Many people think they need millions to start a concrete block factory. The truth is, you can begin with $100,000 or less if you plan your expenses well. The most important part of the investment is the machine, but there are also other costs you should consider.

Here are the main expenses:

- Machine: the biggest cost and the heart of your factory.

- Molds: for making different block types.

- Pallets: to carry fresh blocks until they are ready.

- Transportation and customs: to bring the machine into your country.

- Land preparation: leveling the ground and getting the site ready.

- Staff: a small team is needed to run the factory.

- Raw materials and cement: sand, gravel, water, and cement for production.

- Generator: needed if electricity is not available.

With careful planning, all of these can fit into a $100,000 budget. Most of your money will go toward the machine, and the machine will decide how many blocks you can produce each day.

Next, we will look at three machine options that match this budget. Each one has a different capacity and is suitable for different business goals.

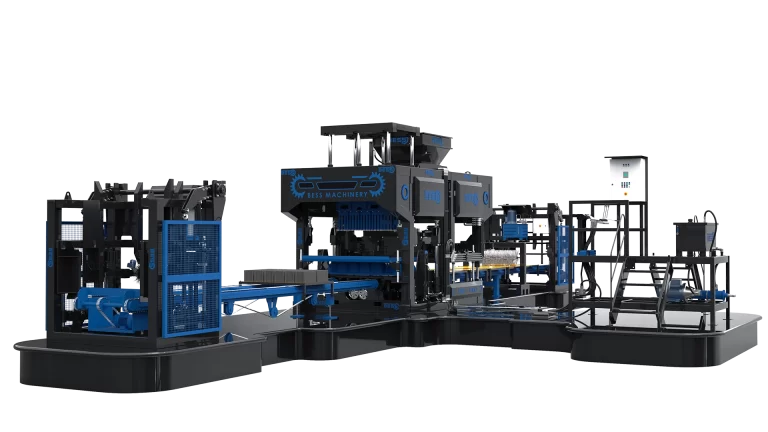

VM3.1 Block Making Machine for First-Time Investors

The VM3.1 concrete block machine is the most affordable way to enter the block-making industry. With a production capacity of 3,000 to 5,000 blocks per shift, it is perfect for supplying local markets without a large investment. This machine can produce hollow blocks, paving blocks, and curbstones, giving you the flexibility to serve different customer needs from the very beginning.

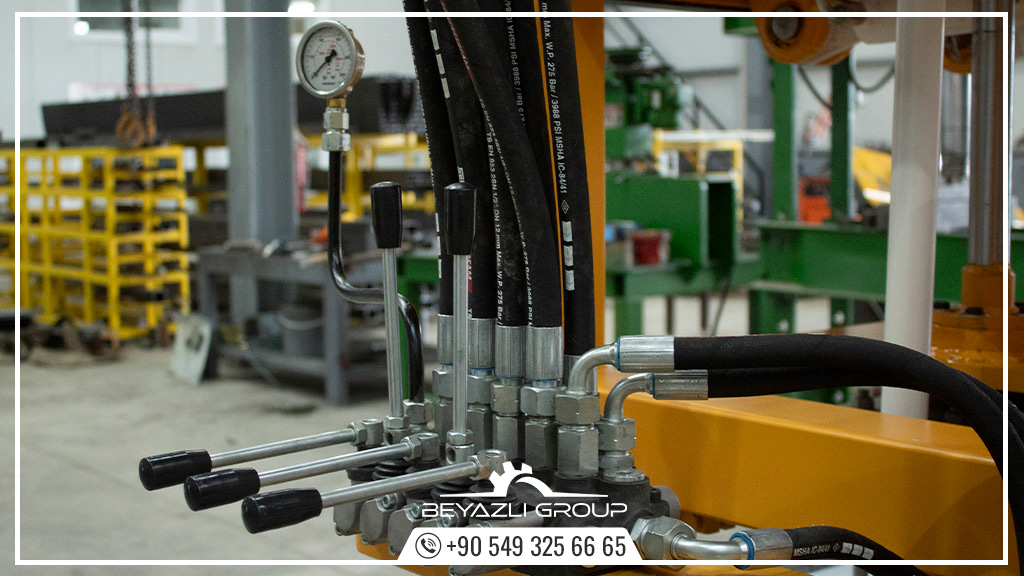

As a semi-automatic hydraulic machine, the VM3.1 is simple to operate and does not require advanced technical knowledge. A team of six people can run the entire plant. Its low power consumption of only 27 kW keeps your electricity costs under control, making it one of the most economical machines for startup businesses.

