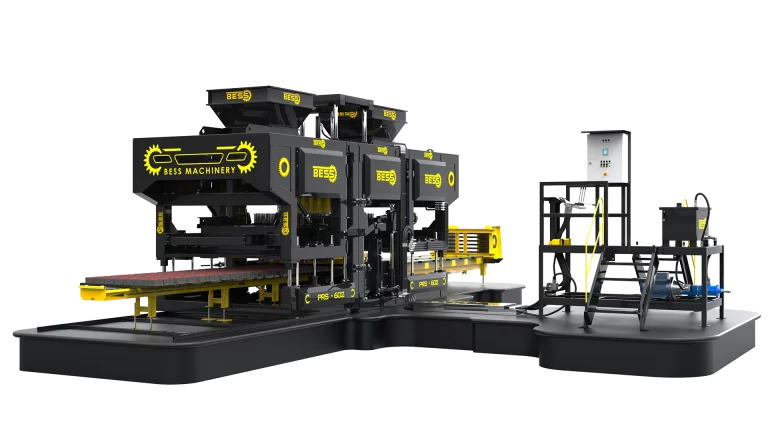

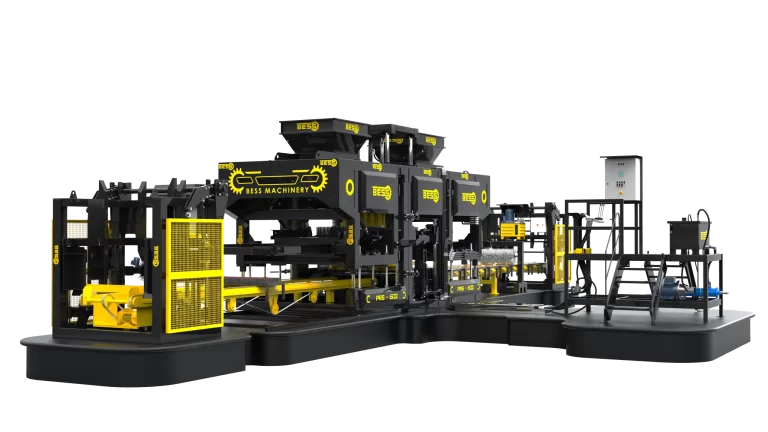

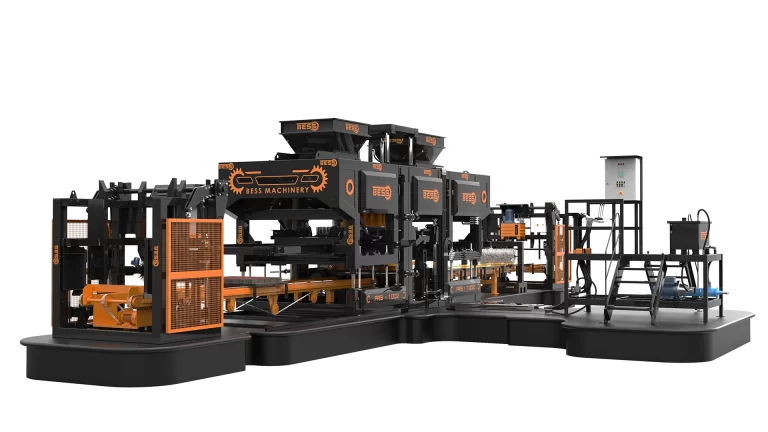

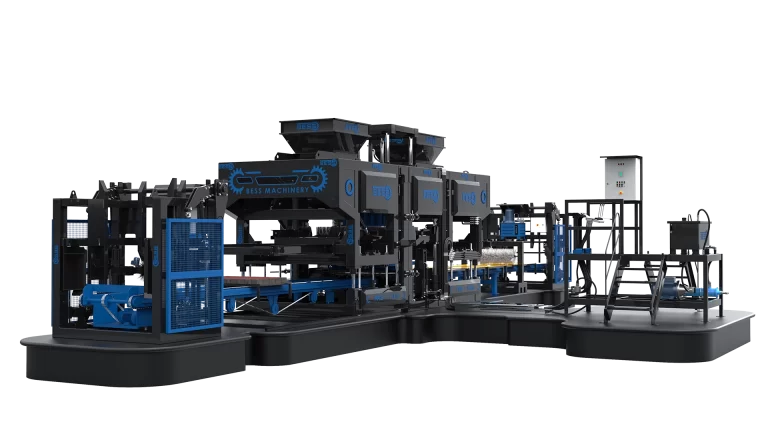

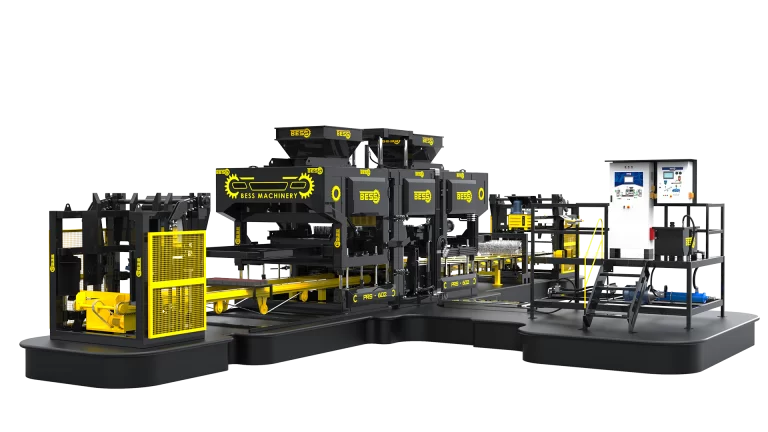

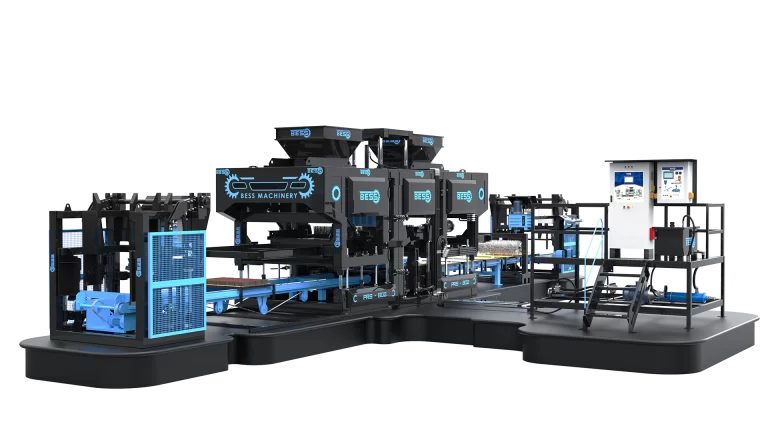

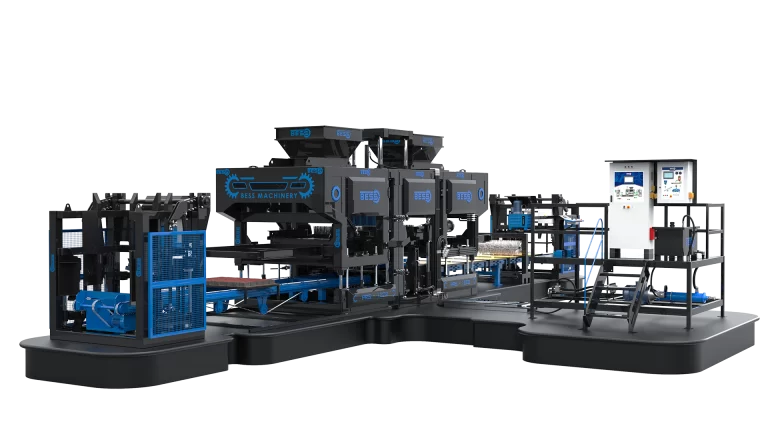

Choose The Right Concrete Block Machine

Choosing the right capacity block making machine depends on many different factors, and it is one of the most important decisions to be made.

Choosing the right block machine will affect production speed, product quality, staffing needs, and finally, the profit you will make from the business.

If you are wondering whether to choose a semi-automatic concrete block machine or a fully automatic one, you need to check many factors. It won’t fit in this article to discuss all the details regarding the suitable machine. Please read about semi-automatic or fully automatic block machines. Which one is the best for you?

Choose The Right Products for Your Production Line

One of the most important steps in setting up a concrete block production business is deciding on the products to be manufactured.

Each product serves a different purpose in the construction, whether it’s hollow block, solid block, paving block, or curbstone. Choosing the right shapes of products based on your local demand can increase profit and reduce waste.

Choosing the block shapes should be investigated before buying the concrete block machine.

Hollow blocks, solid blocks, and hollow floor blocks are used in building walls, while paving blocks and curbstones are used for roads and walking paths. Each one of the mentioned blocks has many different shapes as well.

