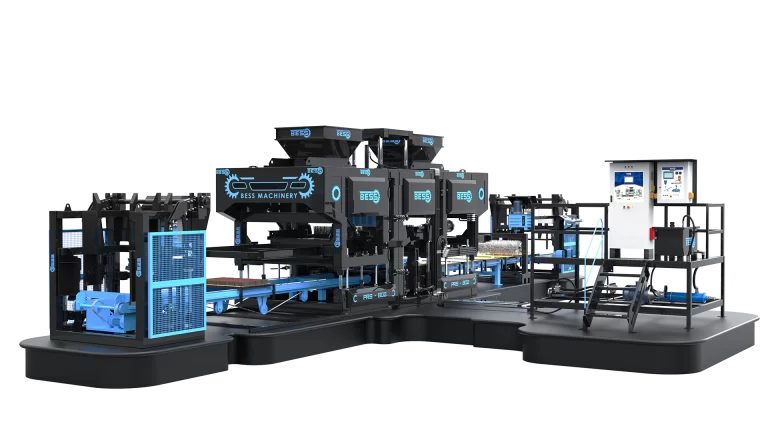

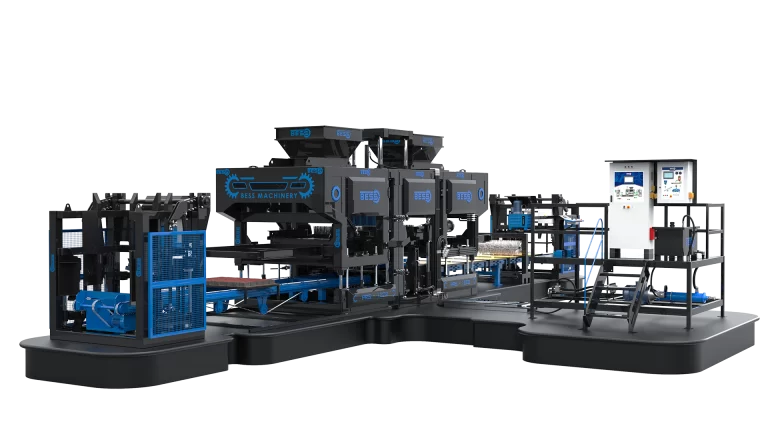

Electric Power: The First Step in Machine Installation

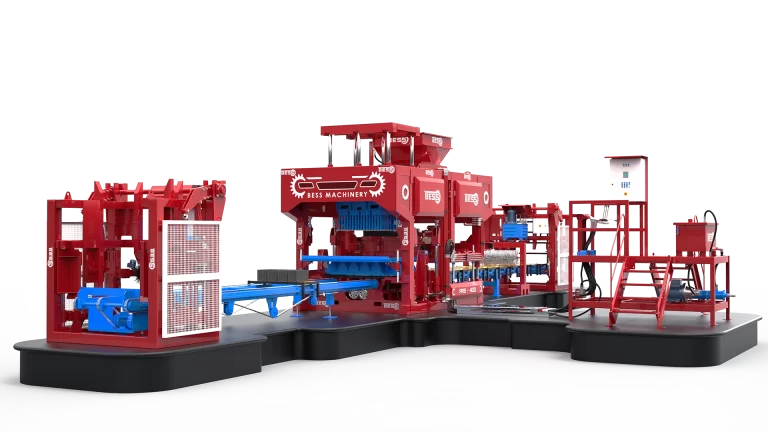

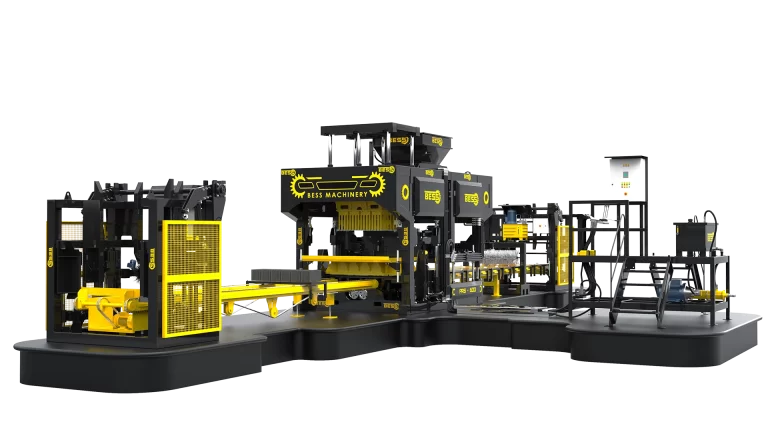

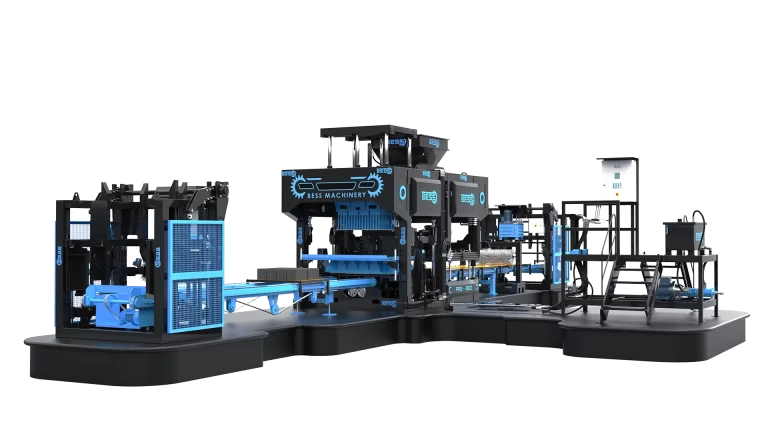

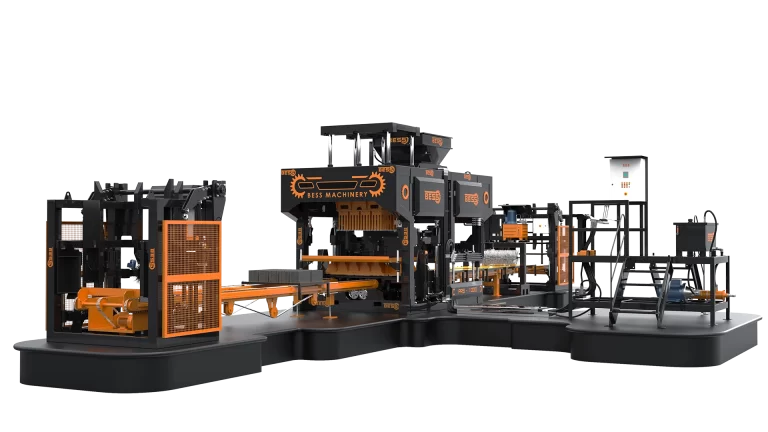

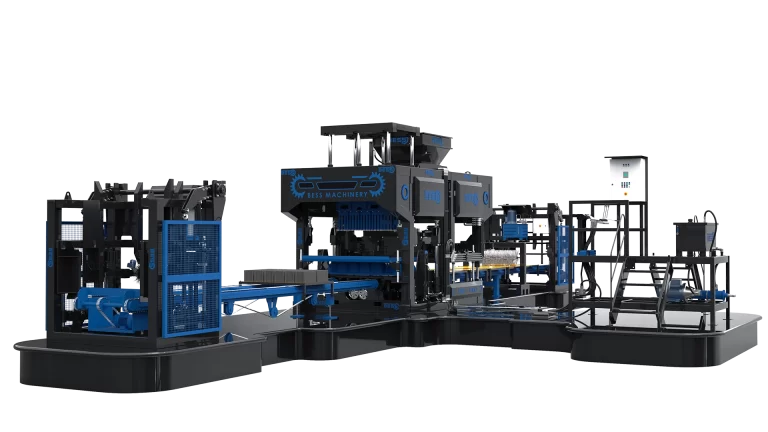

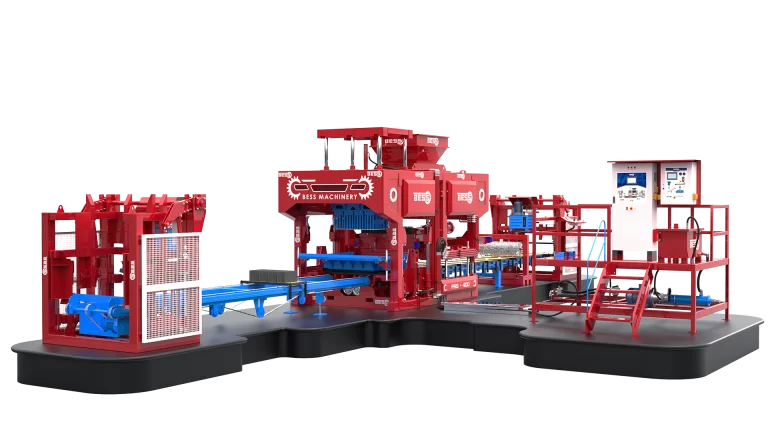

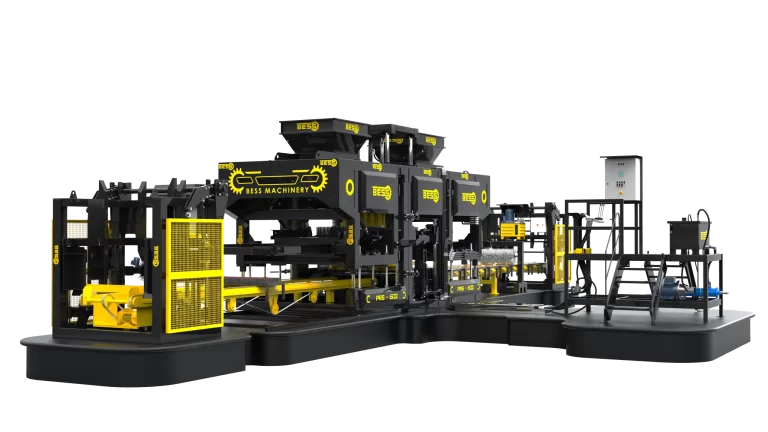

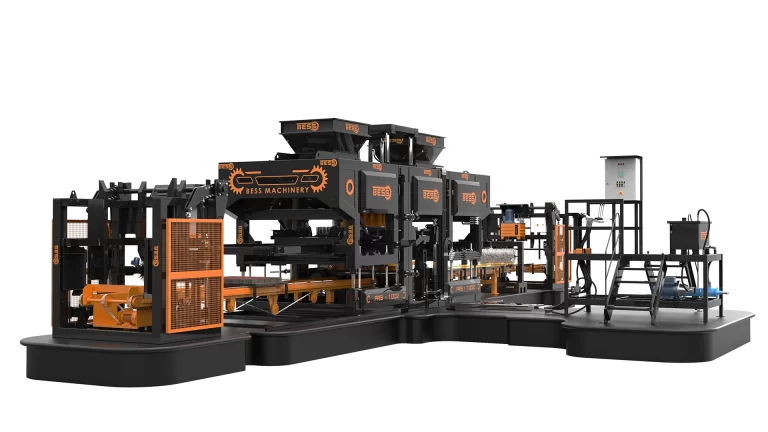

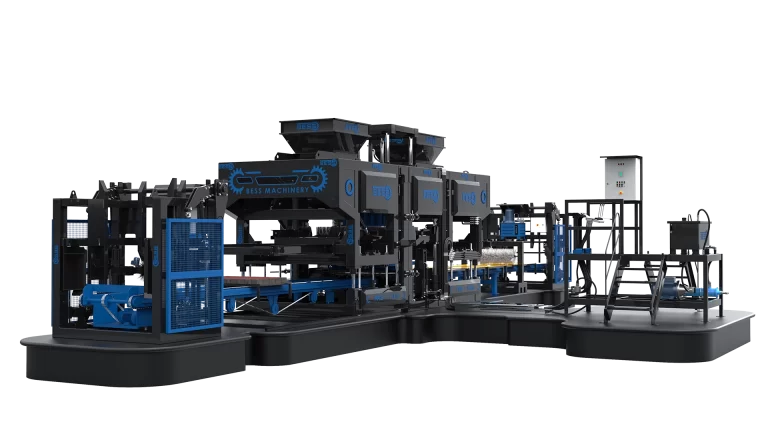

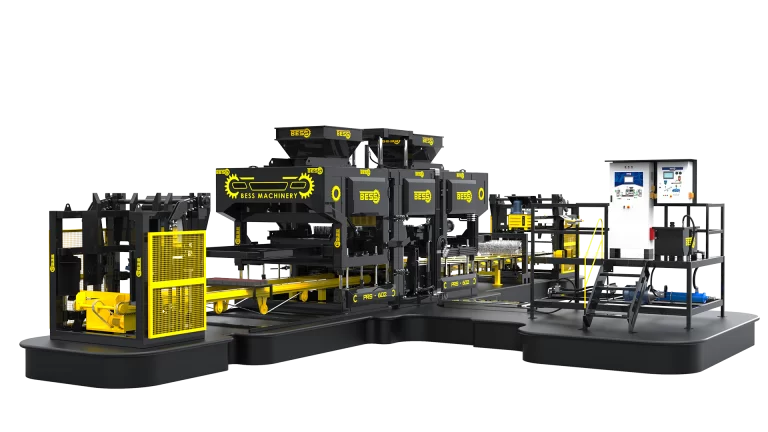

Before a concrete block making machine is installed, one of the most important factors to consider is the power source. Whether you’re setting up a small semi-automatic machine or a large fully automatic production line, reliable electric power is essential.

Without the right electric power, even the most advanced machines cannot operate efficiently and safely.

Electric power directly affects machine performance, production capacity, and durability in long-term. Voltage fluctuations or current, or unstable supply can cause frequent shutdowns, overheating, or even permanent damage to motors and hydraulic system. That’s why planning your power system from the beginning saves both time and money.