With a full setup price of only 37,500 USD including one mold, the VM3.1 is a smart choice for first-time investors, small towns, and markets with lower demand. It allows you to start production with minimum risk while building a strong foundation for future growth.

The VM3.1 works with 60 x 70 cm pallets, and around 1,000 pallets are needed for continuous production. Since these pallets are smaller, they are more affordable compared to larger sizes, which helps reduce your startup costs. Another big advantage of the VM3.1 is the simple site preparation — it does not require a complicated foundation or long installation process. This machine is designed as a plug-and-use system, meaning you can start production quickly with minimum setup.

If you wonder how much profit you can earn from a block making machine per month you can read our article ”How Much Can You Earn Per Month With a Concrete Block Machine Business?”

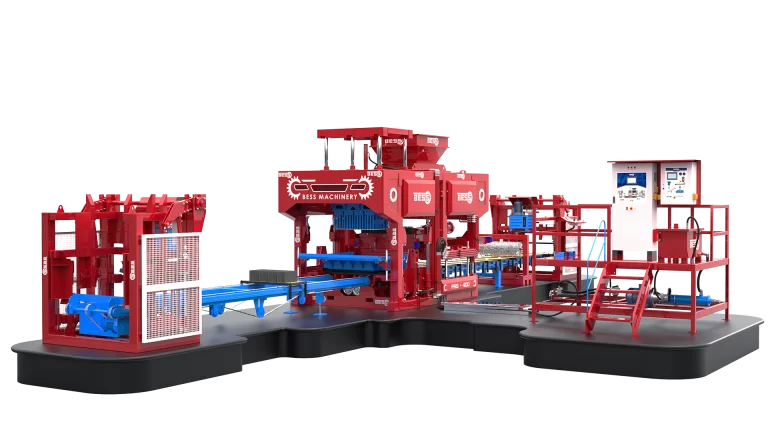

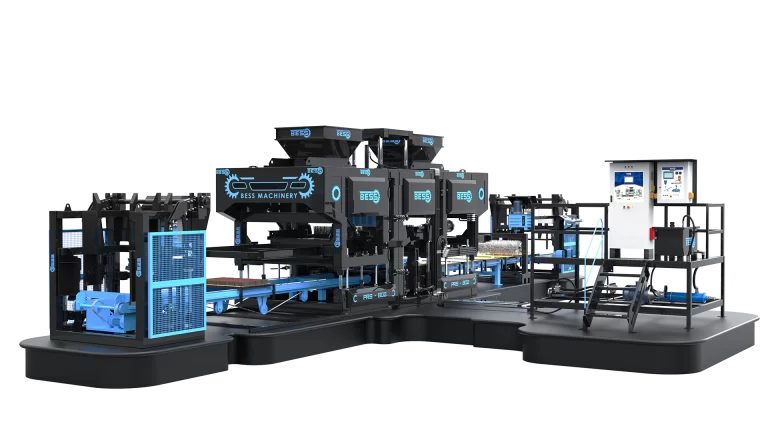

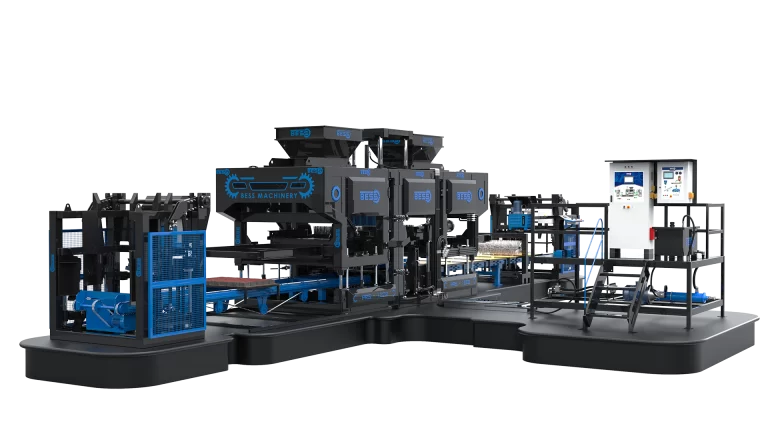

Vess Eco 4.12 Block Making Machine for Higher Capacity Demand

The Vess Eco 4.12 is designed for investors who want more production power while keeping their budget under control. With a capacity of 4,000 to 7,000 blocks per shift, it is the right choice for businesses that have higher market demand than an entry-level machine can cover. This machine can produce hollow blocks, solid blocks, paving blocks, and curbstones, giving you the flexibility to meet different customer needs.