Some concrete products have different production procedures as well. For example, there are double-layer paving blocks that are different from single-layer blocks. You can read 10 Different Products Produced by Concrete Block Machine for further details.

Hire Personnel Based on Your need

Hiring the right number of staff with the right skills is very important for the performance of the plant. The staff skills are related directly to the automation level and capacity of the machine.

For semi-automatic concrete block machines, you need around 8 staff.

For fully automatic machines, you only need 3 staff.

Of course, for fully automatic machines, you need more skilled staff because of the software and programs.

Normally, the staff are trained when the installation team comes and install the machine. They will be trained how to operate the machine, how to change the mold, and how to troubleshoot the machine if something goes wrong.

Avoid Common Startup Mistakes

Starting a concrete block production business can be highly profitable—but only if you avoid common mistakes that lead to costly delays or failure. Many new businesses rush into buying machines or opening production sites without doing enough research or planning. This can result in poor product quality, low efficiency, or even complete shutdowns.

One of the biggest mistakes is choosing the wrong type of machine for your needs. For example, selecting a small capacity semi-automatic machine when your market demands high volumes can limit your growth.

New business owners also often overlook the importance of layout planning and staff training. A poorly organized facility can slow down production, and untrained staff can cause machine damage or product defects.

please check Top 6 Mistakes to Avoid When Buying a Block Making Machine for more details