When it comes to starting or upgrading a concrete block production business, one of the first questions that investors ask is: “How much does a concrete block making machine cost?”

Well, the short answer is: it depends. The price can vary significantly depending on the machine type, production capacity, automation level, mold selection, and additional features.

In this article, we’ll break down the main factors that affect the cost of a concrete block machine so you can make an informed decision, choose the right equipment for your needs, and get the best return on your investment(ROI).

Machine Type

The first and most important factor influencing the price of a concrete block machine is whether you choose a semi-automatic or fully automatic model.

- Semi-Automatic Concrete Block Machines

These machines are generally more affordable and have a lower initial investment cost. However, they require more personnel for tasks like pallet transport and material feeding. They are ideal for markets where labor costs are low and production capacities are required to be small or medium.

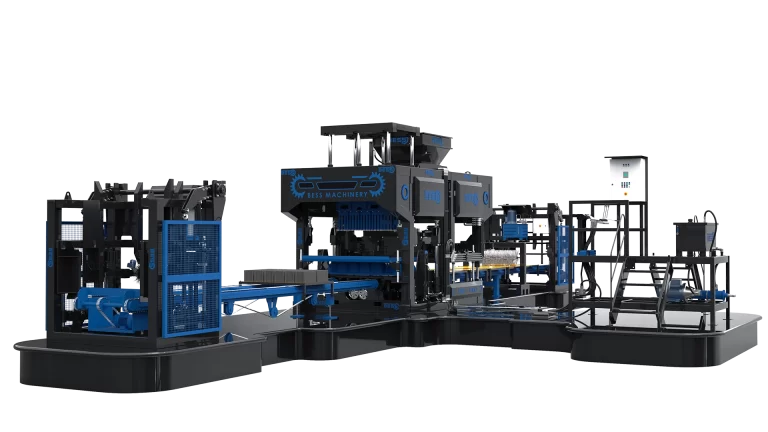