Before making your investment, it’s also important to know what to avoid during the buying process. Check out our guide on the Top 6 Mistakes to Avoid When Buying a Block Making Machine.

Like the VM3.1, this model is also a semi-automatic hydraulic machine, which makes it simple to use and reliable in daily operation. A team of six people is enough to run the full plant. The machine applies strong hydraulic pressure to produce blocks with high strength and smooth surfaces, ensuring your products meet professional construction standards.

The power consumption of 31 kW makes it slightly stronger than the VM3.1, but still efficient and affordable for continuous production. With a price of 63,000 USD including one mold, the Vess Eco 4.12 is a great investment for companies that want to scale up without moving directly to a fully automatic system.

This machine works with 60 x 95 cm pallets, and around 1,000 pallets are needed to keep production running smoothly. The larger pallet size means you can press more blocks per cycle, which increases efficiency. For entrepreneurs aiming to serve larger towns, growing construction markets, or customers with higher volume needs, the Vess Eco 4.12 offers the perfect balance between capacity, cost, and flexibility.

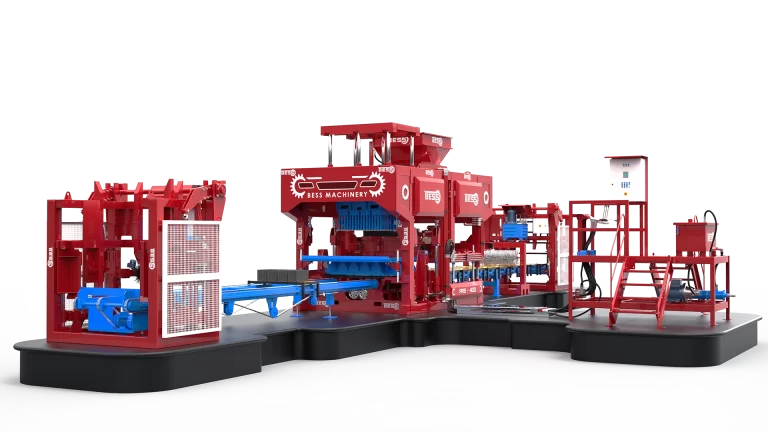

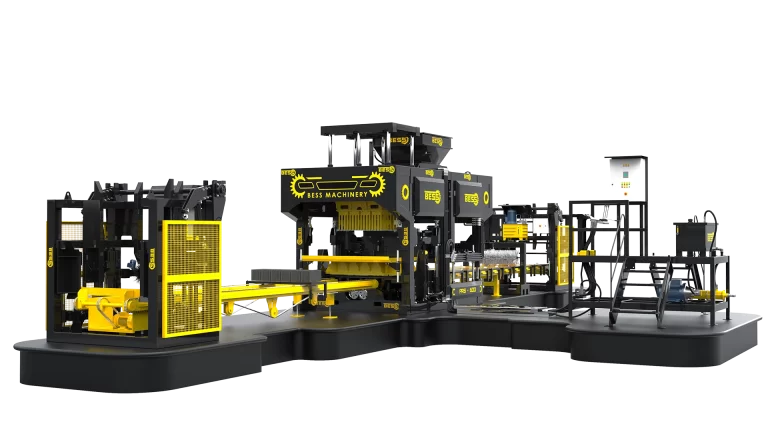

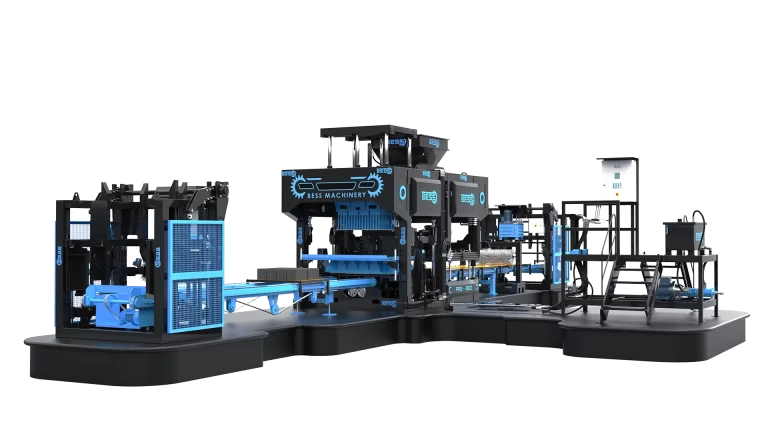

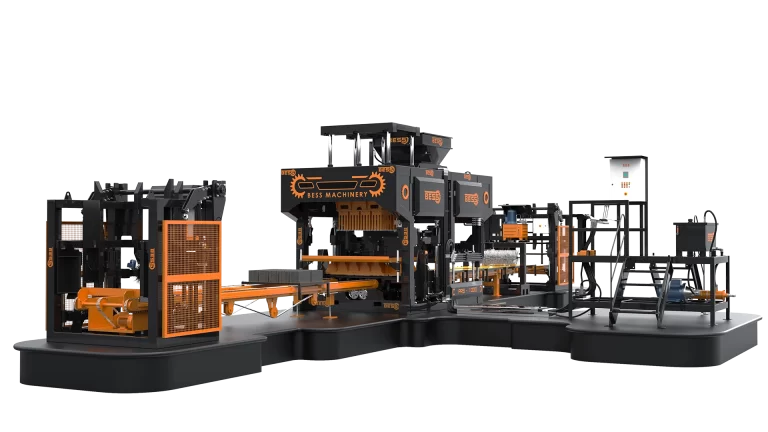

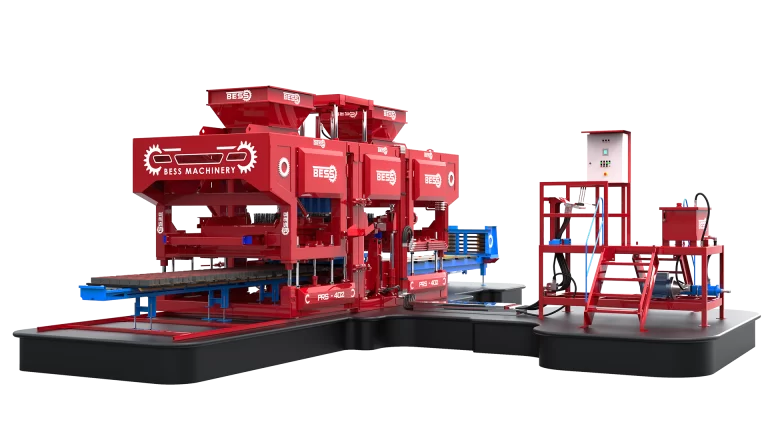

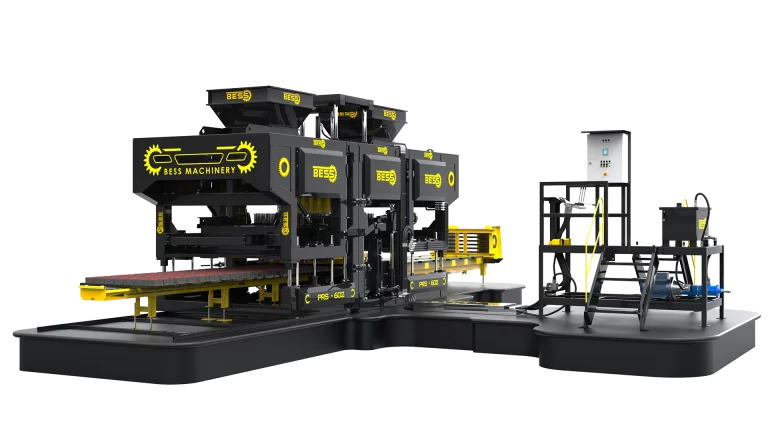

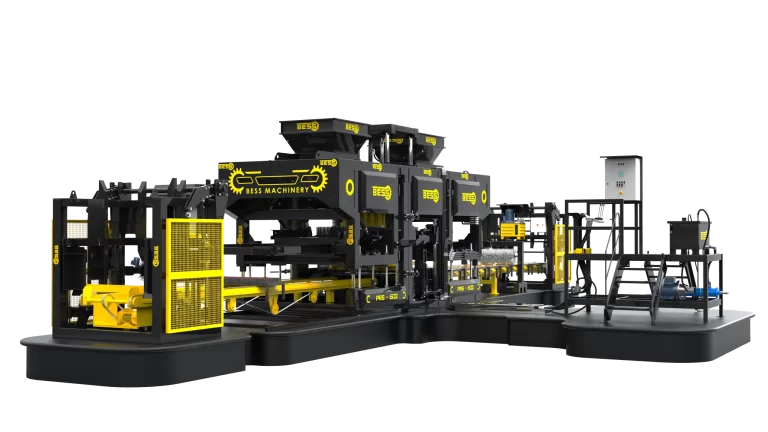

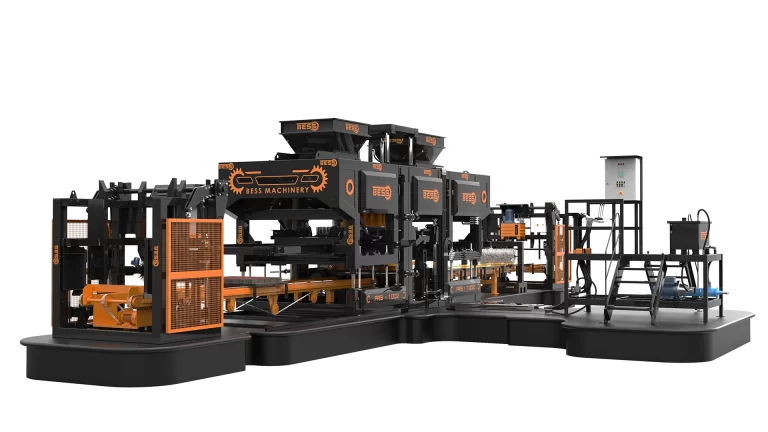

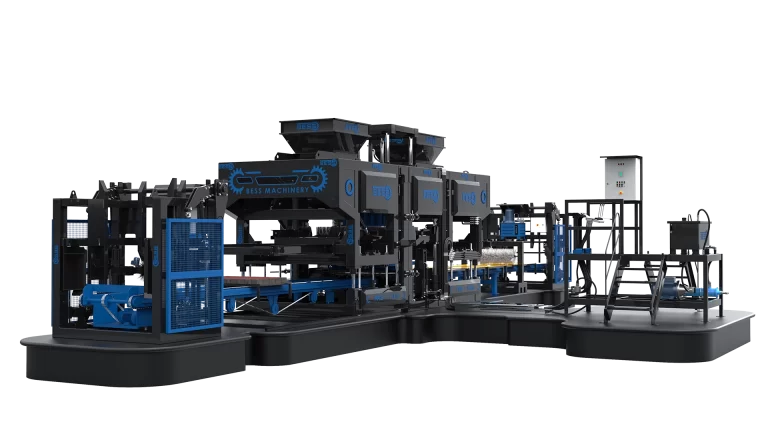

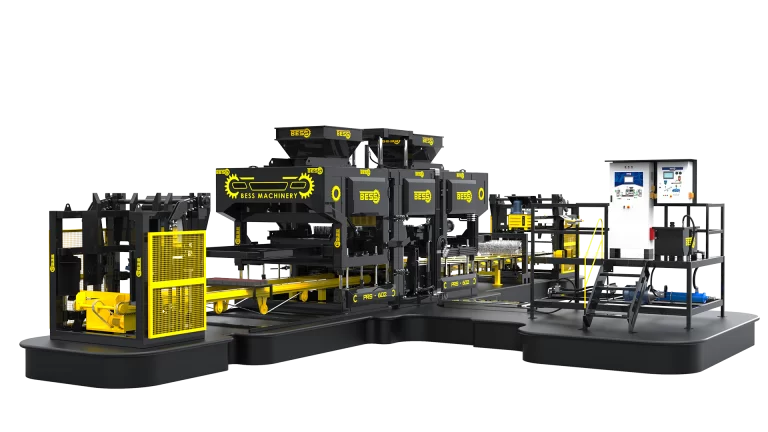

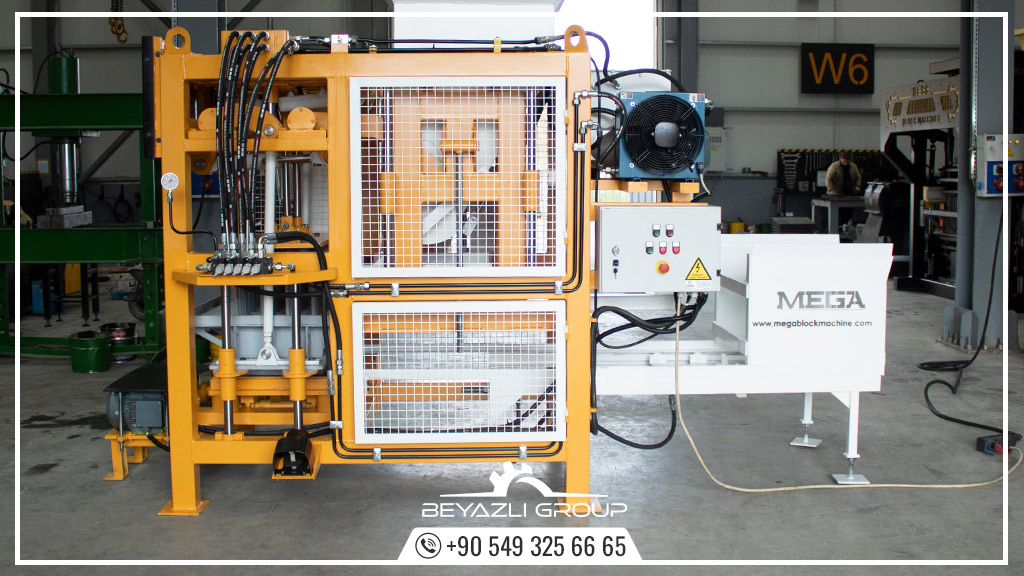

PRS600 Heavy-Duty Block Making Machine for High-Capacity Production

The PRS600 is a heavy-duty industrial machine built for investors who need maximum strength and reliability. With a capacity of 6,000 to 12,000 blocks per shift, it can easily handle large orders and serve high-demand markets. Like the smaller models, it can produce hollow blocks, solid blocks, paving blocks, and curbstones, but at a much larger scale.

