What Is Concrete In Simple Words?

Concrete is composed primarily of three key ingredients: cement, aggregates (such as sand, gravel, or crushed stone), and water.

When these components are mixed, the cement reacts with water through a process called hydration, binding the aggregates together to form a solid, stone-like material. This process creates a durable and strong substance that can be molded into various shapes before it hardens. This substance is called concrete.

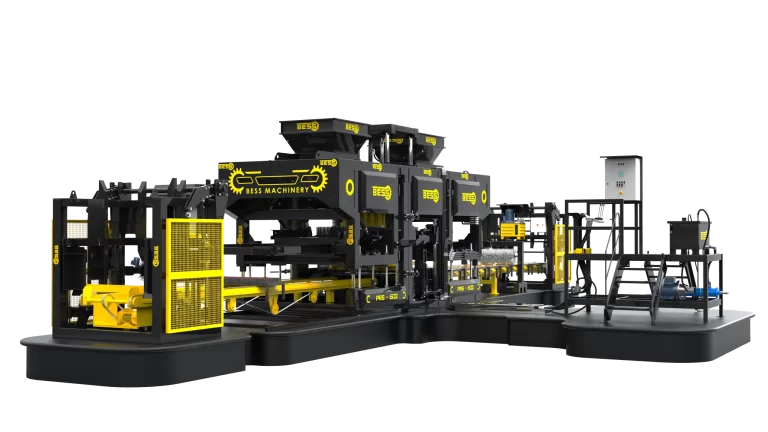

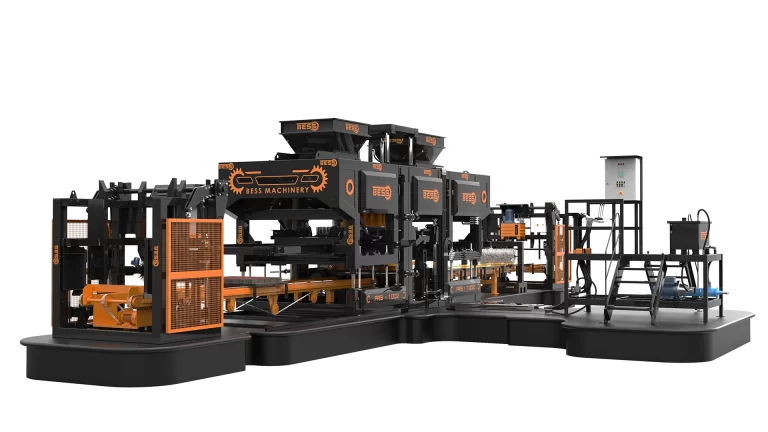

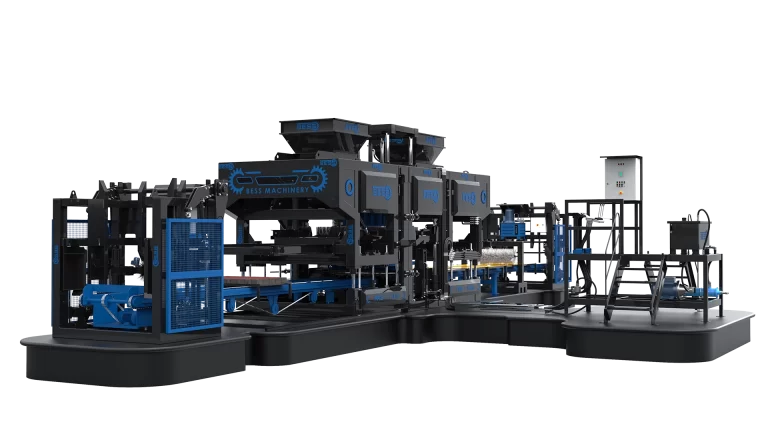

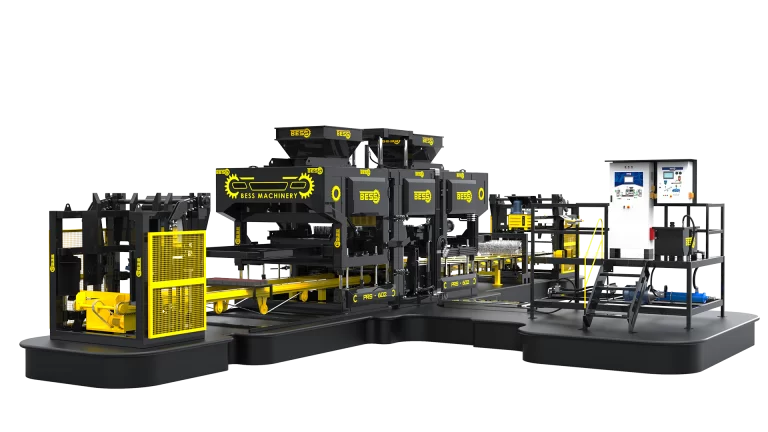

Concrete is the most used material in the construction industry. It is uses range from building bridges and dams to producing concrete blocks for buildings and roads. Our focus is on the different concrete types that can be used for concrete block production.