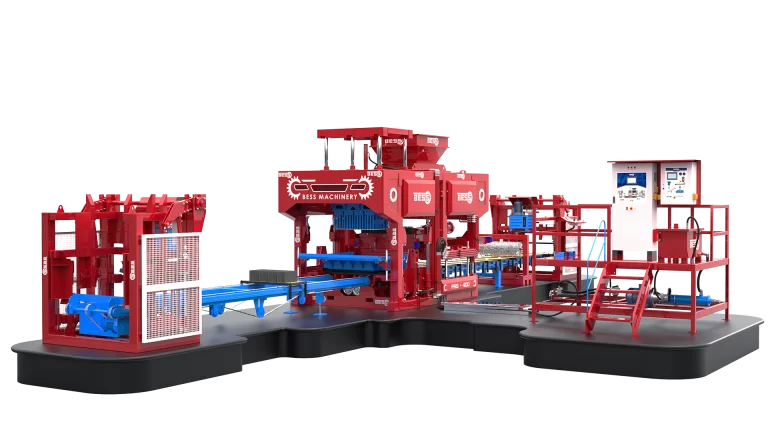

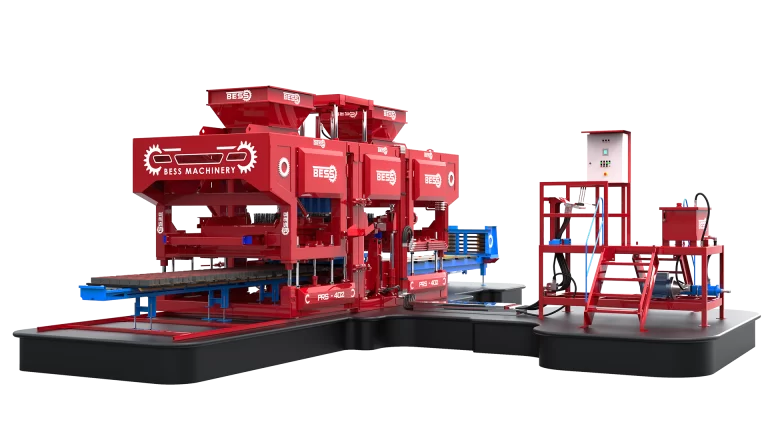

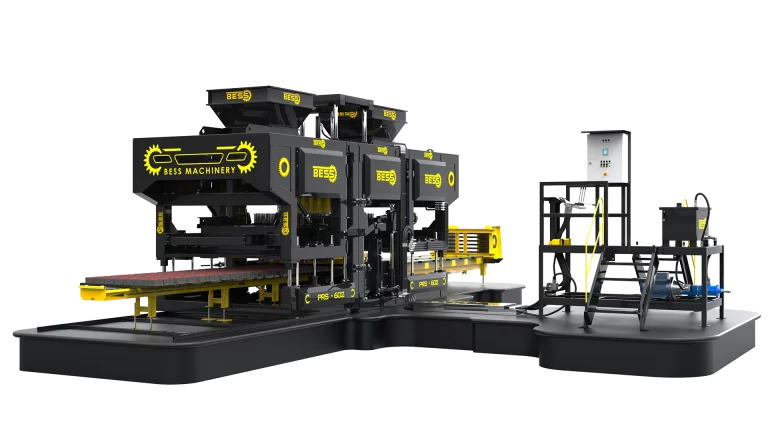

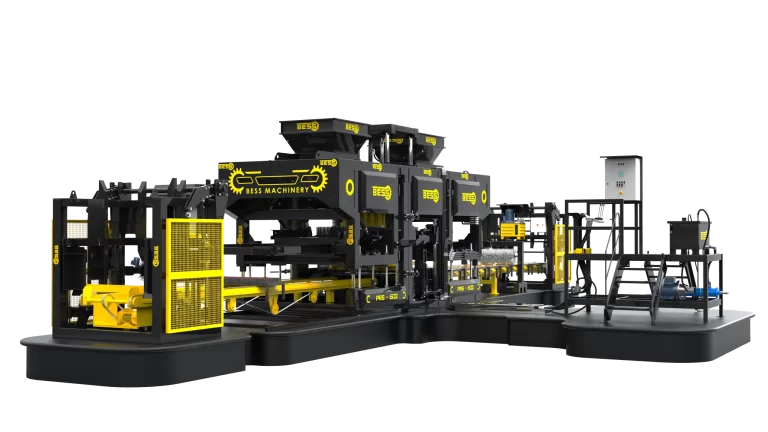

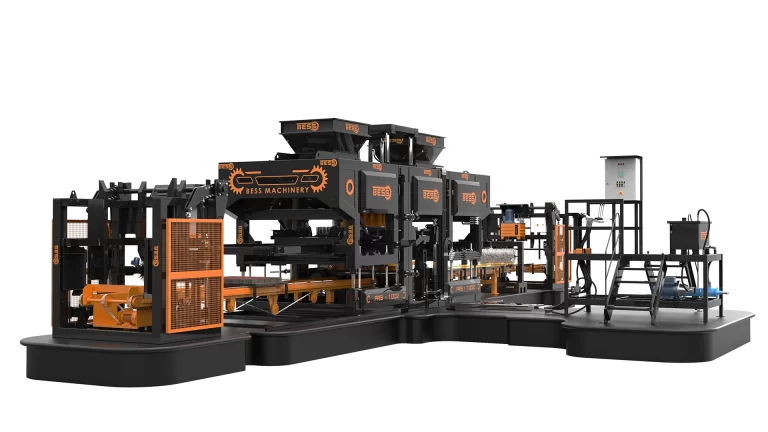

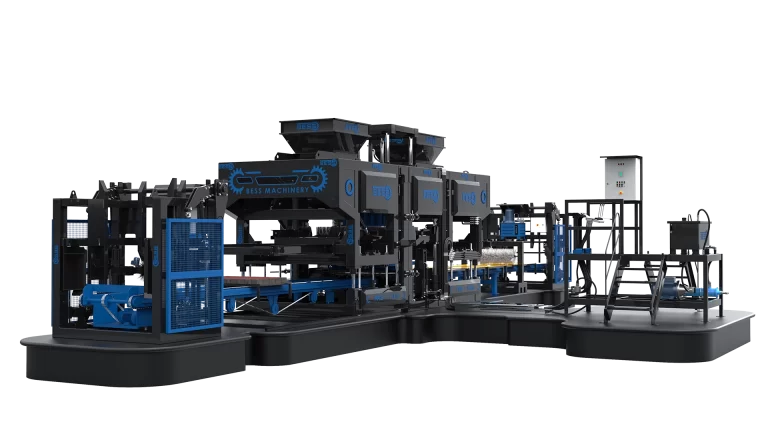

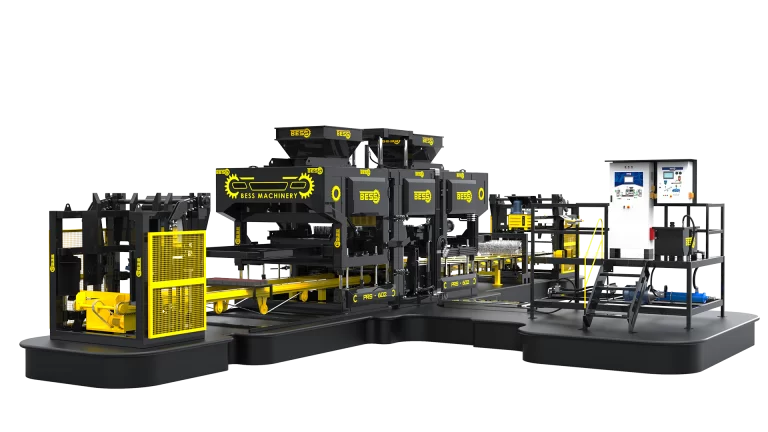

- Fully Automatic Concrete Block Machines

These machines handle most of the work automatically. They need fewer staff, save time, and can produce large quantities with the same quality. They are best for bigger projects or for countries where labor costs are high.

For a detailed comparison, see our article on Semi-Automatic or Fully Automatic Block Machines – Which One Is the Best for You?

Another factor that affects the cost is whether the concrete block machine is stationary or mobile.

- Stationary Machines

These machines are installed in one location and produce blocks on pallets. They offer higher precision, can work with more automation, and are suitable for larger production volumes.

- Mobile Machines

These machines are available in both small and large sizes. Mobile machines produce blocks directly on the ground and need a flat, properly prepared surface.

