What Products Can You Produce and Sell With a Concrete Block Machine?

One of the biggest advantages of a concrete block machine is its flexibility. With a single machine, you can produce different construction materials simply by changing the mold. This makes it possible to serve different sectors of the construction industry and increase your sales opportunities.

- Hollow blocks:

Hollow blocks are the most common products. Hollow blocks are mainly used for wall construction in houses, apartments, and commercial buildings. They are lighter compared to solid blocks, which makes them easier to handle and cost-effective while still offering good strength.

- Solid blocks:

Solid blocks are heavier and stronger. They are preferred for load-bearing walls, foundations, retaining structures, and industrial buildings where high durability is required. - Paving blocks:

Also called interlocking paving blocks, these are used for sidewalks, driveways, gardens, and public areas. They can be produced in different shapes and colors, which increases their selling price and profit margin. - Curbstones:

Curbstones are always in demand for road construction, parking lots, and urban landscaping. They are commonly purchased by municipalities and contractors, making them a stable source of income. - Other products:

Depending on the mold design, you can also produce items like rain gutters, roof blocks, or hollow core slabs. Adding these products to your catalog gives you more flexibility to adapt to customer requests and market needs.

Please note that some machines can produce only hollow blocks and solid blocks. These details need to be double-checked with the manufacturer before purchasing a machine.

If you want to learn more about products that are produced by concrete block machines, please read the article ‘‘10 Different Products Produced by Concrete Block Machine”.

Who Are the Main Customers in This Market?

A concrete block machine business serves different types of customers, and understanding them is important for building a steady income. Each customer group has different needs, and targeting them correctly helps you sell more products throughout the year.

Construction companies:

These are the largest buyers of concrete blocks. They use hollow blocks and solid blocks for residential, commercial, and industrial projects. Large projects usually mean bulk orders, which guarantee consistent sales.

Municipalities and government projects:

Public projects such as roads, sidewalks, parks, and infrastructure developments require paving blocks and curbstones. Winning contracts from municipalities can bring regular, large-scale orders.

Contractors and private builders:

Independent contractors and small builders are always in need of hollow blocks and curbstones for housing projects, small roads, and renovations. While their orders may be smaller than big companies, they often buy continuously.

Landscaping companies and homeowners:

For decorative paving blocks and garden designs, landscaping companies and even individual homeowners are valuable customers. These products usually bring higher profits because they are sold in special colors and shapes.

By supplying to these different customer groups, a block factory can balance demand across various product types and avoid relying on only one market segment. This diversity is what makes the business more stable and profitable.

Key Factors That Affect Monthly Earnings

The monthly income of a concrete block machine business depends on several important factors. Understanding these will help you calculate profits more realistically and plan your investment better.

Machine type and capacity:

