Investing in a hollow block machine offers many advantages that can improve the profitability of your business. Here are some key benefits to consider:

Increasing The Production Efficiency:

The hollow block machines have high production capacity and allow you to produce at least 4000 hollow blocks in an 8-hour shift. As a result, you can meet high demands and fulfill large orders. You can also run the machine for extra hours in daily basis and get more blocks if there are deadlines for your projects. Since the machine is not labor intensive, the personnel won’t be too tired to do more hours.

Lower Labor Costs:

The hollow block machines provide different automation levels and automize different processes like mixing, molding, and compressing blocks. This means fewer workers are needed to run the machine, which lowers labor costs and minimizes mistakes.

Consistency In Quality And Production Capacity:

Hollow block machines make sure that each block has the same size, shape, and strength. This is crucial for construction projects where reliability and strength are important.

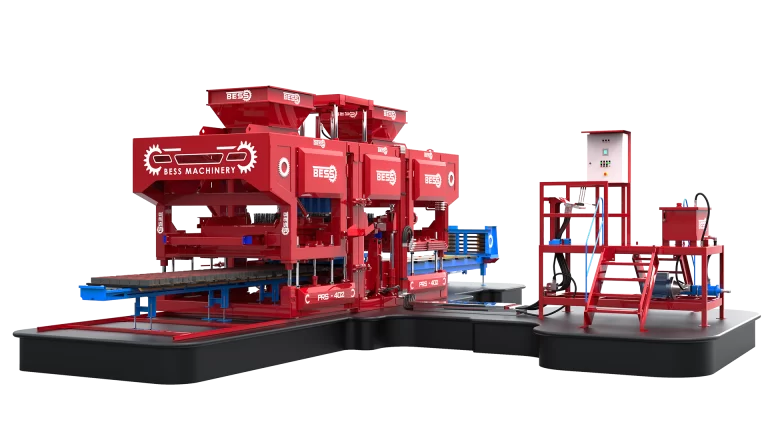

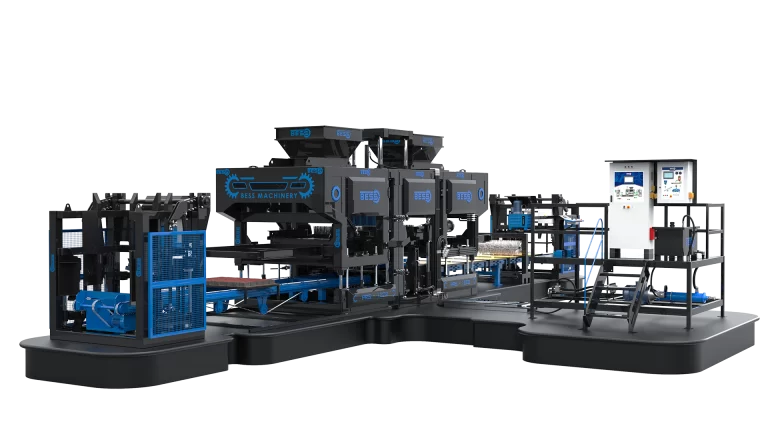

Mold filling and vibration are fully automatic in PRS hollow block machines. This is to guarantee the same quality blocks over time.

Various Options For Production:

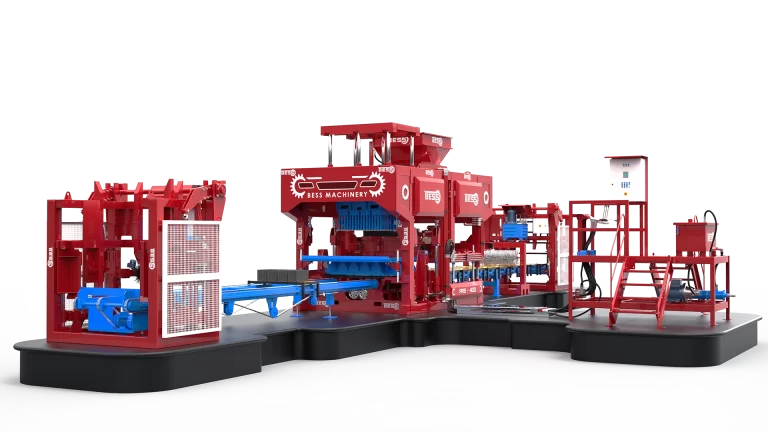

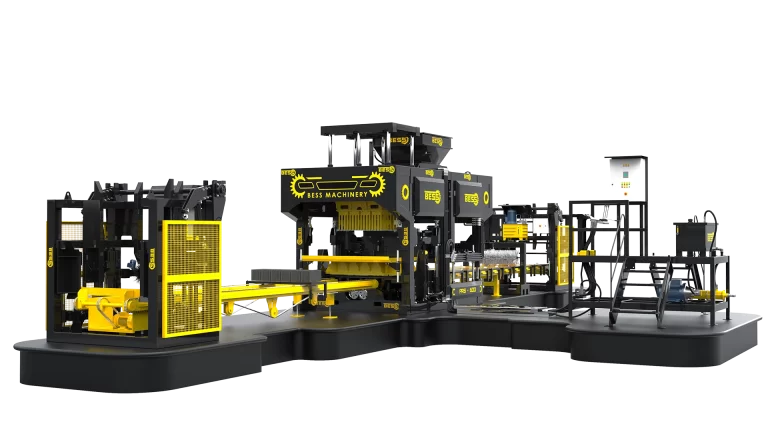

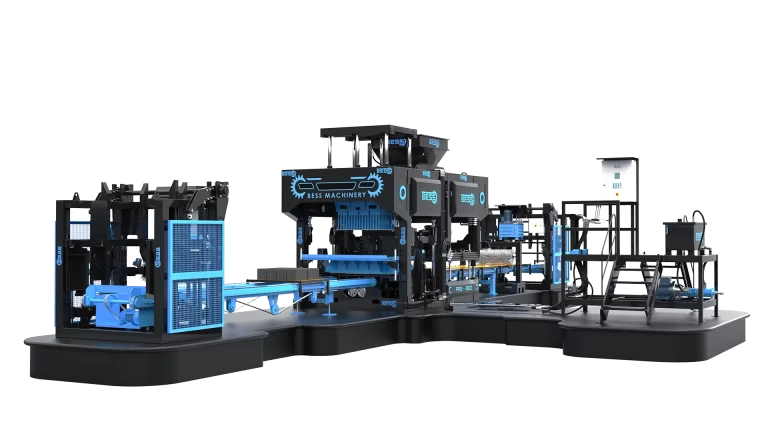

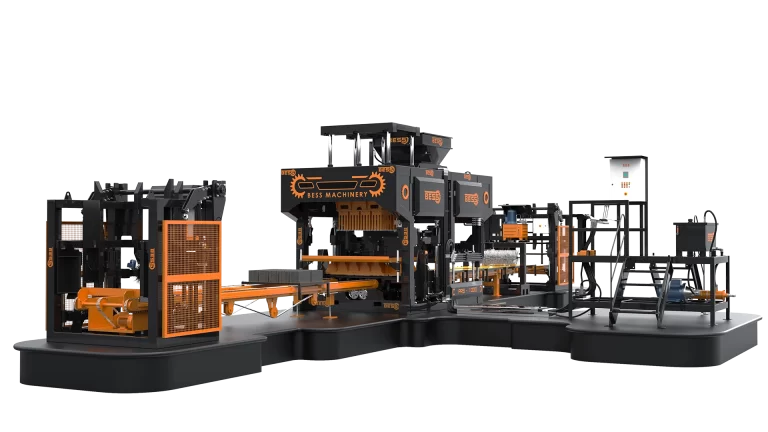

The machine is called hollow block machine, but the production is not limited to hollow blocks only. With investing in a hollow block machine, you can meet the needs of different sectors by producing hollow blocks, solid blocks, paving blocks, and curbstones. as well. All you need to do is to change the mold.