each option has its own advantages and disadvantages.

Production Capacity

Concrete block machines are made in different sizes to match different production needs. They are available from limited budget small projects to large industrial plants.

- Small Capacity Machines:

Best for local projects or small businesses. They produce fewer blocks per day but have a lower investment cost.

- Medium Capacity Machines:

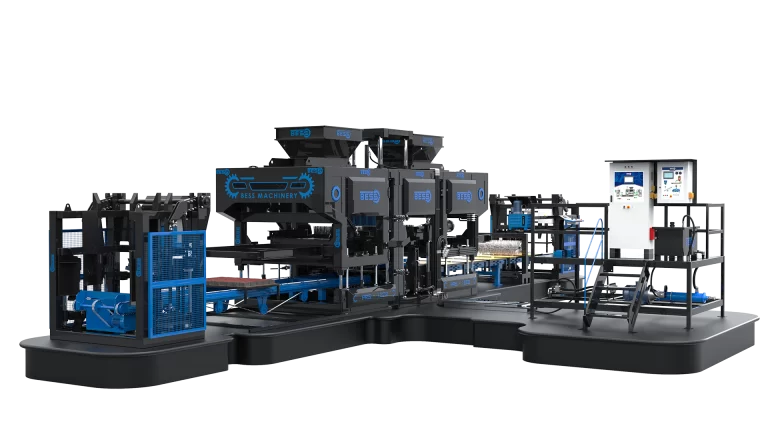

Suitable for supplying larger areas or regional markets. They offer a good balance between output capacity and cost. Our PRS 600 semi-autoamtic concrete block machine is our most popular medium capacity machine.

- High Capacity Machines:

Built for large-scale production. They have the highest output but also require the biggest investment.

In general, the more a machine can produce, the more powerful it needs to be, and the higher its price will be.

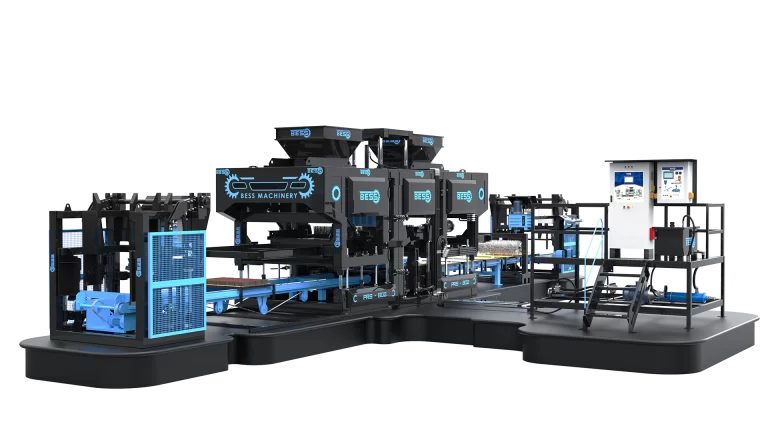

Our PRS 1200 fully autoamtic concrete block machine is our most popular large capacity machine.