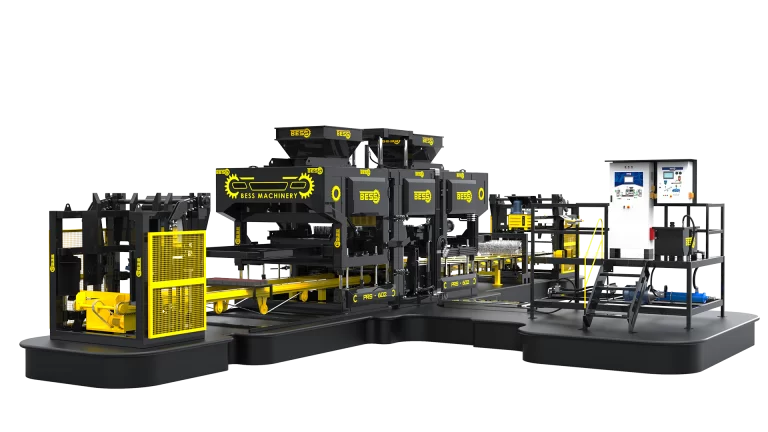

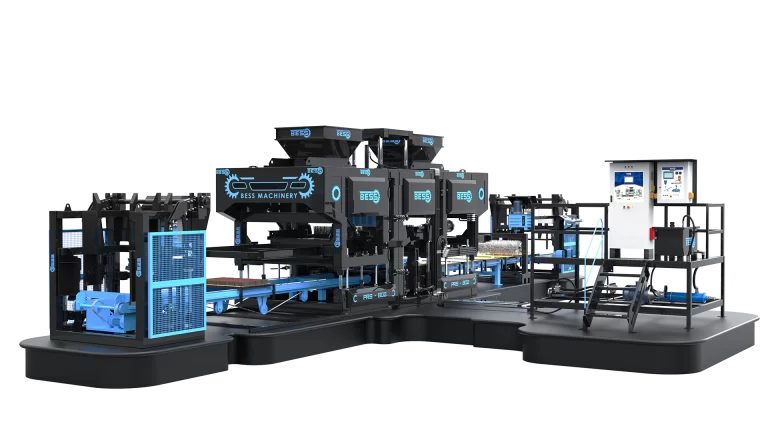

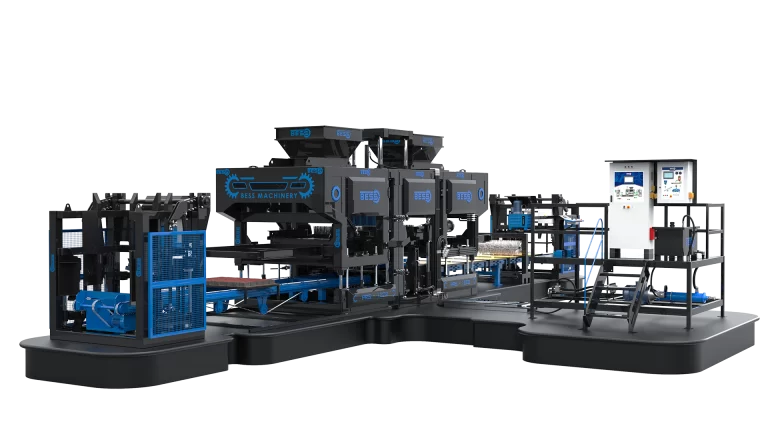

The size and automation level of your machine directly affect production. A semi-automatic machine with lower capacity will naturally produce fewer blocks compared to a fully automatic, high-capacity system. The more you produce, the more you can sell each month. if you want to learn more about the automation system of the machine please read the article ”Semi-Automatic Or Fully Automatic Block Machines, Which One Is The Best for You?”.

Raw material costs:

Cement, sand, aggregate, and water are the main inputs for block production. If you can secure raw materials at competitive prices, your profit margin increases. Rising material costs, on the other hand, reduce your monthly earnings.

Labor and electricity expenses:

Operating the machine requires staff and power. Semi-automatic machines need more labor, while fully automatic machines reduce labor costs but consume more electricity. Keeping a balance between these two expenses is key to maximizing profit.

Market prices of blocks:

Selling prices differ depending on the region, product type, and demand. For example, paving blocks and curbstones often sell at higher prices than standard hollow blocks. Monitoring local market prices helps you choose the most profitable products to produce.

By managing these factors carefully, you can increase your monthly income and run a more sustainable block machine business. If you need a full guide on this matter, you can read the article ”How to Start a Profitable Concrete Block Business in 2025-2026”.

Monthly Profit Calculation For Kenya

Let’s say you are a startup with no experience in this sector, and you have a PRS600 semi-automatic block making machine installed in Nairobi, Kenya. Let’s assume you can run it only with 67% of the real performance in the first few months. The reason for that is that when calculating profits, we always consider the worst-case scenario.

A PRS600 block making machine normally makes 6.000 blocks per shift. Let’s consider only 4.000 blocks per shift.

The selling price of the 200x400x200mm Concrete Block: 80 KSh

Expenses:

cement cost: 19 KSh (₭800/50kg ≈ 16/kg; ~1.2 kg/block)

raw material cost (sand/aggregate): 21 KSh (quarry dust: 1.45KSh/kg – river sand: 2KSh/kg)

worker + electricity + other expenses: 15KSh

Final cost of the block for the manufacturer: 55 KSh

profit from each block: 25 KSh

total profit per month for only 67% performance (worst case): 2,000,000 KSh (≈80,000 blocks/mo × KSh 25)

With a concrete block production business using the PRS600 semi-automatic block making machine, you can earn around 15,000 USD per month in net profit in the worst-case scenario. Suppose you have invested about 150,000 USD for the factory setup (including the machine, molds, equipment, land preparation, and installation). In that case, your return on investment (ROI) will be in approximately 10 months, under conservative conditions.