If you’d like to explore the wide range of products that can be manufactured with machines like the PRS600, take a look at our guide on the 10 Different Products Produced by a Concrete Block Machine.

This model is a semi-automatic machine with advanced features. While general operation is semi-automatic, the vibration system and mold filling process are fully automatic, which improves block quality and consistency. A team of seven people is enough to run the whole plant. The 50 kW power consumption is higher than smaller models, but necessary for the performance it delivers.

The machine is sold at 92,000 USD with one mold, and it works with 50 x 135 cm pallets. About 1,000 pallets are needed for continuous production. Because of the larger pallet size, you can carry more blocks per cycle, which increases efficiency. The chassis is extremely strong, built to work in tough environments, and comes with extra cooling systems that protect the vibration motors during long production hours.

Investing in the PRS600 is best for entrepreneurs with a higher budget who want a very reliable, high-capacity machine. However, when you add the cost of pallets, transportation, and site preparation, the total investment may go slightly above the initial $100,000 budget. For buyers ready to make that extra step, the PRS600 offers unmatched durability, performance, and the ability to meet heavy production demands.

Starting a concrete block factory with $100,000 or less is possible, but the right machine makes all the difference. The VM3.1 is the ideal choice for first-time investors and small markets, the Vess Eco 4.1.2 serves businesses with higher demand and growth potential, while the PRS600 is the best option for investors who want a strong, reliable, and high-capacity machine.

Each of these models can fit into your budget with careful planning, and each one allows you to start production with confidence. The key is to match the machine to your market size, your financial plan, and your growth goals.

If you are considering starting your own block factory, the next step is simple — contact us today to get a personalized quotation and a complete factory setup plan based on your budget and market demand.