Depending on your location, you may choose grid power or generator. Each option has its own technical requirements, advantages, and limitations. Choosing the right power setup ensures smoother installation, uninterrupted production, and fewer maintenance problems in future. In the following sections, we will guide you through how to evaluate your machine’s power needs and decide between grid electricity and generator use.

Know Your Block Making Machine’s Power Needs

Every concrete block making machine has a specific power requirement. Before installation, you need to check how much electricity your machine needs to work properly. This includes the total kilowatts (kW) or kilovolt-amperes (kVA) it uses and whether it needs 3-phase power, which is the standard for industrial machines.

If you’re not sure about these details, ask your machine supplier to provide the full power chart.

Most machines do not use the same amount of power all the time. When the machine starts, it uses more power for a few seconds. This is called the startup load or peak load. After that, it uses less power during normal operation. You need to choose a power system that can handle both the peak and regular loads without problems.

You can find your machine’s power requirements in the technical documents or by asking the supplier. Knowing this information helps you choose the right generator or prepare your grid power setup. If the power is too weak or unstable, the machine may stop or get damaged. That’s why it’s important to check the power needs before starting production.

Using Grid Power

If your factory has access to a stable electricity grid, this is usually the easiest and most affordable power option. Industrial concrete block machines work with 3-phase power, This is common in industrial areas. Before installation, make sure that your electrical system can supply enough voltage and current for your machine.

Even if grid power is available, you must check the voltage stability. If the voltage goes up and down too much, it can damage the motors and other parts of the machine. In these cases, using a voltage stabilizer or surge protector is strongly recommended. A stable power source helps the machine run smoothly and protects your investment.

In some areas, the local voltage may not match the machine’s requirements. For example, the grid may supply 220V or 440V, while the machine needs 380V. In these cases, you may need to install a step-up or step-down transformer to adjust the voltage. It’s also important to make sure your system is properly grounded and installed correctly.

Also, some companies ask for your grid details before manufacturing the machine to adjust the machine to your local grid to avoid extra expenses.

If your country has a stable 3-phase grid and few outages, grid power is the best and cheapest choice. It’s ideal in places like Turkey, the UAE, and Eastern Europe, where the power network can handle industrial loads reliably. In these areas, you may not need a generator at all.

Using a Generator

If your factory does not have access to grid power or if the electricity is not stable, a generator can be a good solution. Generators can provide the power your concrete block machine needs, even in remote areas. This gives you more flexibility in choosing a location for your production line and protects your business from power problems.

In many countries like Iraq, Libya, Nigeria, and parts of Sub-Saharan Africa, electricity is often cut for 4 or more hours every one or two days. If you don’t have a generator, these power cuts stop your production. Even worse, if the power goes out while mortar is still inside the machine, it can dry and harden. This requires extra cleaning, wastes materials, and may damage the equipment.