What are the best concrete block types for concrete block making machines?

- Standard Concrete

- Lightweight Concrete

- High-strength Concrete

- Polystyrene Concrete

- Colored Concrete

Standard Concrete

Standard concrete is a widely used material in concrete block machines. This type of concrete is made from a simple mix of cement, water, sand (fine aggregates), and gravel or crushed stone (coarse aggregates). The cement acts as the binding agent.

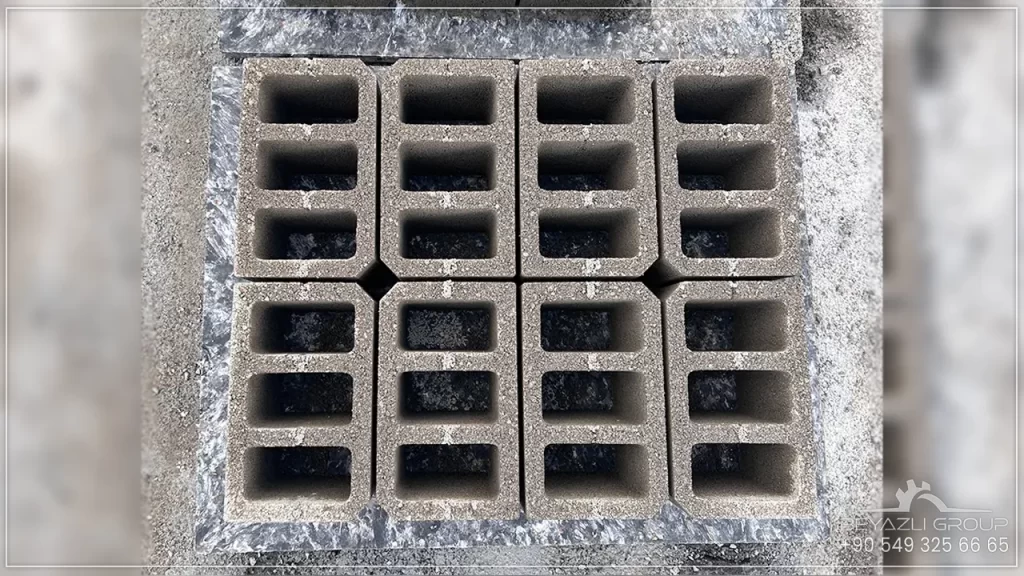

The typical mix ratio for standard concrete used in block machines is 1 part cement, 2 parts sand, and 4 parts coarse aggregates. Water is added to achieve the desired consistency, which is crucial for ensuring the strength and workability of the mix. Once mixed, the concrete is pressed into molds in the block machine and vibrated to remove air gaps and ensure a dense, uniform block.

After molding, the concrete blocks undergo a curing process, where they continue to harden and gain strength. Proper curing takes around 24 hours and involves maintaining the right moisture and temperature levels. The curing process is essential for producing high-quality blocks that are strong, durable, and suitable for various construction applications.