Considering normal conditions, this period is reduced to 6 to 8 months.

Monthly Profit Calculation For Ghana

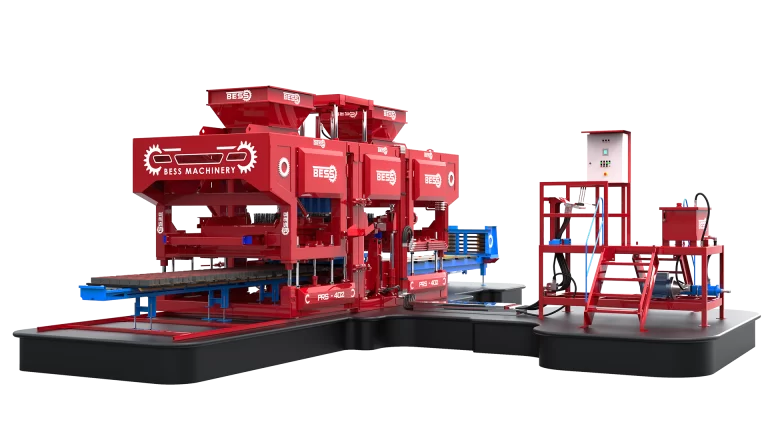

Let’s say you have experience in this sector, and you have a PRS1000 semi-automatic block making machine installed in Accra, Ghana. Let’s assume you can run it with 70% of the real performance in the first few months. The reason for that is that when calculating profits, we always consider the worst-case scenario.

A PRS1000 block making machine normally makes 14.000 blocks per shift. Let’s consider only 10.000 blocks per shift.

Selling price of the 6-inch hollow block: GHS 7.00

Expenses:

Cement cost: 1.6 GHS (0.8 kg cement × 2 GHS/kg)

Raw material cost (sand/aggregate): 1.9 GHS

Worker + electricity + other expenses: 1.40 GHS

Final cost of the block for the manufacturer: 4.9 GHS

Profit from each block: 2.1 GHS

Total profit: 420.000 GHS per month

Note: This is for only 70% performance, 200,000 blocks/month (10,000/day × 20 working days)

With a concrete block production business using the PRS1000 semi-automatic block making machine in Accra, Ghana, you can earn around 38,000 USD per month in net profit. If you invest about 350,000 USD for the complete factory setup (including the machine, molds, equipment, land preparation, and installation), your return on investment (ROI) will be approximately 9 months, even under conservative production performance.

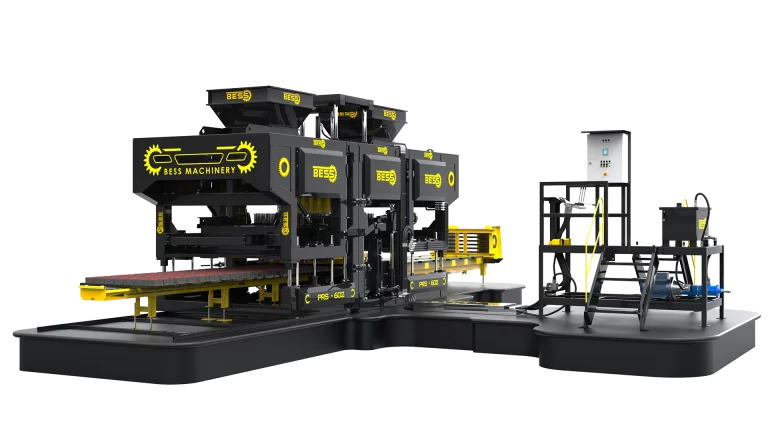

Monthly Profit Calculation For Hungary

For Hungary, let’s consider the PRS1200 fully automatic block making machine, producing 200 × 400 × 200 mm blocks. Since the machine is fully automatic, it operates with minimum labor and can run at around 90% efficiency all the time. With a capacity of about 10,000 blocks per shift, 1 shift per day, 20 working days per month, production reaches roughly 200,000 blocks per month.

selling price of the 200mm block: 650 HUF

Expenses:

cement cost: 168 HUF (≈1.2 kg cement × ~140 HUF/kg)

raw material cost (sand/aggregate): 81 HUF

worker + electricity + other expenses: 181 HUF (lower per block since fewer operators are needed)

Final cost of the block for the manufacturer: 430HUF

profit from each block: 220HUF

total profit per month at 90% performance: 44,000,000 HUF (200,000 blocks × 220HUF)

With a concrete block production business using the PRS1200 fully automatic block making machine, you can earn around 100.000 USD per month in net profit, depending on raw material usage and efficiency. If you invest about 600,000 USD for the complete factory setup (including the machine, molds, equipment, land preparation, and installation), your return on investment (ROI) will typically be reached in 6 months under conservative assumptions.