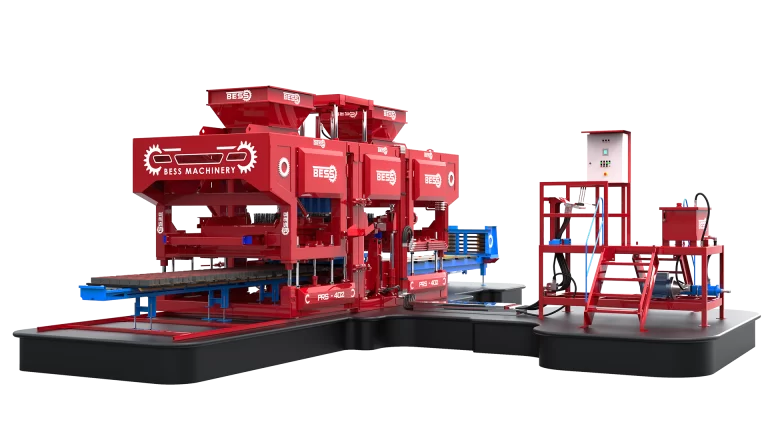

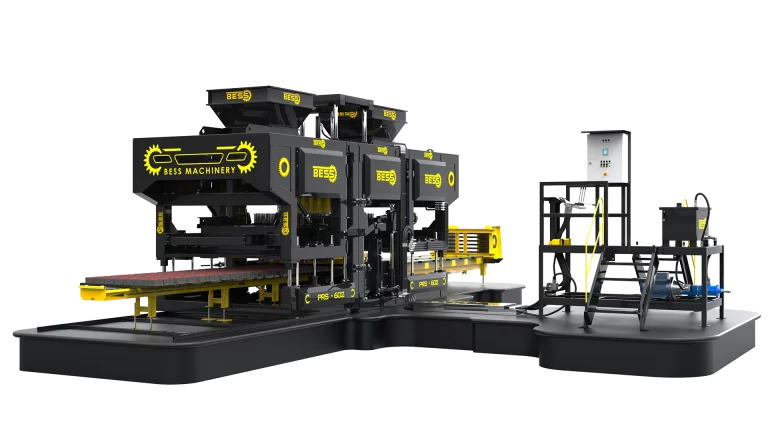

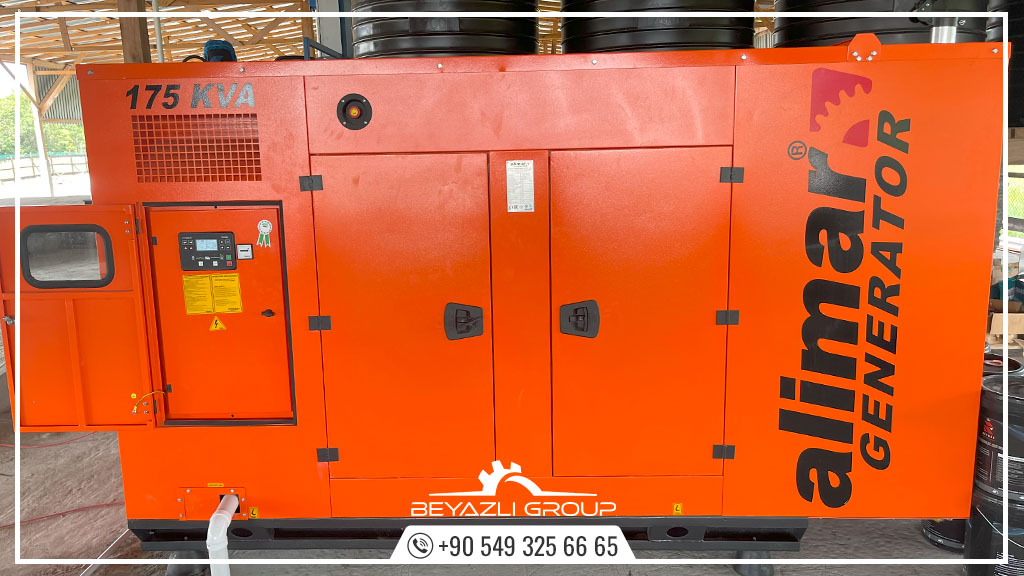

To avoid production problems, it’s important to choose a generator that is more powerful than the machine’s total power. For example, the PRS 600 machine uses around 50 kW, but we recommend using a 175 kVA generator. This may seem too big at first, but there is a good reason for it. If you are interested, please check the PRS600 semi-automatic block making machine technical details.

The machine’s vibration system uses 15 kW and works for only a few seconds, but it draws a lot of power in that short time. If the generator is too small, it can’t handle this sudden power demand, and the machine may stop or reset. A larger generator keeps everything running smoothly and protects the machine’s electrical parts from damage.