Cost Saving On Material:

Because of stronger vibration and stronger hydraulic pressure, the amount of cement that is used in the mortar is lower. Using lower amounts of cement and getting better quality concrete blocks means more profit. Since the mixing system is automatic, the amount of materials used in the mortar are also accurately weighed before they are added to the mixer.

Return Of Investment

Although buying a hollow block machine may seem costly at first, the long-term benefits are much greater. Lower labor costs, saving on materials, and higher production lead to a faster return on investment. Plus, the machine’s flexibility and durability let you serve various markets, helping to increase your revenue.

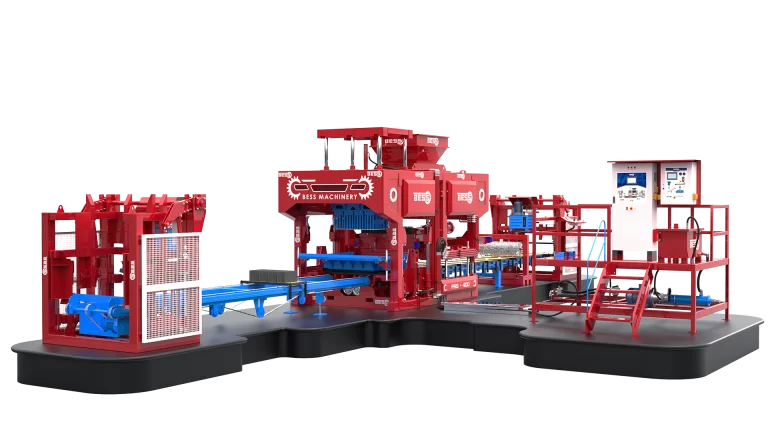

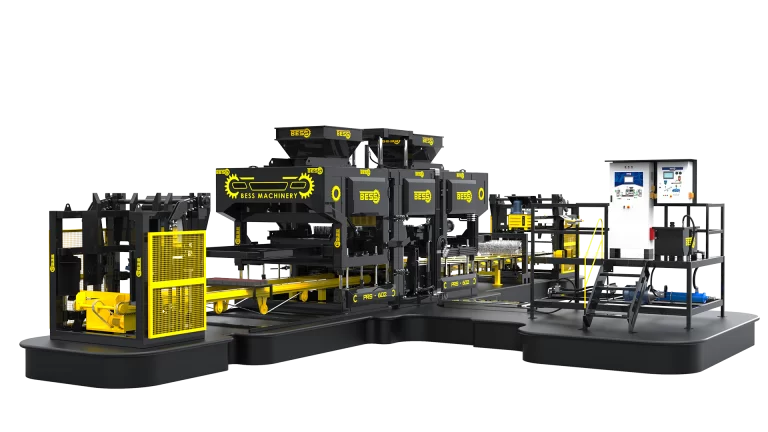

First raw materials like sand and crushed stone are added to the hopper where they are weighed and then added to the mixer.

Cement and water are also measured and added to the mixer. All the material needed to form a mortar are mixed in the mixer for around 3 minutes.

The mortar is then transferred to the machine where it is channeled to the mold and then pressed and vibrated to form a solid shape. The blocks are then cured for 24 hours and then they are ready to use.

This process is explained simply to avoid any confusion. The video below is PRS1000 semi-automatic model and shows the whole process.