The return on investment (ROI) in the concrete block business mainly depends on four factors: the capacity of the machine, the selling price of blocks in the local market, the competition, and the total setup cost. A small semi-automatic machine will have a lower investment cost but also lower monthly profit, while a fully automatic high-capacity plant requires a bigger investment but generates much faster payback.

In most countries, investors who buy a semi-automatic machine like the PRS600 or PRS1000 can expect to recover their full setup cost in 6–8 months, even when calculating with conservative production levels. On the other hand, a high-capacity fully automatic line such as the PRS1200 can often pay itself back in as little as 5 months, because the machine operates at high efficiency with less dependence on manual labor.

If you want to make sure you choose the right machine for your business please read ”Top 6 Mistakes to Avoid When Buying a Block Making Machine”.

Of course, these timelines can change depending on local factors such as competition, raw material prices, electricity costs, and market demand. But even with these variations, the concrete block business is considered one of the fastest manufacturing sectors for ROI, making it attractive for entrepreneurs who want to start production and recover their capital quickly.

It’s important to note that these calculations are based on gross profits. Country-specific taxes such as corporate income tax, VAT, or import duties can reduce net earnings and extend the return period. For example, in countries with a 25–30% tax rate, the ROI may increase by several months compared to the initial estimates.

Final Thoughts: Is a Block Machine Business Worth It?

Starting a concrete block production business is one of the most profitable manufacturing opportunities in the construction sector. With a single machine, you can produce multiple products such as hollow blocks, solid blocks, paving stones, and curbstones, all of which are in constant demand for housing projects, road construction, and urban development.