Understanding the Difference Between kW, kVA, and How Power Works

When you are choosing a power system or generator, you will see two numbers: kW and kVA. These both measure power, but they are not the same. kW means the actual power your machine uses to run. kVA means the total power that is sent to the machine, including the small amount that gets lost as heat in the cables or the motors.

Another factor is that you can’t run the generator on full power. Think of it like a car: if you push the gas pedal to the maximum all day, the engine will wear out very fast. It’s the same with generators. If you use a generator that is just enough for the machine, it will always run at full power and get damaged quickly. That’s why we recommend choosing a bigger generator — so it runs smoothly without stress, and your machine works without problems.

To estimate how much real power (kW) you’ll get from a generator, you can use this basic formula:

kW = kVA × Power Factor

In most industrial setups, the power factor is around 0.8. So for example, a 175 kVA generator will deliver about 140 kW of usable power:

175 kVA × 0.8 = 140 kW

This helps you choose a generator that meets your machine’s needs, without running too close to the limit.

How to Choose the Correct Generator for Your Block Making Machine

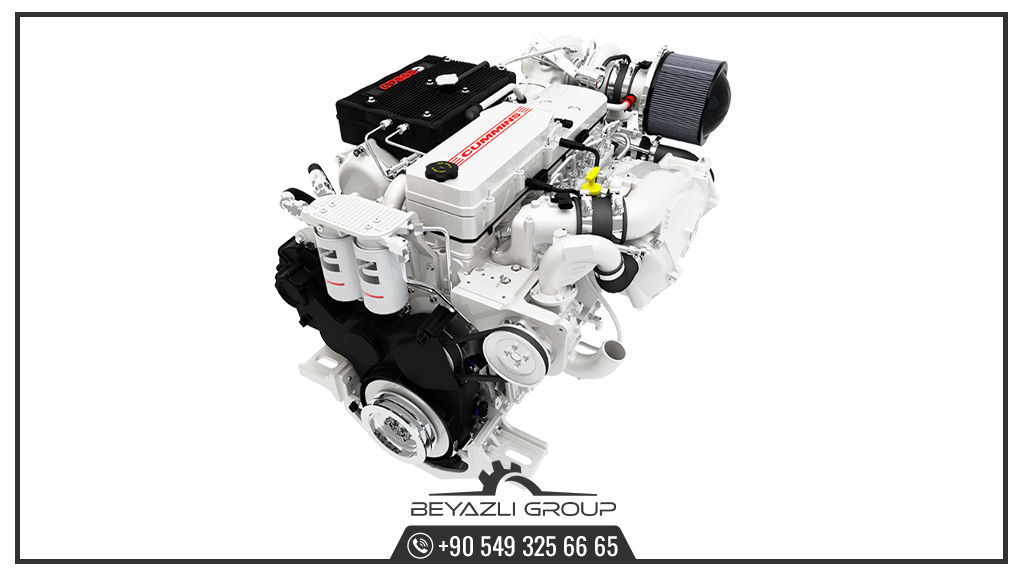

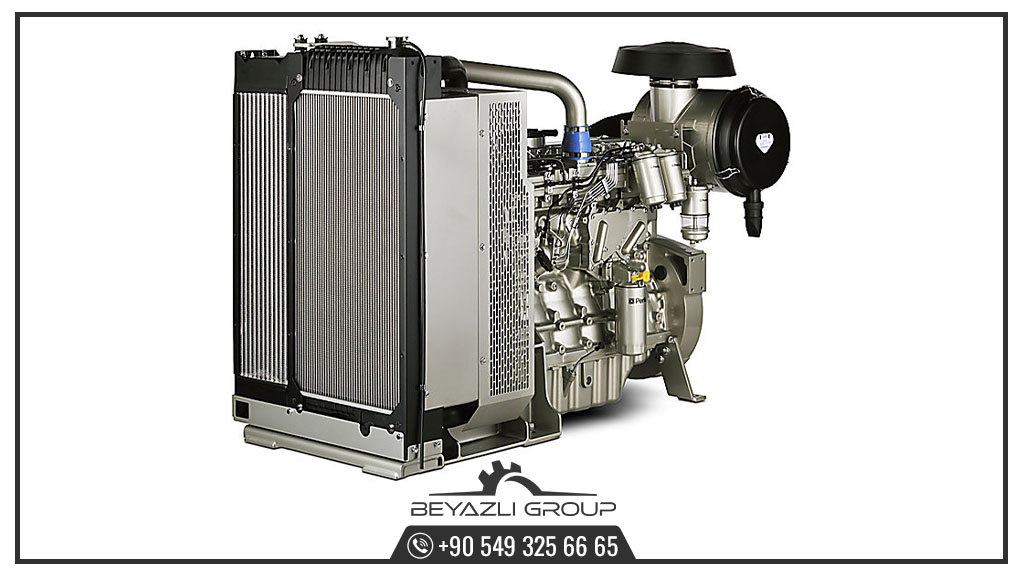

Generators come in different types and use various fuels such as diesel, gasoline, or gas. For block making factories, the most common and reliable choice is the diesel-powered generator. These are strong, durable, and well-suited for continuous industrial use. Among many available brands, Perkins engines and Cummins engines are considered some of the most trusted and high-performance options worldwide.

When choosing a generator, the most important rule is this: never choose a generator that matches the machine’s power exactly. Concrete block machines have motors that start and stop suddenly — especially the vibration motors — and they draw a large amount of power during startup. If the generator doesn’t have enough reserve capacity, the machine can stop, reset, or even suffer electrical damage.

We recommend selecting a generator that is at least 2 to 2.5 times more powerful than the total power requirement of the machine. For example, the PRS 600 machine uses around 50 kW of total power.

To calculate the required generator size:

→ 50 kW × 2.5 = 125 kW (recommended headroom)

Because generators are sold in kVA, we convert this using a power factor of 0.8:

→ 125 kW ÷ 0.8 = 156.25 kVA

The nearest standard generator sizes are 160 kVA and 175 kVA. To stay safe and allow for any additional equipment (such as a mini crusher, additional office equipment, and cooling systems, or spare cement silos), we recommend using a 175 kVA generator. This extra capacity ensures smooth operation.

Since your production area is always dusty make sure you choose a generator with canopy.

Generator vs. Grid: Comparison Table