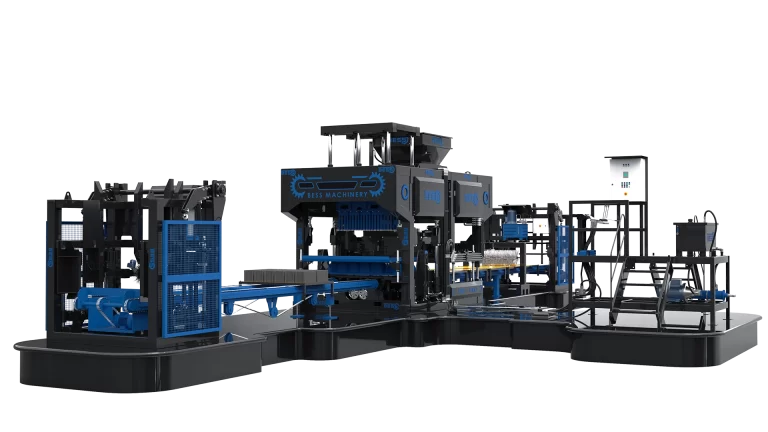

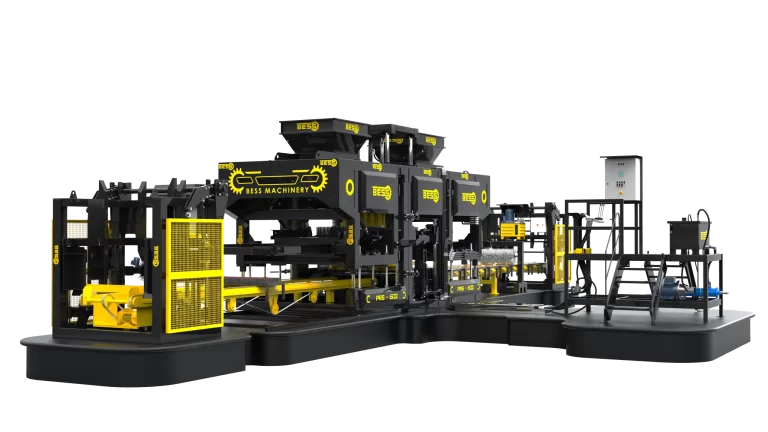

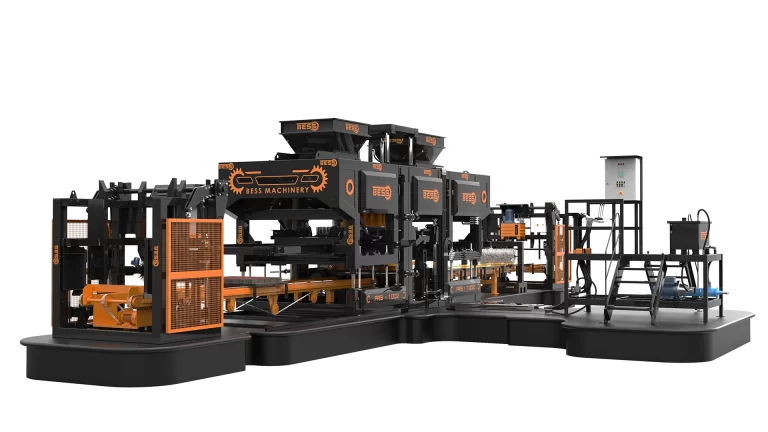

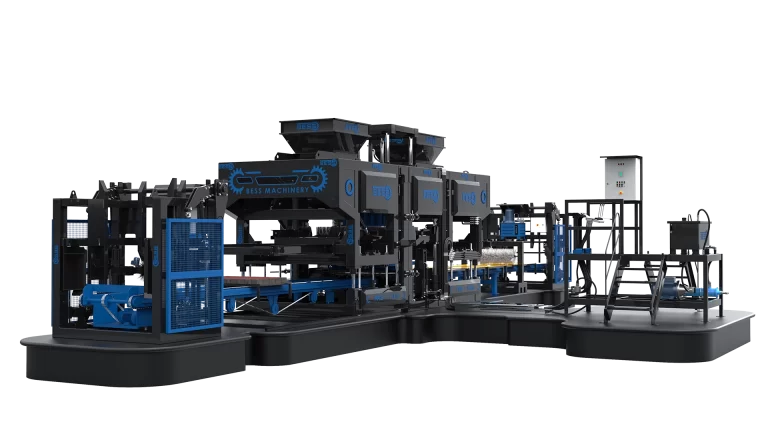

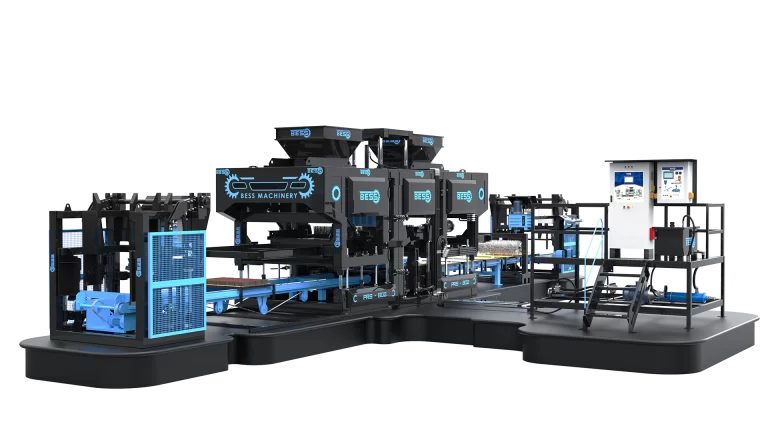

The hollow block machines are available in 3 different capacities.

- Small capacity machines: these machines produce 4000 to 10.000 blocks per shift depending on the size of the block they produce.

- Medium capacity machines: the medium capacity hollow block machines have an output range of 8.000 to 16.000 blocks per shift.

- High-capacity machines: the high-capacity hollow block machines can produce 10.000 up to 22.000 blocks per shift.

Of course, each model has different automation levels to make sure it’s suitable for the project needs.

The main raw materials used to produce hollow blocks are sand, cement, and water. There is also the possibility to produce hollow blocks from the locally available raw materials as well.

The list of the aggregates suitable for producing hollow blocks is prepared separately and with details.

Each raw material type adds special characteristics to the concrete. Depending on the project they can be chosen.

This decision is the crucial decision that will impact on the whole project and future orders that might be received by the clients.

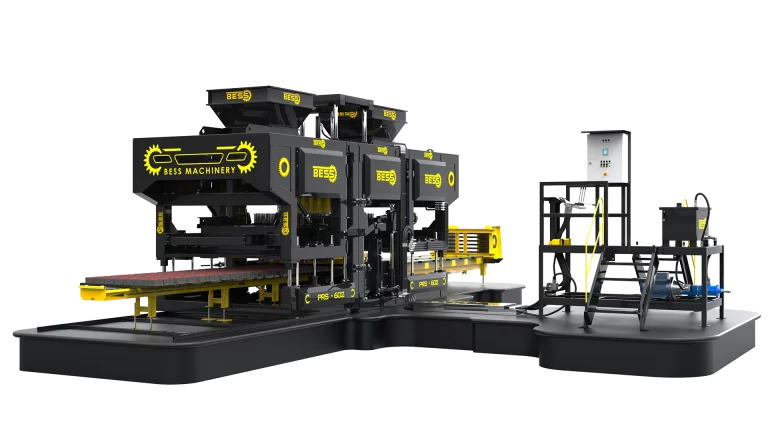

- Production capacity: considering future developments and current budget the right capacity should be chosen. The production capacity is related to the number of projects that are establishing in your area, government projects, city population and other details as well.

- Automation level: the purpose of automation is to minimize the number of workers. In areas with low labor costs, machine owners prefer using more workers instead of automatic and expensive machines. This totally depends on the country you live in.

- Durability and built quality: Hollow block machines are a long-term investment, so ensure the machine is built from high-quality materials that can withstand constant use. Look for machines with durable components like strong vibration systems and hydraulic parts.

- Maintenance and spare parts: Opt for machines that are easy to maintain and come with readily available spare parts. Machines that require minimal downtime for maintenance will help keep your production running smoothly.

- Budget and Long-Term Costs: While the initial cost is important, consider the long-term operational costs such as energy consumption, maintenance, and labor. Choosing a machine that balances upfront investment with long-term savings will give you better value for your money.

By keeping these factors in mind, you can select the right hollow block machine that suits your project’s needs and maximizes your production efficiency.