Additional Systems and Equipment

In addition to the main block machine, you can add extra systems and equipment to make production faster, easier, and more efficient. Some of these optional equipment can be used with both semi-automatic and fully automatic machines.

Fully Automatic Batching System: Measures and mixes raw materials automatically for consistent quality.

Cement Silo: A Cement silo is used to store cement in bulk. It’s a necessary part for fully automatic batching systems. Bulk cement is cheaper than bagged cement. To ensure consistent quality, follow guidelines from organizations like the Portland Cement Association on selecting cement and aggregates.

Palletizer Robot:Stacks finished products on euro pallets, saving time and reducing labor needs.

Color Mix System: Allows you to produce paving blocks in multiple colors.

Stacking & Packaging Systems: Prepare products for delivery or storage without manual handling.

The more equipment you add, the less manual work is needed and the faster your production will be — but each system will also add to the total investment.

Mold Types & Quantity

Every mold is designed to produce a specific product, such as paving blocks, hollow blocks, curbstones, or other special shapes. In other words for each shape you need a mold.

The number and type of molds you choose will affect the total cost of your investment. generally we have two types of molds.

- Standard Molds: Used for common products like hollow blocks or paving blocks.

- Special Design Molds: Used for unique shapes or custom orders.

Having more molds lets you produce a wider range of products, increasing your market reach. More molds mean more flexibility and profit opportunities, but they also increase the initial investment.

For inspiration on what you can produce, check our article 10 Different Products Produced by a Concrete Block Machine.

Country of Installation

The location where the machine will be installed can also affect the total cost. This is mainly because of:

- Shipping Costs: The farther the destination, the higher the transportation cost.

- Import Taxes and Customs: Some countries have higher import duties on machinery.

- Electrical Requirements: Machines may need adjustments to match the local electricity system (for example, 380V 50Hz or 220V 60Hz).

All these factors can change the final investment amount, even if the machine itself has the same base price.

Hidden or Ongoing Costs to Consider

When planning your budget, it’s important to think about more than just the machine’s purchase price. Running a concrete block production facility involves other costs, such as:

Spare Parts & Maintenance: Regular servicing keeps the machine working smoothly and prevents downtime and potential losses.

Energy Consumption: Electricity or fuel costs will depend on the size and automation level of your machine. The electrical grid is a much cheaper option if it is available.

Operator Training: Staff need training to use the machine efficiently and safely.

Land Preparation: Semi-automatic machines usually require a larger production area because more manual handling is involved, while fully automatic machines are more compact. Preparing the land may include leveling, building a foundation, and creating storage space for products and materials.

Buying Raw Materials: You will need a steady supply of cement, aggregates, and additives. The cost and availability of these materials will affect your overall production cost.

💡 Tip: As a general rule, you should keep around 30% of your total budget for these ongoing and setup expenses. Only about 70% should be invested in the equipment itself. This ensures you can start production smoothly without running into unexpected financial problems.

For more guidance on smart purchasing decisions, see our article Top 6 Mistakes to Avoid When Buying a Block Making Machine.

How to Get the Best Value for Your Investment

Buying a concrete block machine is a long-term investment, so it’s important to focus on value, not just the lowest price. Here are some tips to get the most out of your purchase:

Choose a Reliable Manufacturer: Work with companies that have proven experience and a good track record in the industry.

Consider Long-Term ROI: A slightly higher initial cost can be worth it if the machine lasts longer, works more efficiently, and produces higher-quality products.

Check Warranty and Service Support: A good warranty and strong after-sales service can save you money and prevent downtime in the future.

Match the Machine to Your Market: Buy a machine with the right capacity and product range for your local demand.

Plan for Expansion: If you expect your business to grow, choose equipment that can be upgraded or expanded easily.

Conclusion

The cost of a concrete block making machine depends on many factors, from the type and capacity of the machine to additional equipment, location, and ongoing expenses. By understanding these factors, you can plan your investment wisely and avoid unexpected costs.