Choosing between a generator and grid power depends on your location, budget, and production goals. Below is a simple comparison to help you understand the advantages and limitations of each option.

Example Power Setups by Block Making Machine Sizes

Each concrete block making machine has its own energy requirements depending on its size, automation level, and additional equipment. Below are real examples taken from our actual machine specifications to help you choose the correct generator size:

Note: These generator sizes include a safety margin to cover power surges and allow for possible expansion. Always verify with your machine supplier before purchasing a generator or finalizing your electrical setup.

Tips and Mistakes to Avoid

Choosing the right power setup is just as important as choosing the machine itself. Below are some of the most common mistakes we’ve seen over the years, along with tips to help you avoid them:

- Choosing a Generator That’s Too Small:

Many buyers try to save money by picking a generator that matches the machine’s power. This is risky. Block machines need extra power when starting, especially during vibration. Always choose a generator that’s at least 2 times bigger than your machine’s total kW — or more, depending on your plant. - Forgetting About Other Equipment:

Your machine is not the only thing that needs power. Mixers, conveyors, cement silos, and even lighting can increase total demand. If you don’t calculate everything together, the generator will be overloaded, causing breakdowns or shutdowns. Ignoring Voltage Fluctuations:

Even with grid power, voltage can be unstable in some areas. This can damage sensitive parts like vibration motors or electrical panels. Always install a voltage stabilizer or surge protection system to avoid long-term damage.No Backup Plan During Power Cuts:

In countries where electricity goes out for hours, like Iraq, Libya, or Nigeria, not having a backup generator can stop production completely. Worse, if mortar stays inside the machine during a power cut, it will dry and cause blockages or damage.

Pro Tip: Consult Your Supplier

Always speak to your machine supplier before finalizing your electrical setup. At Beyazli Group, we help our customers calculate exact power needs for the entire plant — not just the machine.

Conclusion

Power is the foundation of every successful concrete block production line. Whether you choose grid power, a generator, or both, the key is to plan properly from the beginning. Choosing the wrong setup can lead to lost time, damaged equipment, and high repair costs — all of which are avoidable.

At Beyazli Group, we’ve installed over 600 machines in 62 countries. We’ve seen what works and what doesn’t in all types of environments. That’s why we always support our customers in selecting the right power system for their specific machine, location, and production needs.

If you’re unsure about your generator size, grid setup, or total power requirements, contact our technical team. We’re here to help you install with confidence and keep your production running smoothly from day one.