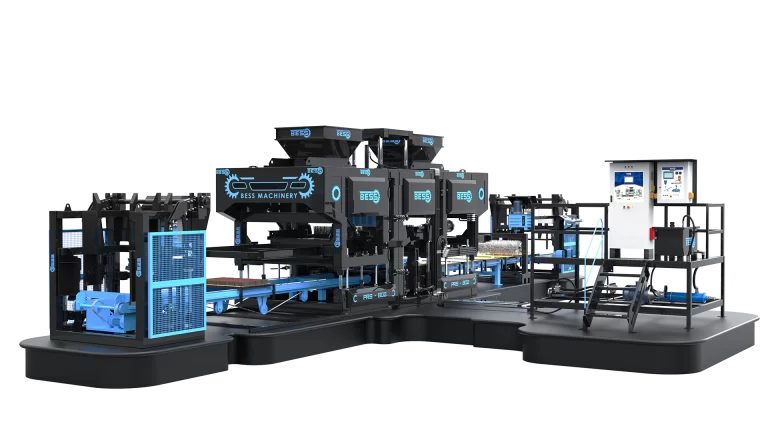

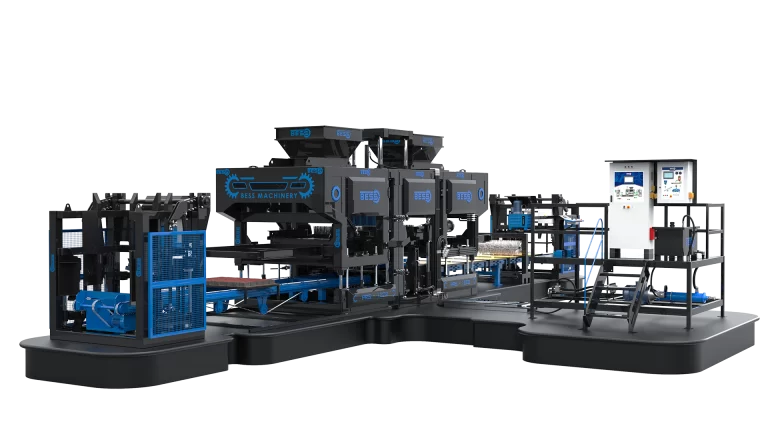

This video shows how Concrete blocks are produced by Concrete block machines with standard concrete.

Lightweight Concrete

Lightweight concrete is often used in concrete block machines to produce lighter blocks that offer better thermal insulation. This totally depends on the availability of the lightweight material. Lightweight concrete incorporates lightweight aggregates such as expanded clay, shale, polystyrene beads, pumice, perlite, and sometimes fly ash. These materials reduce the overall weight of the blocks while maintaining sufficient strength for different applications. The use of lightweight aggregates makes the concrete easier to handle and particularly suitable for non-load-bearing walls, insulation, and energy-efficient buildings.

The mix ratio for lightweight concrete depends on the specific aggregates used and the desired block properties. The inclusion of pumice, perlite, and fly ash not only reduces the weight but also enhances the thermal and acoustic insulation properties of the blocks. Fly ash, in particular, can improve the workability of the mix and contribute to a smoother finish.

In the block production process, lightweight concrete undergoes similar steps as standard concrete, including mixing, molding, and curing.

High-Strength Concrete

High-strength concrete is a special type of concrete used in block machines to produce blocks that require extra durability and load-bearing capacity. This concrete has higher cement percent and lower water-cement ratio, which contribute to its enhanced compressive strength. To further improve performance, high-strength concrete often includes supplementary materials like silica fume, fly ash, or chemical admixtures.

The typical mix for high-strength concrete involves a greater proportion of cement compared to standard mixes, along with carefully controlled amounts of water to achieve the desired consistency without compromising strength. Adding silica fume or fly ash helps to refine the microstructure of the concrete, reducing the number of pores and increasing its resistance to environmental factors like moisture and chemicals.

In block production, high-strength concrete follows the same basic steps as other types: mixing, molding, and curing. Proper curing is particularly important with high-strength concrete, as it ensures the full development of its compressive strength, making the blocks suitable for heavy-duty uses.

Polystyrene Concrete

Polystyrene concrete is a lightweight variant of traditional concrete that includes expanded polystyrene beads (commonly known as Styrofoam) in the mixture. This type of concrete is known for its superior thermal insulation properties and reduced weight, making it an excellent choice for applications where insulation and ease of handling are crucial.

The polystyrene concrete includes cement, water, and expanded polystyrene beads to replace a portion of the traditional sand and coarse aggregates. This mix significantly lowers the density of the concrete while maintaining its structural integrity. The mix ratio varies depending on the desired density and insulation properties, with adjustments made to balance weight, strength, and thermal performance.

During the production process, polystyrene concrete is mixed to ensure an even distribution of the beads, which are then poured into molds within block machines. The lightweight nature of this concrete simplifies handling and reduces the load on structures, while the polystyrene beads enhance the material’s insulation capabilities.

Proper curing is essential for achieving the desired strength and durability of polystyrene concrete. Maintaining appropriate moisture and temperature levels during the curing period ensures that the concrete develops its full potential in terms of performance and longevity.

Colored Concrete

Colored concrete is a versatile variation of standard concrete that includes pigments or dyes to achieve a range of colors and aesthetic effects. This type of concrete is used in block machines to produce blocks with enhanced visual appeal, making it ideal for decorative applications, landscaping, and architectural features.

The color in colored concrete is typically achieved by mixing pigments or dyes into the concrete mixture. These pigments can be either powdered or liquid and are added to the standard mix of cement, water, sand, and aggregates. The amount and type of pigment used can be adjusted to create various shades and hues, allowing for a wide range of color options.

During the production process, the colored concrete is mixed thoroughly to ensure even distribution of the pigments. The mixture is then poured into molds in block machines, where it is compacted and vibrated to remove air bubbles and achieve a uniform finish. The curing process for colored concrete is similar to that of standard concrete, requiring careful control of moisture and temperature to ensure that the color remains consistent and the blocks reach their full strength.

The primary advantage of colored concrete is its ability to enhance the aesthetic appeal of concrete blocks without the need for additional finishes or coatings. This makes it a popular choice for creating visually striking blocks for paving, walls, and other construction elements.