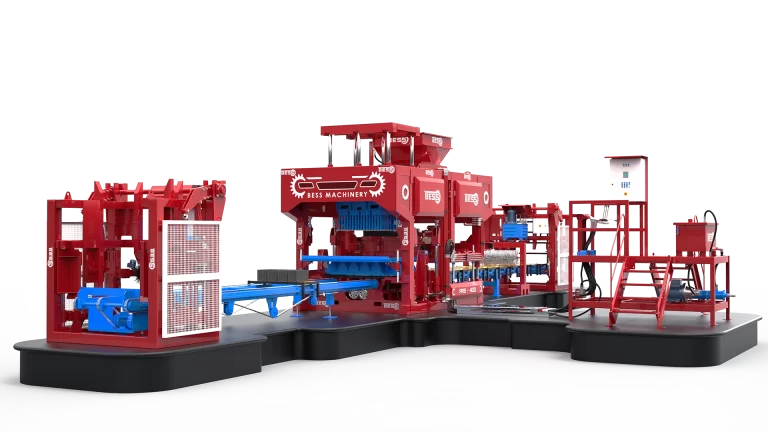

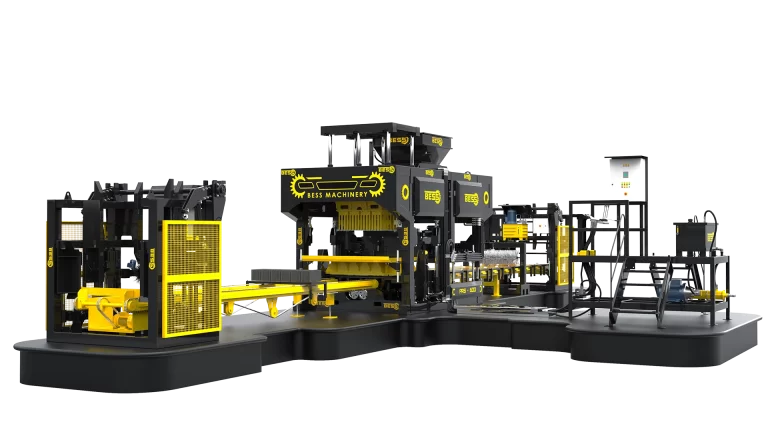

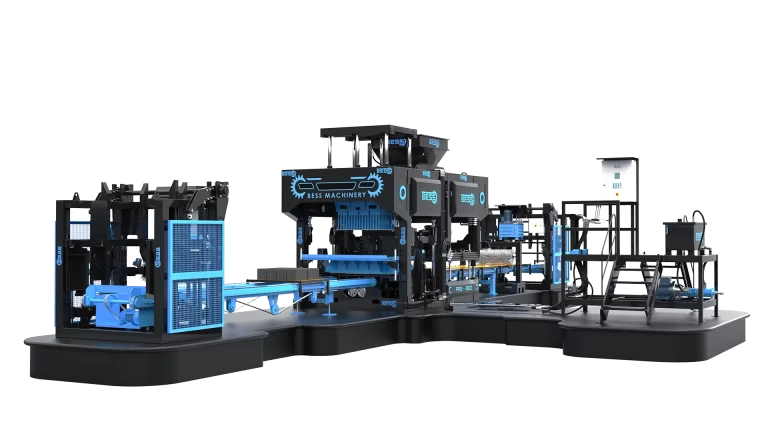

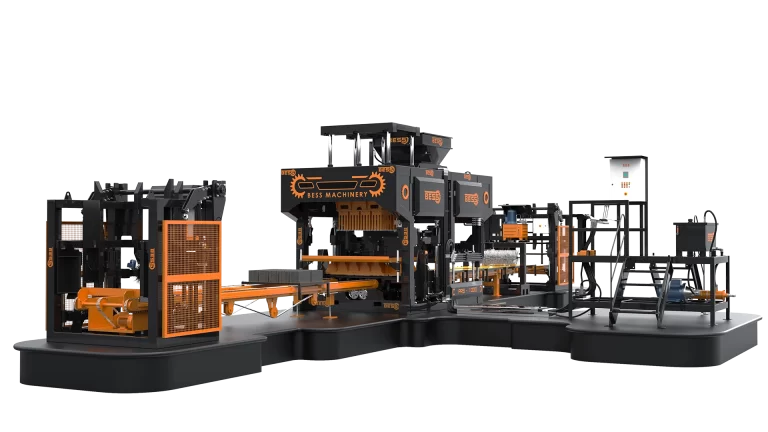

At Beyazli Group, we manufacture a wide range of machines to suit different budgets, production capacities, and project requirements. Our team can help you choose the right setup for your market and provide complete support from installation to after-sales service.

📞 Contact us today to discuss your needs and get a tailored offer for your project.