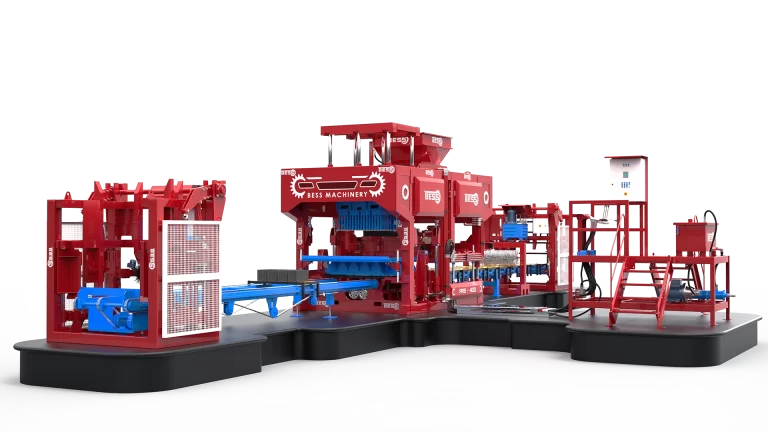

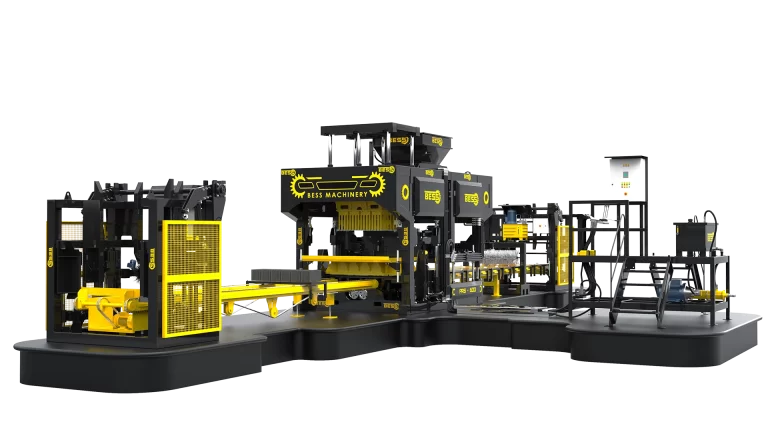

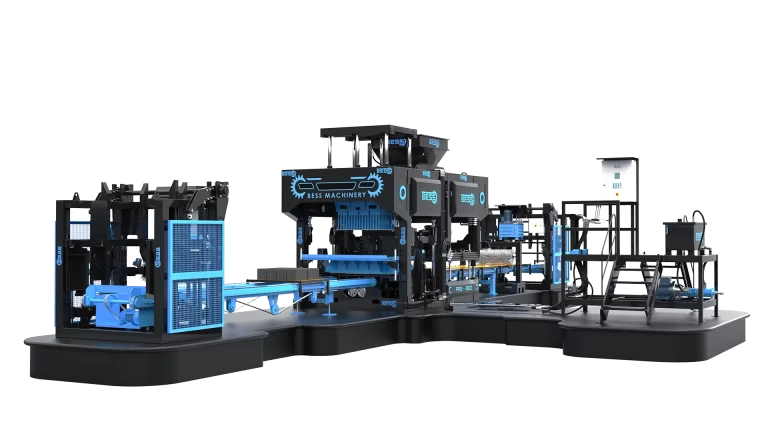

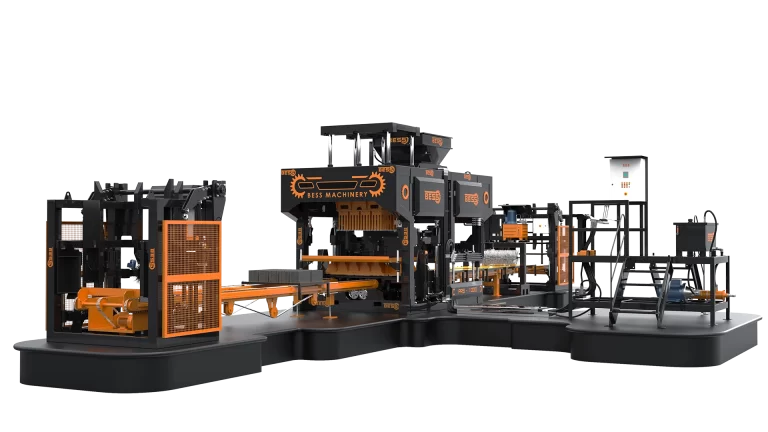

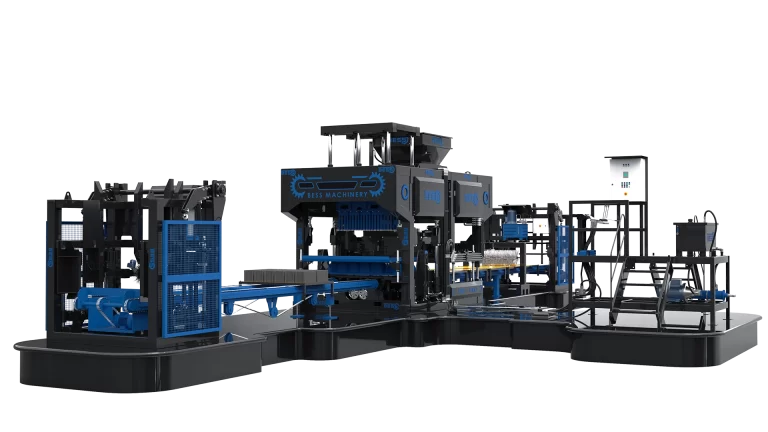

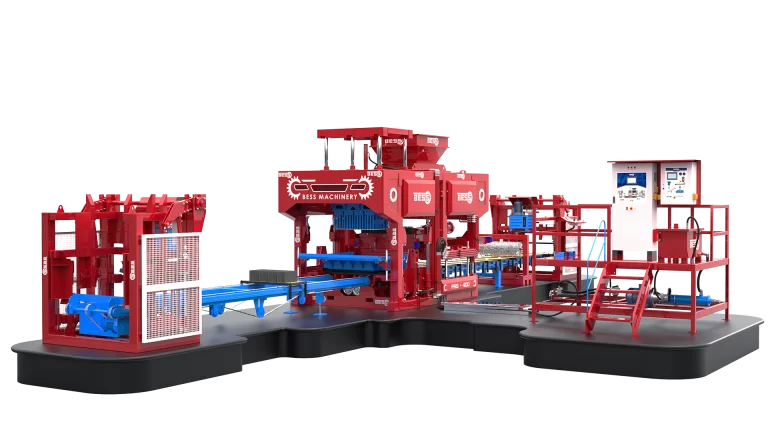

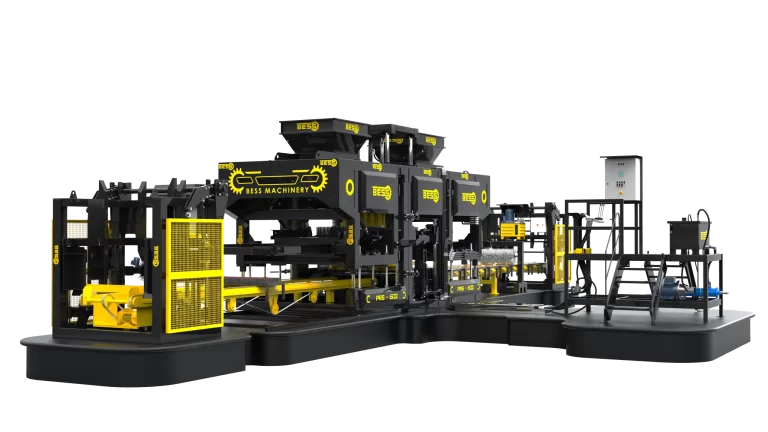

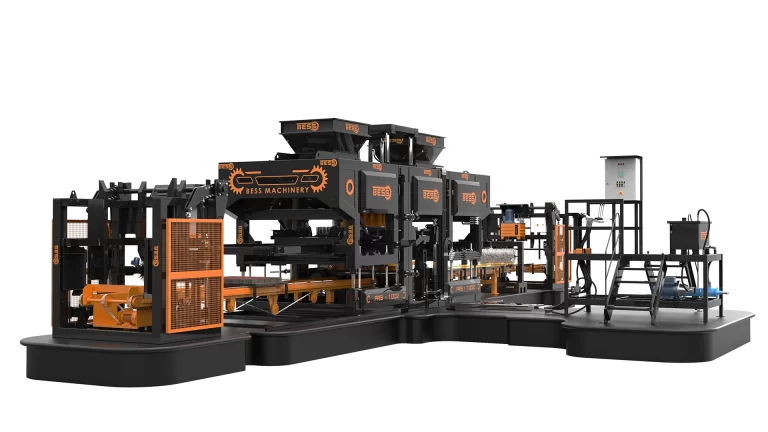

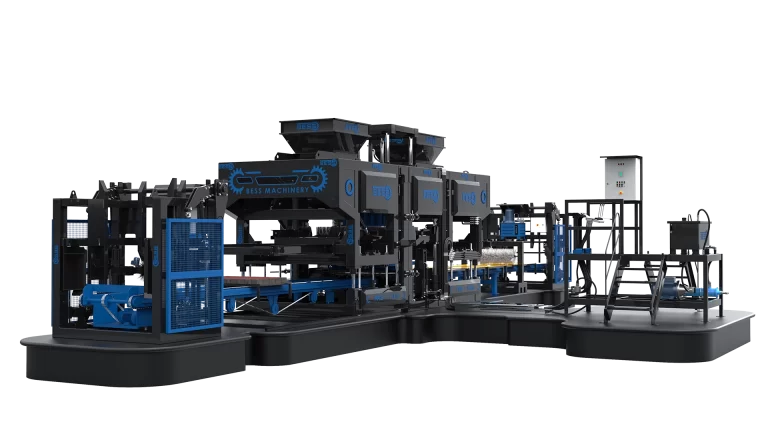

Beyazli Group concrete block machines also provide flexibility. You can start with a semi-automatic machine at a lower investment and expand later. Since concrete block machines work with mortar, a heavy and corrosive material, our machines are built with extra durability and strength to ensure long service life. This way, you avoid the costly breakdowns and headaches that weak machines often cause.

While the exact profits and ROI differ from country to country, the examples from Kenya, Ghana, and Hungary show that block production can generate strong monthly income and recover the setup cost in a relatively short time. For investors looking for a business that combines stability, scalability, and fast payback, a concrete block machine is definitely worth it.

If you wonder about the other hidden expenses that come with the machine please read ”Concrete Block Machine Cost Factors, What You Need to Know Before Buying”.